Rover 214-414. Service Repair Manual - part 7

Torque wrench settings

Nm

lbf ft

Fuel system

Injector housing fuel pipe union nuts . . . . . . . . . . . . . . . . . . . . . . . . . . .

24

18

Injector housing fuel pipe adaptors . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24

18

Injector housing screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

4

Throttle housing retaining nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

13

Fuel system pressure release bolt - models without catalytic converter12 9

Fuel pump retaining nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

7

Vent valve and hose retaining nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

7

ECU retaining nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

7

Intake air temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

5

Coolant temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

11

Inlet manifold nuts and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

18

Inlet manifold support stay bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

18

Exhaust system

Oxygen (lambda) sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

55

41

Exhaust manifold retaining nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45

33

Exhaust manifold shroud screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

4

Exhaust system flange nuts:

Manifold-to-front pipe joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

37

All other joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45

33

Exhaust front pipe mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

11

4B•2 Fuel and exhaust systems - single-point fuel injection engines

1689 Rover 214 & 414 Updated Version 09/97

1

General information and

precautions

General information

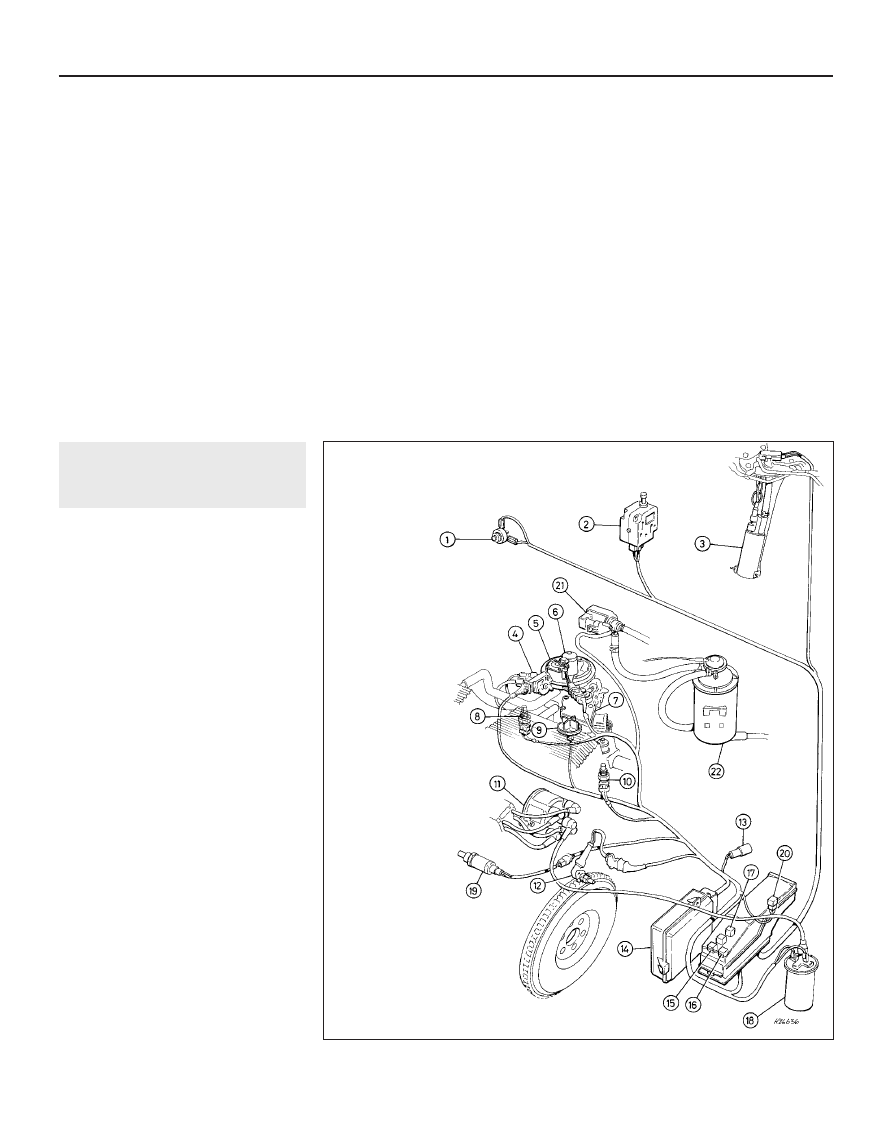

The fuel system consists of a fuel tank

mounted under the rear of the vehicle with an

electric fuel pump immersed in it, a fuel filter,

fuel feed and return lines and the throttle body

assembly (which incorporates the single fuel

injector and the fuel pressure regulator), as

well as the Engine Management Electronic

Control Unit (ECU) and the various sensors,

electrical components and related wiring. The

ECU fully controls both the ignition system

and the fuel injection system, integrating the

two in a complete engine management

system (see illustration). Refer to Chapter 5

for information on the ignition side of the

system.

The Rover/Motorola Modular Engine

Management System uses ECU-controlled

single-point injection (MEMS-SPi) and the

speed/density method of airflow

measurement. The whole system is best

explained if considered as three sub-systems

which are, the fuel delivery, air metering and

electrical control systems.

The fuel delivery system incorporates the

fuel tank with an electric fuel pump, which is

immersed in a swirl pot to prevent aeration of

the fuel, inside it. When the ignition is

switched on, the pump is supplied with

current via the fuel pump relay, under the

control of the ECU. The pump feeds petrol via

a non-return valve (to prevent fuel draining out

of the system components and back to the

tank when the pump is not working) to the fuel

filter and from the filter to the injector. Fuel

pressure is controlled by the pressure

regulator, which lifts to allow excess fuel to

1.0 Fuel and ignition system components - MEMS-SPi

1 Accelerator pedal

switch

2 Fuel cut-out inertia

switch

3 Fuel pump

4 Throttle

potentiometer

5 Fuel pressure

regulator

6 Injector

7 Stepper motor

8 Intake air temperature

sensor

9 Inlet manifold PTC

heater

10 Coolant

temperature

sensor

11 Distributor

12 Crankshaft sensor

13 Diagnostic connector

14 Engine management

ECU

15 Main relay

16 Fuel pump relay

17 Inlet manifold PTC

heater relay

18 Ignition HT coil

19 Lambda sensor -

models

equipped with

catalytic

converter

20 Lambda sensor relay -

models equipped with

catalytic converter

21 Purge valve (where

fitted)

22 Charcoal canister

(where fitted)