Lotus Eleven/Elise/Exige. Manual - part 36

Page 19

Lotus Service Notes

Section EH

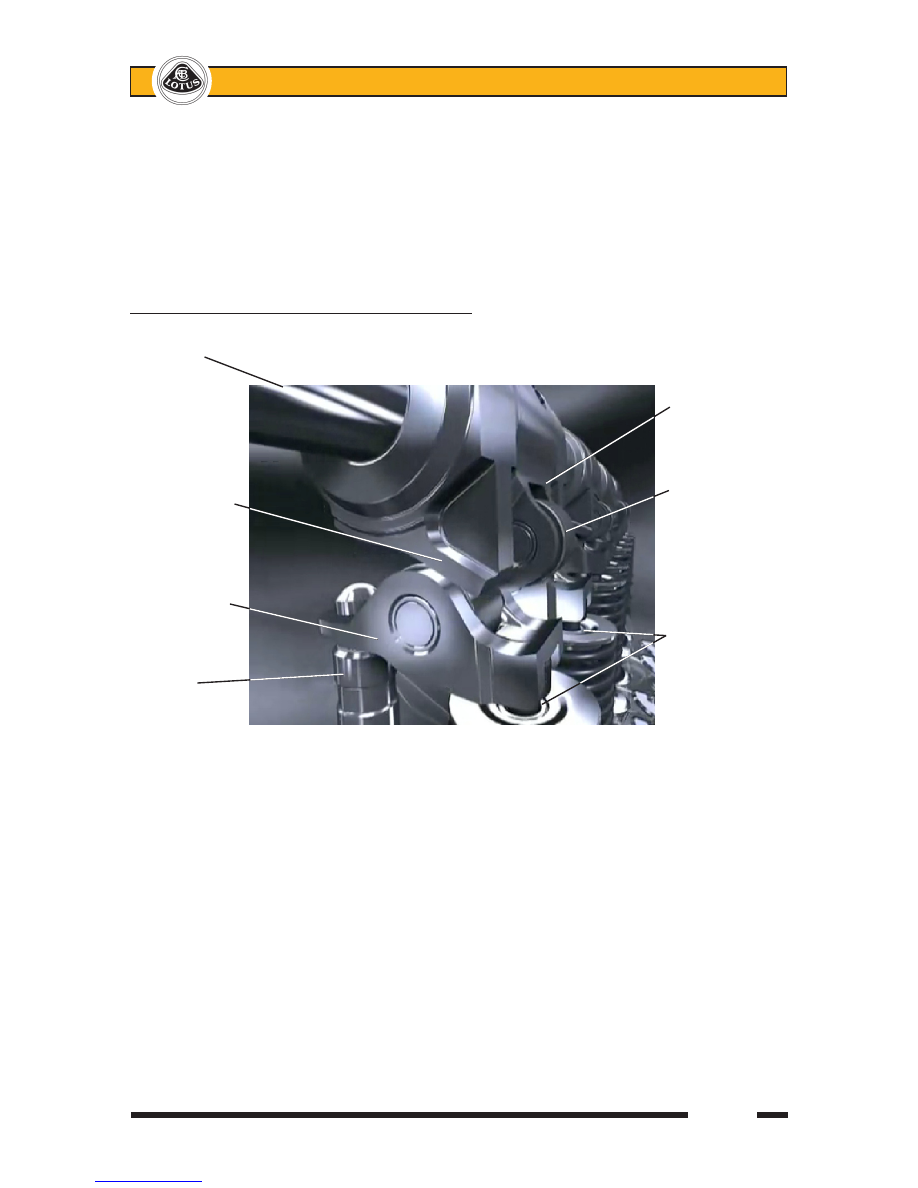

VALVEMATIC System

The principle of the VALVEMATIC system is that a conventional inlet camshaft with a single (rotary) cam

for each cylinder operates a roller arm on a pivot shaft. On each side of the roller arm is an oscillating cam,

each of which opens, via a finger follower, one of two conventional inlet valves for that cylinder. The two valves

are operated at all times as a pair. The connection between the roller arm and the two oscillating cams is made

via a common pivot sleeve machined with three separate sections of helical splines, which correspond with

splines in the bores of the roller arm and oscillating cams. By sliding the sleeve axially, within the roller arm

and cams, the opposite helix angle used for the cams compared with that for the roller arm, results in a phase

shift between arm and cams.

A 'lost motion' damper ensures that the roller arm stays in contact with the rotary cam profile at all times.

The position of the oscillating cams at the start of a valve opening event however, is dependent on their phasing

with the roller arm. In the low lift mode, where the cams are phased counterclockwise in relation to the roller

arm as viewed from the rear, the finger follower roller is in contact with the base circle of the oscillating cam,

which must turn through a large part of its range before the cam starts to lift the valve, resulting in only the first

portion of the cam profile being used. In high lift mode, the oscillating cams are phased clockwise in relation to

the roller arms such that the cam profile immediately starts to lift the valve as soon as the roller arm is depressed

by the rotary cam, continuing then to utilise the full profile of the oscillating cam for maximum lift.

The concomitant variation in valve timing as the lift changes, is managed by the separate VVT-i system

(see earlier).

Valves shown at full lift (camshaft omitted for clarity)

Pivot shaft

Roller arm

Camshaft

Oscillating cam operates against

this roller

Finger follower

Inlet valves

Hydraulic

pivot post