Haima M3. Chassis System. Service Manual - part 5

Brake system 2F-8

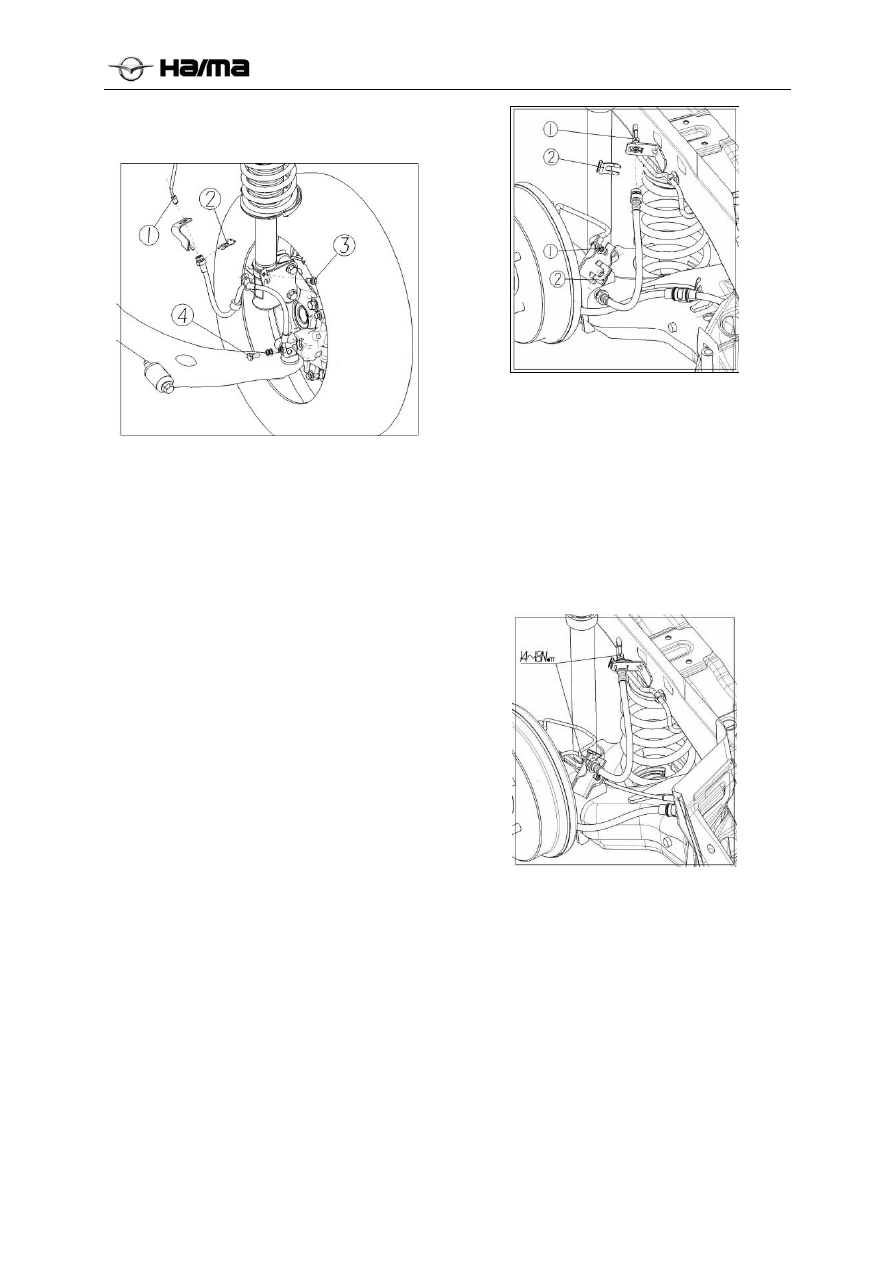

Repair instructions

(I) Repair on the vehicle

Front brake hose

Procedures for removing:

1. Remove the wheel.

2. Remove the brake hose.

●

Loosen the connector ① connected to brake

pipe.

●

Block the opening of brake pipe, and avoid

the loss and pollution of brake fluid.

●

Remove the snap spring ②.

●

Loosen the connecting bolt ③.

●

Remove the brake hose from the support.

●

Loosen the connecting bolt ④.

Installation procedures:

1. Connect the brake hose to pipe ①. Tightening

torque: 14 to 18N·m.

2. Install the snap spring ②.

3. Install the brake hose connecting bolt ④.

Tightening torque: 25. 5N·m.

Important: please apply the brake fluid

recommended by Sino Maersk Co., Ltd.

4. Exhaust the brake system. Refer to manual

exhaustion in this chapter.

5. Confirm whether the brake system is leaked.

6. Install the wheel.

Rear brake hose

Removal procedures:

①

Remove the wheel,

②

Remove the brake hose.

●

Loosen the connector connected to brake pipe

①

.

●

Remove the snap spring ②.

●

Block the opening of brake pipe, and avoid

the loss and pollution of brake fluid.

Installation procedures:

1. Connect the brake hose to the pipe.

Tightening torque: 14 to 18N·m (12 Ib-ft).

2. Install the snap spring.

Important: please apply only the recommended

brake fluid.

3. Exhaust the brake system. Refer to manual

exhaustion in this chapter.

4. Confirm whether the brake system is leaked.

5. Install the wheel.