Chery A15. Manual - part 260

Section Six. Exhaust Emission Control Component

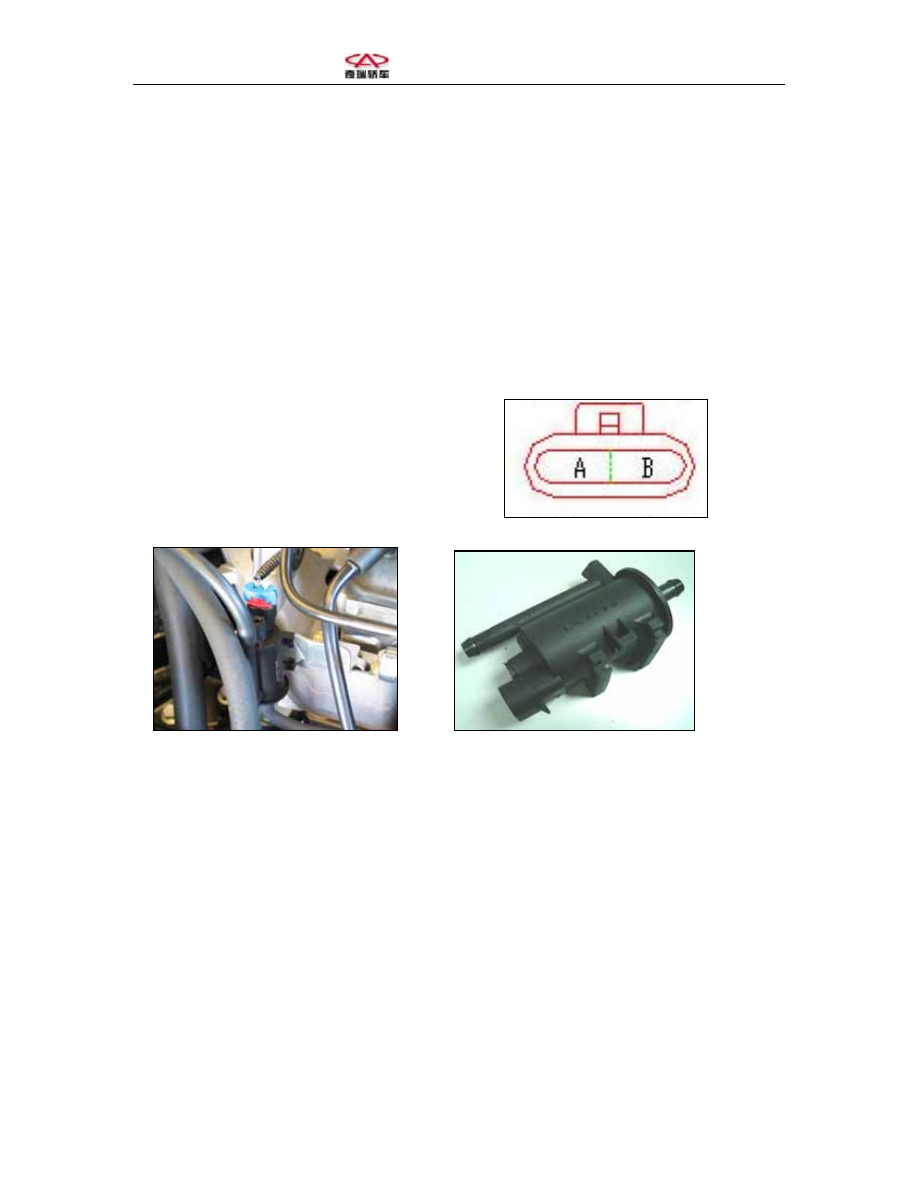

One. Charcoal canister cleaning solenoid valve (ECP)

1. Functions and principles

The ECM controls the gasoline flow into the intake manifold by the cleaning solenoid

valve; for the ECM’s output pulse square wave, gasoline steam flow and the duty ratio of

the control pulse square wave are linear to each other.

The ECM will change the cleaning timing and speed of the charcoal canister as per the

engine speed and load.

Wiring terminal: A-ECM, B- +12V;

Fixing: in the front right position of the engine and between the fuel steam charcoal

canister and intake manifold.

2. Component parameter:

Working voltage: 8~16 V

Ultimate voltage: 25 V (<60 S’)

Working temperature: -40~120℃

Impedance: 19~22

Ω

Inductance: 12~15 mH

3. Fault diagnosis

Tips: All the following judgments are based on the normal operation of the vehicle, wire

harness and other system components.

The faults are discovered by the system and displayed on the diagnostic instrument; self

damage, blocked charcoal canister and wrong fixing of pipes.