Chery A15. Manual - part 213

(3). Fix parking brake dragline on parking brake arm drag, and assemble brake shoe

onto brake cylinder wheel.

(4). Fix lower retracing spring, and regulate wedge spring and retracing spring.

(5). Assemble brake drum and rear wheel hub bearing.

(6) Fully operate brake pedal for several times to set brake shoes in normal working

position

(II). Replacing Brake Strip

Check brake strip for oil stains, and sand with a piece of sandcloth if any. In case

brake strip is worn to the limit, it shall be replaced together with brake shoes.

Note: When replacing brake strip, new brake strip of the same quality made by

the same manufacturer shall be used.

(III). Checking Rear Drum Brake

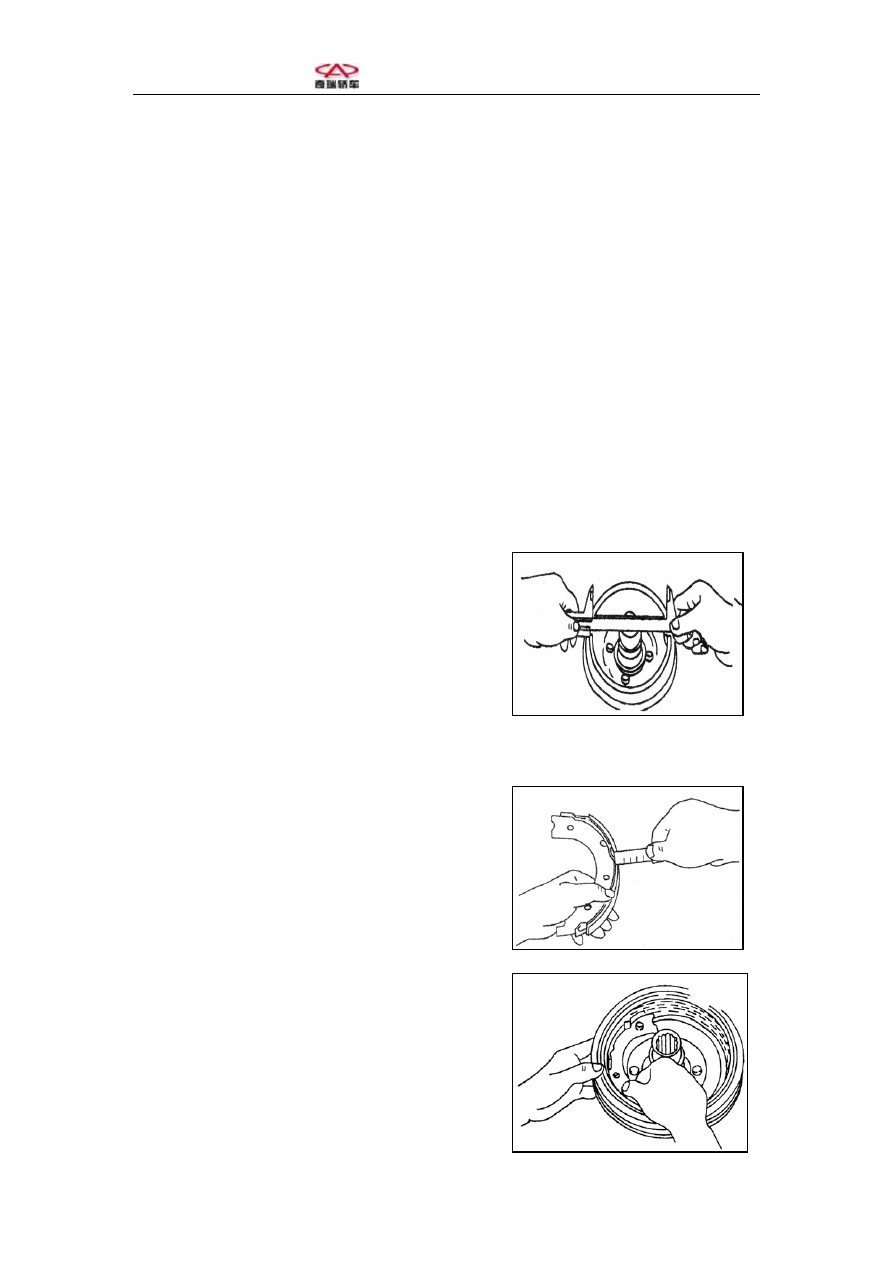

(1). Measure brake drum inner diameter as shown

in the figure.

Standard inner diameter: 200mm

Service limit: 201mm

In case scratches or slots occur on brake drum inner

diameter after use, reprocess it on a lathe.

Note: Do not exceed service limit when reprocessing with a lathe.

(2). Measure brake strip thickness as shown in

the figure.

Note: Service limit: 2mm

(3). Check the contact between brake strip and

brake drum as shown in the figure.