Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 117

8-88

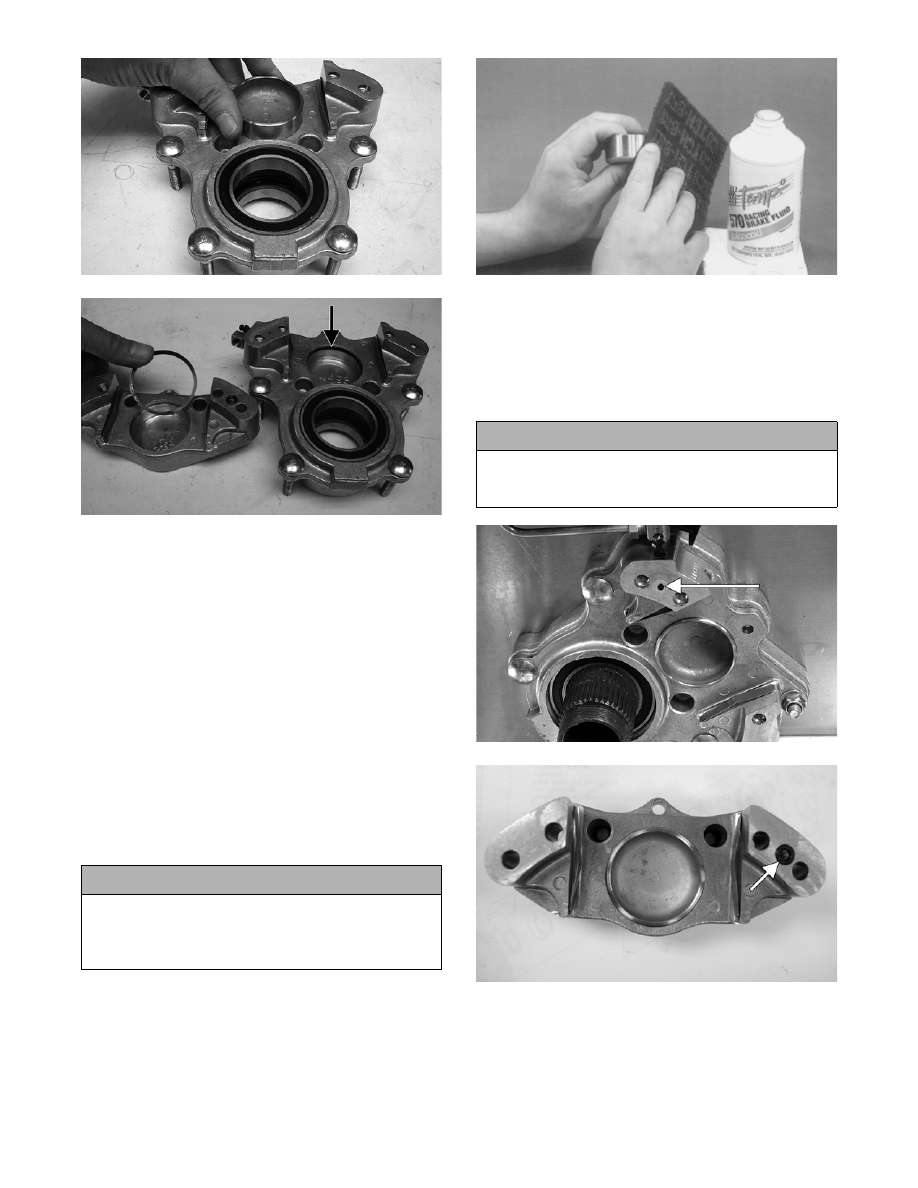

ZJ230

ZJ251A

Cleaning and Inspecting

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

1. Inspect the brake pistons for gouges, cracks, pit-

ting, scuffing, or corrosion. If any of these condi-

tions exist, replace the piston.

NOTE: The inner and outer caliper housings are

not serviceable components. If either or both are

defective or damaged, the complete caliper assem-

bly must be replaced.

2. Clean the piston outer surface by using a soft

Scotch-Brite pad and clean brake fluid as a

cleaner.

AF230

3. Inspect the piston bore of the inner and outer brake

calipers for gouges, cracks, pitting, scuffing, or

corrosion. If any of these conditions exist, replace

the caliper.

4. Clean the caliper inner wall surface using a soft

lint-free cloth and clean brake fluid.

ZJ225A

MS320A

5. Inspect the condition of the brake pads. Replace if

damaged or worn. The brake pad thickness must

be greater than 5.0 mm (0.020 in.). If the brake pad

thickness is less than specified, replacement of

both pads is necessary.

! CAUTION

Do not use any sharp cleaning tool on the piston

surface or in the O-ring groove as it may cause dam-

age. Parts-cleaning solvent must not be used as it

can damage the piston O-ring.

! CAUTION

Care must be taken not to allow any contaminants

into the fluid passages of the calipers or brake sys-

tem malfunction may occur.