Chery A15. Manual - part 148

II. Filling Coolant

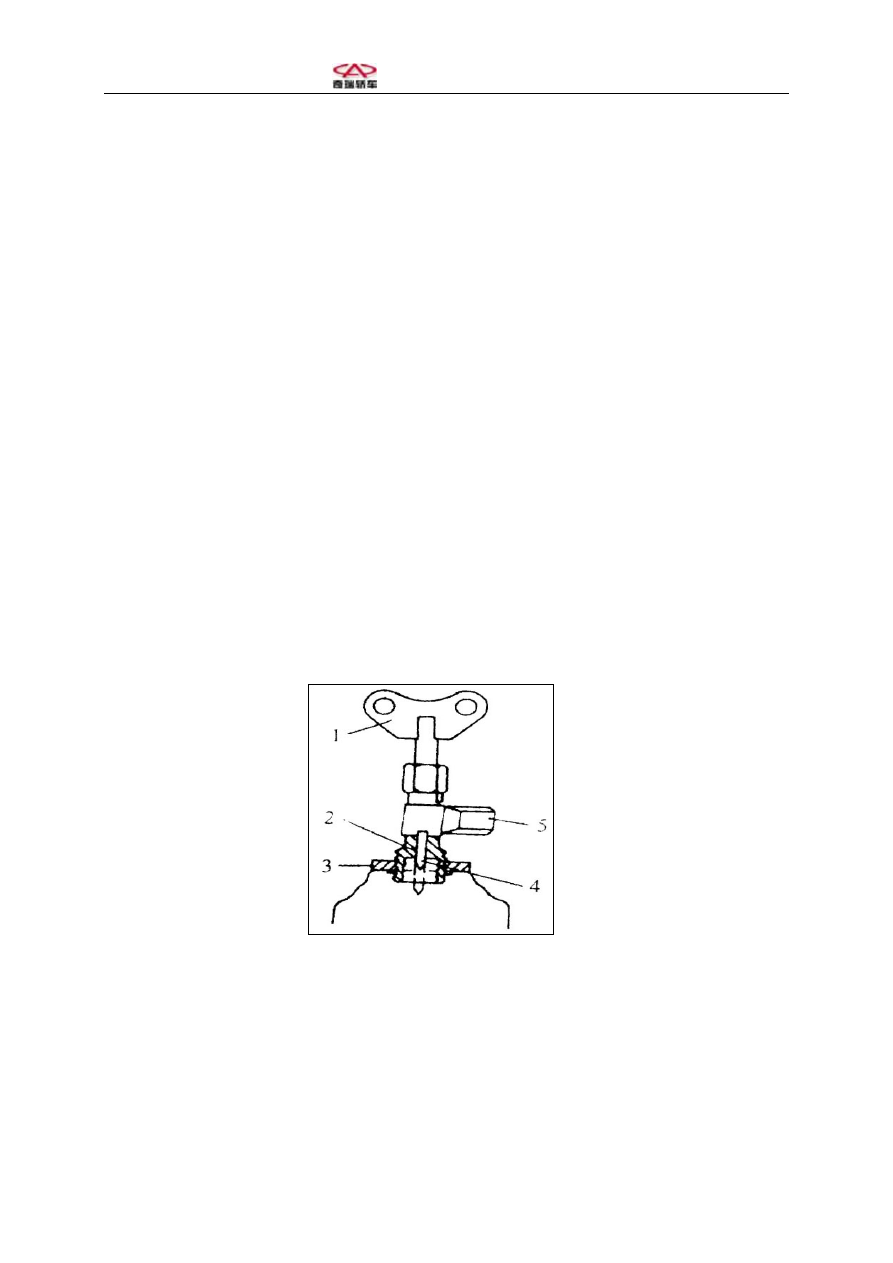

If a 400g coolant can is used, use coolant can opener (as the figure shows) to open the can in

the following steps:

(1) Counterclockwise turn the wing lever 1 before fiting the opener onto coolant can until

valve needle is retracted completely.

(2). Counterclockwise turn plate nut 3 then lift it to the highest position, and then tighten the

opener on the central bead of coolant can.

(3). Connect central filling hose of manifold pressure gauge with connector 5, and then

clockwise turn plate nut and tighten with hand.

(4). Clockwise turn wing lever 1 until valve needle 4 extrudes and penetrates a small hole in

coolant can bead.

(5). Counterclockwise turn wing lever 1, the coolant will flow into manifold pressure gauge

through filling hose.

(6) Clockwise turn wing lever 1 to the lowest position to reseal the coolant can. Do not

remove opener, otherwise coolant inside will leak out.

Coolant Can Opener

1-Wing lever 2-Filling valve 3-Plate nut

4-Valve needle 5-Filling valve connector

Coolant Filling Steps:

(1). Connect manifold pressure gauge and coolant can as shown in the figure.

(2). Counterclockwise turn lever of opener 2 to allow coolant enter central filling hose. Note