Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 20

2-66

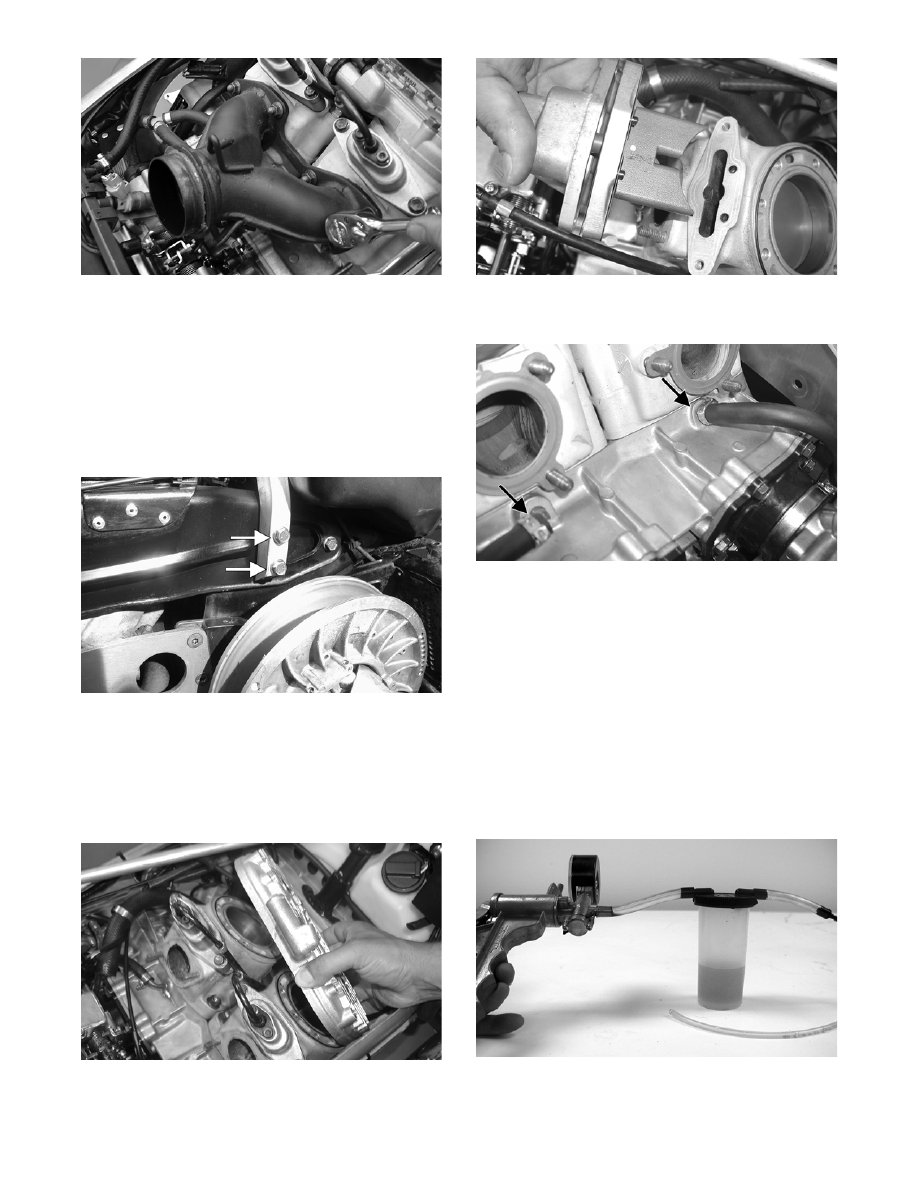

CM035

2. Drain the engine coolant (see Liquid Cooling Sys-

tem - Section 3).

3. Remove the cap screws and the lock nuts securing

the side-plate brace to the chassis; then remove the

brace.

NOTE: The cap screws securing the steering

support to the chassis must be removed to remove

the side-plate brace.

CM004B

4. Remove the coolant hose and breather hose con-

nected to the cylinder head.

5. Remove the twelve 10 mm cap screws and two 8

mm cap screws (500 cc) securing the cylinder

head; then remove the cylinder head. Account for

the O-rings.

FC060

6. On the 600 cc, remove the APV’s from the cylin-

der.

FC056

7. Disconnect the two coolant hoses located beneath

the exhaust ports on the cylinders.

FC050A

NOTE: At this point, remove all loose hardware to

avoid any falling down into the chassis.

8. Remove the residual coolant from the cylinder/

crankcase water jacket.

NOTE: After draining the coolant, approximately

1.75 fluid oz of coolant will remain on both the

MAG-side and PTO-side. To remove the residual

coolant, use the following procedure.

a. Using Vacuum Pump (p/n 0644-131), or a suit-

able substitute, rig the pump to 3/16 in. outside

diameter hose.

FC058

b. In turn on each fitting of the crankcase, run the

vacuum pump to purge the cylinder/crankcase

water jacket of the residual coolant.