Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 103

8-32

FS105

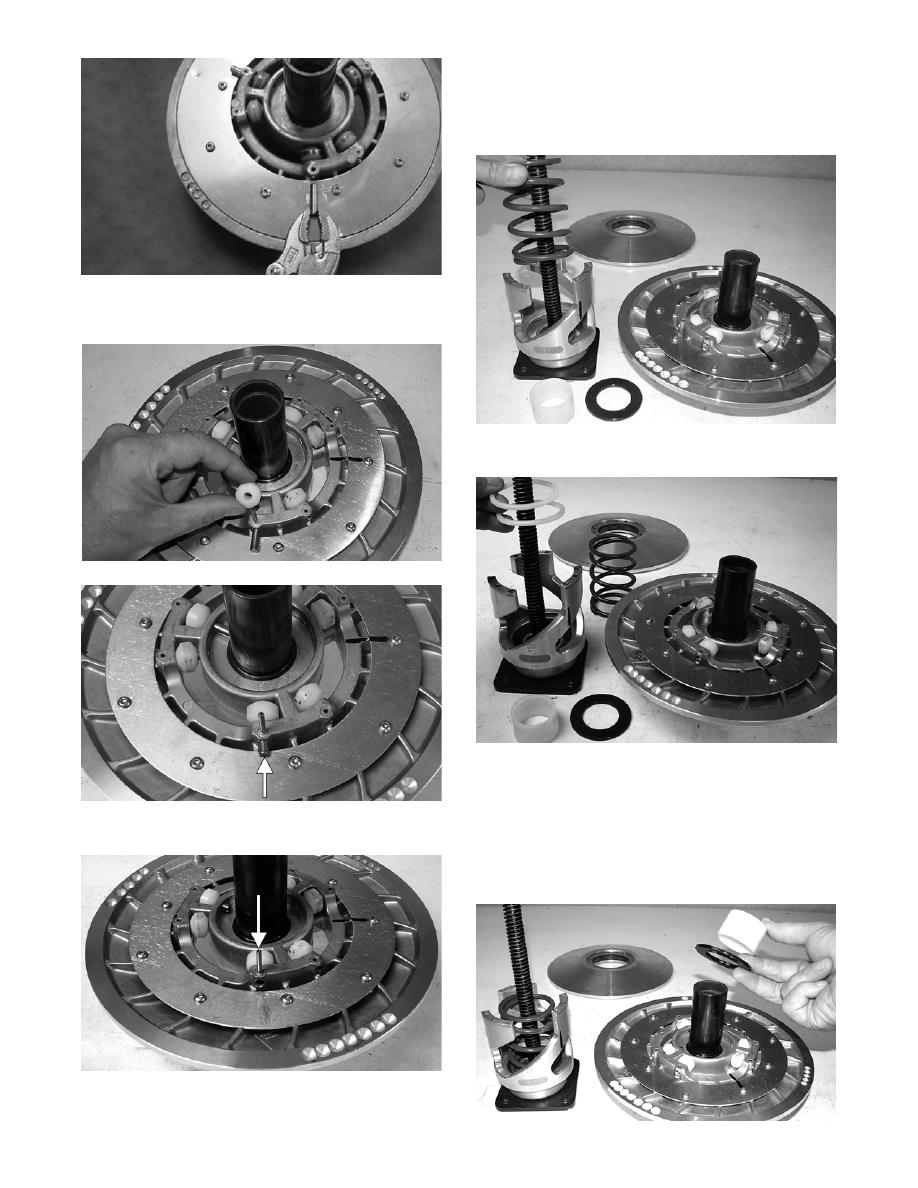

3. Place the new roller into position and tap the roller

pin in far enough to install the spring pin.

CM066

CM067A

4. Tap the spring pin back into place.

CM068A

ASSEMBLING

1. Place the torque bracket onto the Driven Pulley

Compressor (p/n 0644-444); then place the spring

and plastic washer (spring seat) into position.

CM063

2. Install the spring seats onto the torque bracket.

CM064

NOTE: Premature wear will result if the plastic

washer is not installed.

3. Noting the alignment marks made during disas-

sembling and with the spring seat and spacer on

the stationary sheave shaft, place the stationary

sheave onto the torque bracket.

CM062