Snowmobile Arctic Cat (2004 year). Manual - part 110

8-40

AF433

NOTE: If the chain is too tight and wont allow the

top sprocket to be removed, remove the PTO-side

driven shaft bearing. This will allow the driven

shaft to be lifted at the PTO-side and will loosen

the chain.

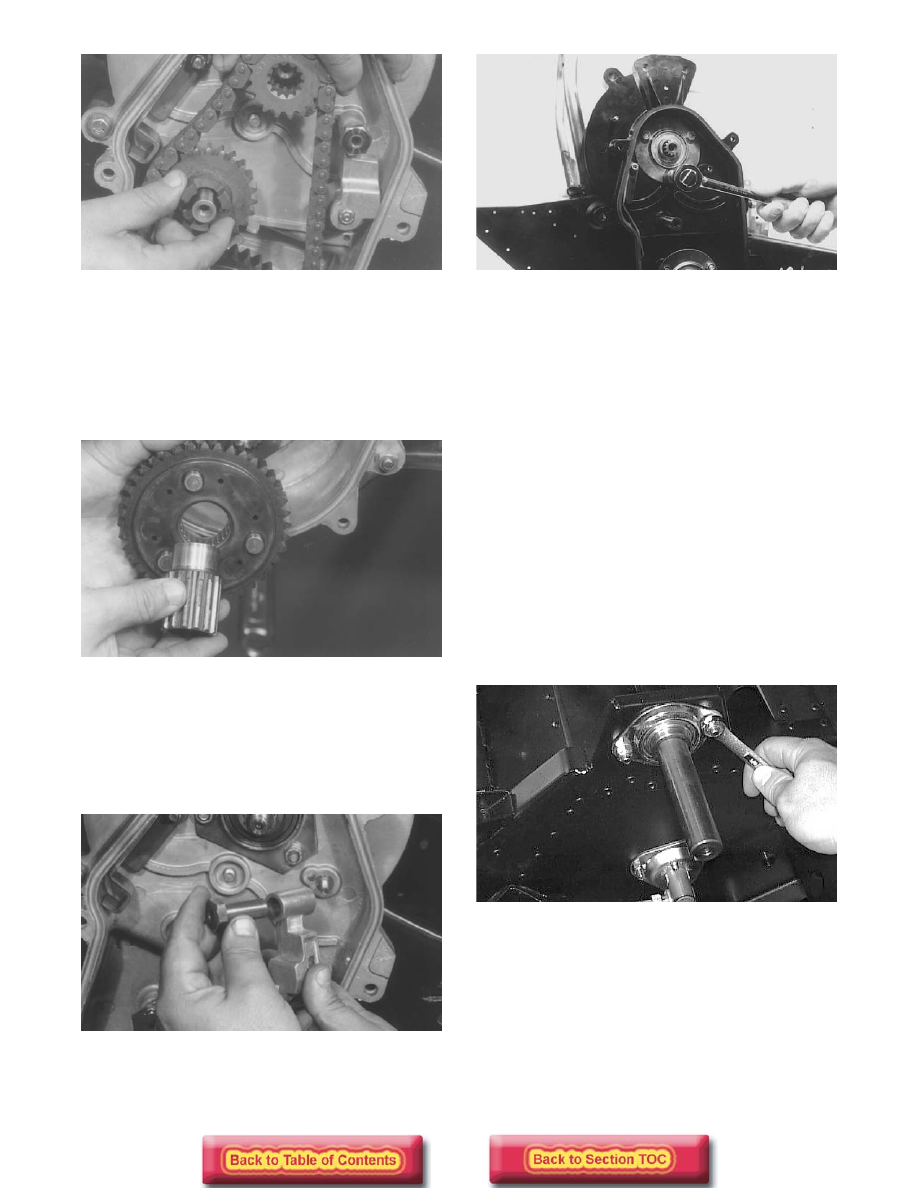

18. Remove the driveshaft extension, bottom sprocket,

and spacer washer.

AF427

19. Check the idler gear shaft. If the shaft surface is

rough, remove the shaft using a pair of vise-grip

pliers. Rotate the shaft counterclockwise.

20. Remove the shoulder nut securing the chain

tightener arm; then remove the arm from the chain

case.

AF447

21. Remove the three lock nuts securing the top

bearing flange plate. Remove the flange plate,

seal, and bearing.

AI018

22. Remove the three lock nuts securing the bottom

bearing flange plate. Remove the flange plate,

seal, and bearing.

NOTE: Steps 23-27 are for standard models.

23. Remove the screw securing the air-intake silencer

to the steering support; then pull the silencer

forward and place it on the carburetor/throttle

body assembly.

NOTE: Using a hold-down strap, secure the air-

intake silencer to the engine.

24. Loosen the set screw on the PTO-side driven shaft

collar. Drive the collar clockwise (opposite shaft

rotation) until it is free.

NOTE: A fine file should be used to remove any

burrs left by the collar set screw.

25. Remove the lock nuts and carriage bolts securing

the PTO-side driven shaft flange plates.

AF002D

26. Force the driven shaft toward the PTO-side

(rotating the shaft to prevent the brake disc from

binding on the shaft) until brake disc is free.

Account for the key.

27. Continue to slide the driven shaft until it is out of

the PTO-side. Account for a bearing, two flange

plates, and the PTO-side driven shaft collar.

NOTE: Steps 28-31 are for AWS VI models.