Chery A15. Manual - part 249

2. Fuel supply system control logics

- Logic of fuel pump startup

The fuel pump will run for 0.5s after the ignition switch is turned on. The pump will stop if no

valid 58X signals are detected; the engine starts running; the fuel pump starts running after ECM

detects two valid 58X signals.

- Logic of fuel pump shutoff

The fuel pump will stop running after the turning speed signals have been lost for 0.8s.

Start the pre-injection

The pre-injection will only inject once during normal startup. The conditions for pre-injection

startup are as follows:

- The engine starts running (ECM detects at least 2 valid 58X signals)

- Fuel pump relay is actuated

- Fuel pump working time exceeds the delayed voltage accumulation period

- No pre-injection before

Once the above conditions are satisfied, the pre-injection will be carried out in all cylinders.

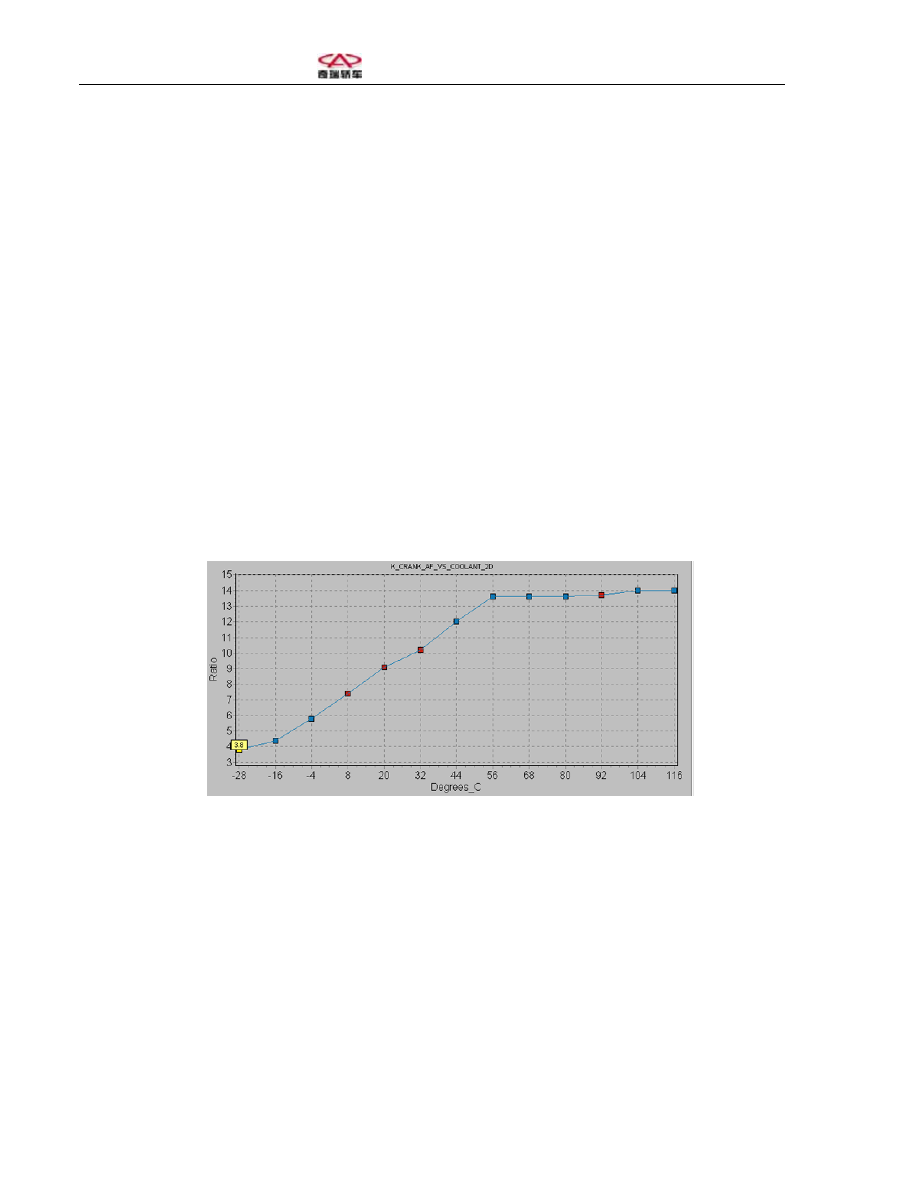

3. Engine startup performance

Engine startup performance refers to the engine startup performance at various ambient

temperatures.

Startup Temperature and Air-fuel Ratio