Rover 820, 825, 827. Repair Manual - part 2

Maintenance and servicing

1•5

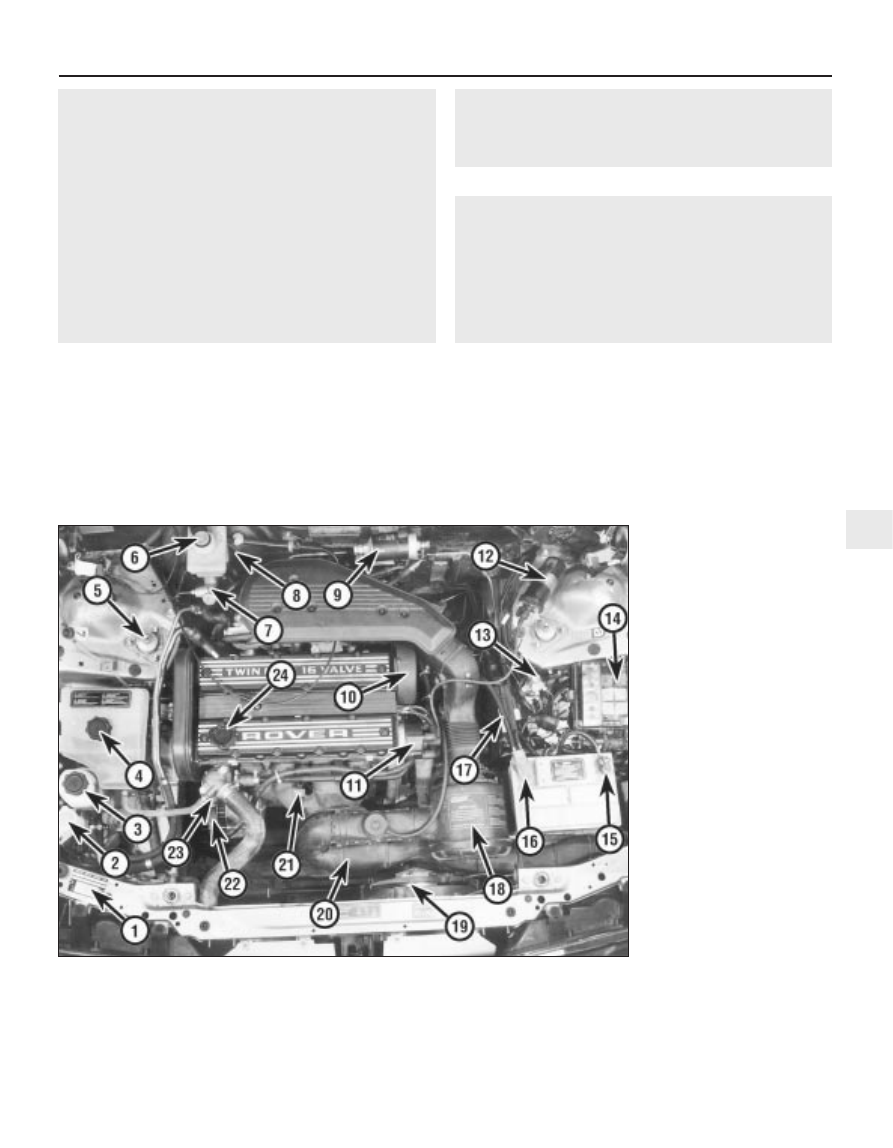

1 Vehicle identification plate

2 Screen washer reservoir filler

3 Power steering fluid reservoir

filler

4 Cooling system expansion tank

filler

5 Front shock absorber top

mounting

6 Brake and clutch fluid reservoir

filler

7 Brake master cylinder

8 Vacuum servo unit

9 Fuel filter

10 Power steering pump drivebelt

(early models)

11 Distributor cap

12 Ignition coil

13 Brake pressure reducing valve

14 Fuse and relay box

15 Battery negative terminal

16 Battery positive terminal

17 Ignition/fuel ECU

18 Air cleaner assembly

19 Radiator cooling fan

20 Air cleaner intake trunking

21 Engine oil dipstick

22 Alternator

23 Thermostat housing

24 Engine oil filler cap

1

1380 Rover 800 Series Remake

Every 24 000 miles (40 000 km) or

2 years, whichever occurs first

m

m

Renew the spark plugs (models with emission control

equipment) (Section 11).

m

m

Renew the air cleaner filter element (models with emission

control equipment) (Section 12).

m

m

Check the condition and tension of the timing belt

(Section 32).

m

m

Check the Positive Crankcase Ventilation system (Section 33).

m

m

Renew the fuel filter (Section 34).

m

m

Renew the automatic transmission fluid (Section 35).

m

m

Renew the brake fluid (Section 36).

m

m

Renew the manual transmission oil (Section 37).

m

m

Renew the coolant (Section 38).

Every 48 000 miles (80 000 km)

m

m

Renew the timing belt (Section 39).

Every 60 000 miles (100 000 km) or

5 years, whichever occurs first

m

m

Renew the braking system rubber seals (recommendation

only) (Section 40).

m

m

Check the operation of the emission control equipment

(Section 41).

Engine compartment component locations -

4-cylinder engine models with single-point fuel injection