Chery A series. Manual - part 51

ASSEMBLY AND ADJUSTMENT OF CLUTCH CABLE

·Put dust cap up and screw jam nut (11) and

adjustment bushing (12) to the upper end

(make the adjustment travel L minimum)

so as to facilitate the assembly of clutch

cable.

·Coat a little lubricant on the assembly

fitting surface of clutch cable.

·Put clip (1) across the guiding cylinder of

clutch pedal on the front brattice to

connect the clutch pedal. Make sure that

washer (3) and end face of guiding

cylinder of clutch pedal are spliced.

·Make butt end (18) fixed by bracket after

across the slot in release arm of

transmission and rubber cushion through

the upper face of transmission.

·After the assembly, uplift the segregation

arm of transmission by hand and adjust the

adjustment bushing (12) down at the same

time, so the 2~3mm clearance for

segregation arm of transmission is

available; then tread the clutch pedal for 10

times to ensure the fitness of assembly and

readjust the adjustment bushing to

guarantee that the 2~3mm clearance for

segregation arm of transmission is

available (Remarks:For new clutch, the

adjustment travel L of driven disk cable

shall not be less than 18mm. See Pic.2).

·Carry out the driving examination for the

whole automobile. Clutch and gear shifting

operation shall be normal.

·Screw jam nut (11) down to close with

adjustment bushing (12), and then put

down dust cover (9).

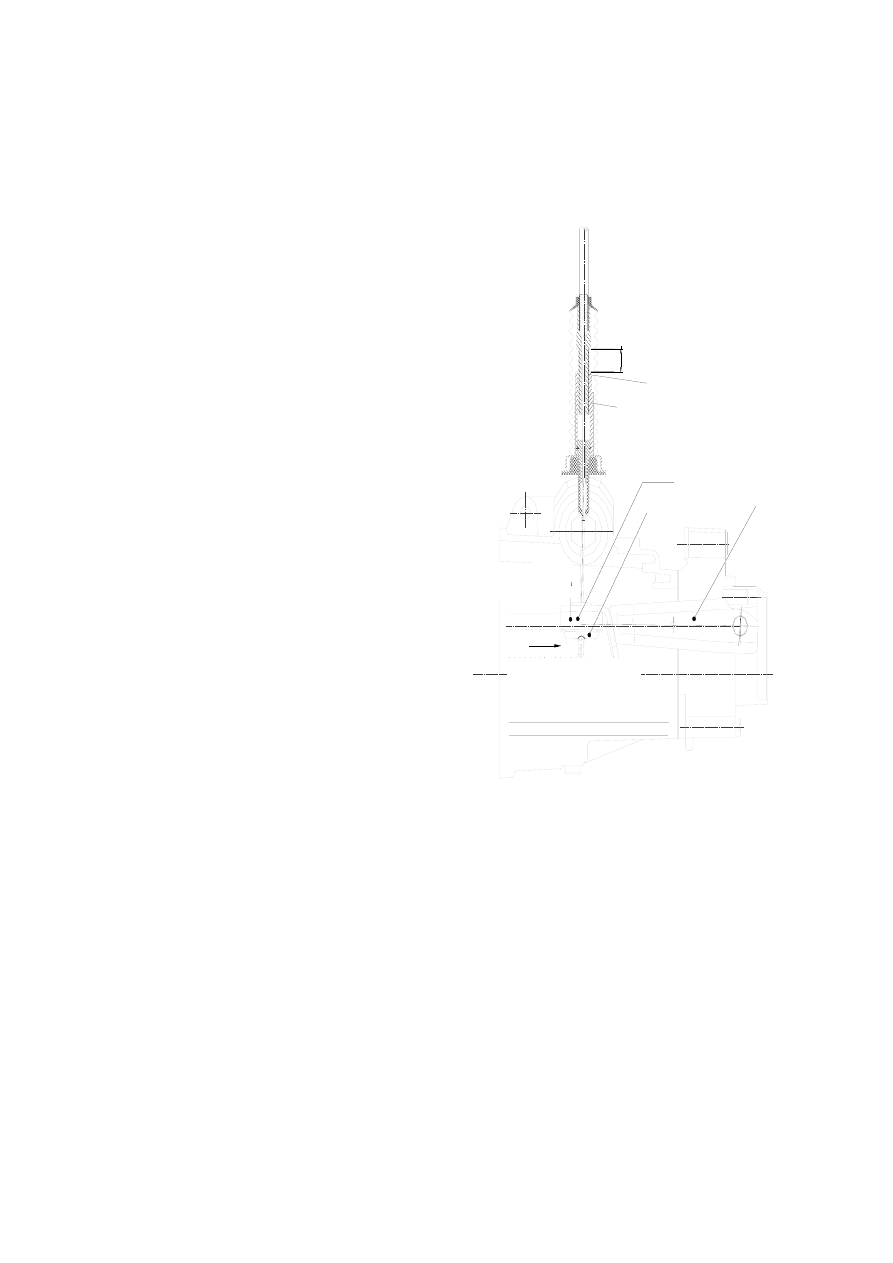

Picture 2 Sketch Map of Western

Clutch Adjustment

Move direction of release

disk after driven disk wear

down

Transmission

release pusher

When driven disk wear down,

unscrew the nuts and adjust the

bushing to a proper position

Adjust

bushing

Jam nut

Rubber cushion

Bracket

2~3mm free

travel

H-4

L (adjustment travel)