Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 66

4-38

INSTALLING

1. In turn on each front union bolt, install a gasket,

check valve, and gasket; then install on the oil-

injection pump.

2. Place the gasket and oil-injection pump near the

engine; then install the lower union bolt through a

gasket, check valve, and gasket.

3. Position the oil-injection pump on the engine mak-

ing sure the oil-injection pump gear is correctly

aligned with the oil-injection pump drive gear.

4. Secure the pump with two screws, lock washers (if

applicable), and washers (if applicable). Tighten

screws to 1.1 kg-m (8 ft-lb).

5. Connect the two oil-delivery hoses to the adapter

plates. Secure with clamps.

6. Connect the oil-injection cable/control rod to the

pump and secure.

7. Connect the oil-supply hose to the oil-injection

pump inlet fitting. Secure with the clamp.

8. Bleed the oil-injection system (see Bleeding Oil-

Injection System in this sub-section).

9. Check the oil-injection system synchronization

(see Synchronizing Oil-Injection Pump in this sub-

section). Tighten the jam nuts securely.

NOTE: On EFI models to install the exhaust sys-

tem and the air silencer, see Section 2.

10. Install the carburetors/throttle bodies.

11. On carbureted models, turn the shut-off valve to

the OPEN position.

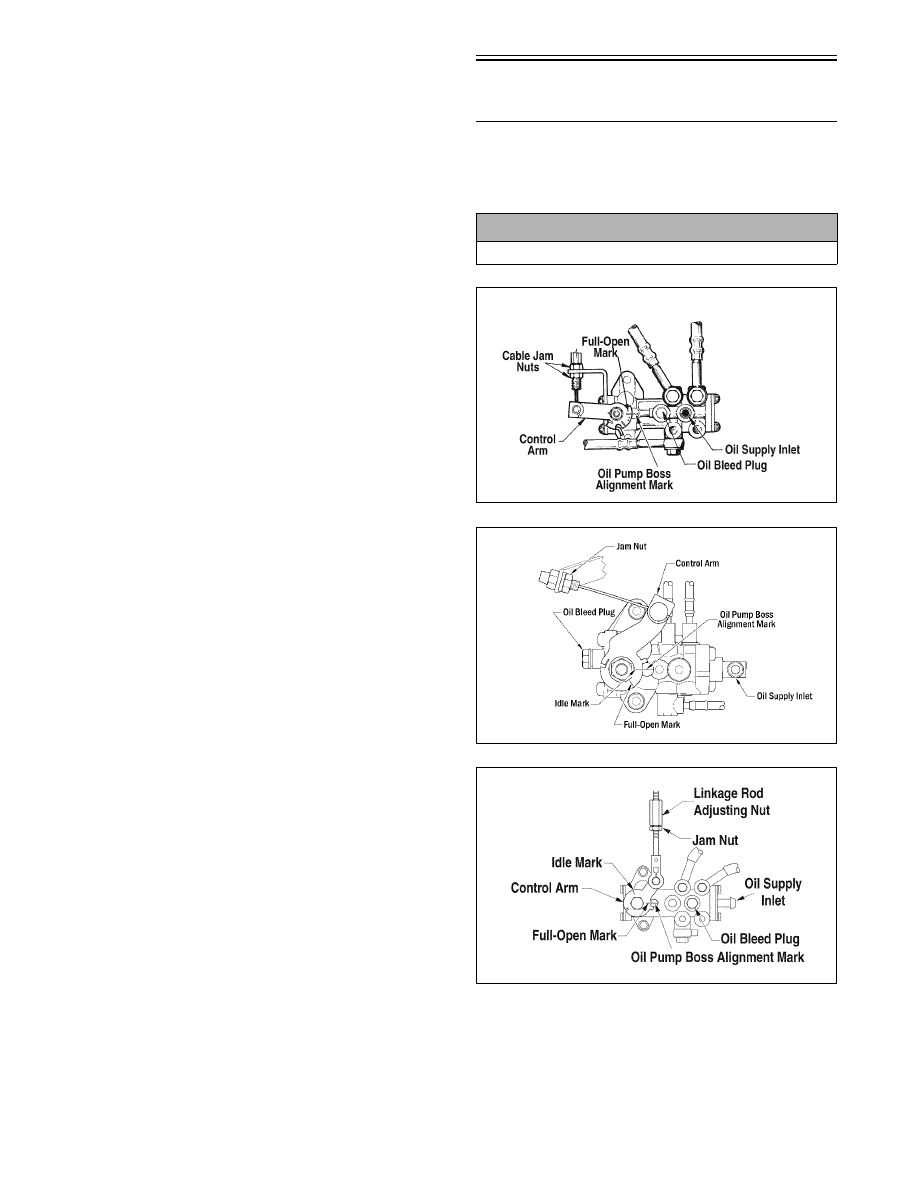

Synchronizing

Oil-Injection Pump

NOTE: On certain models, the oil pump cable

adjuster is located at the juncture of the throttle

cable.

728-713A

742-331A

738-338C

! CAUTION

Use a 100:1 fuel mixture for the following procedure.

370/570 cc

500 cc

600 cc