Snowmobile Arctic Cat (2004 year). Manual - part 103

8-12

Drive Train and

Brake Systems

This section has been organized into sub-sections for

servicing drive train and brake systems; however,

some components may vary from model to model. The

technician should use discretion and sound judgment

when removing and installing components.

NOTE: Some illustrations and photographs used

in this section are used for clarity purposes only

and are not designed to depict actual conditions.

Drive Belt

The belt dimensions and construction are two factors

that influence the performance of the drive system.

The two belt dimensions that are important to the per-

formance of the snowmobile are the outside circumfer-

ence and the width. Both of these dimensions will

influence shifting characteristics.

If the drive belt is longer than specified, the drive

clutch and driven pulley will not have the full shift

ratio. Also, a too-long drive belt will cause poor accel-

eration and a decrease in top speed.

If the drive belt is shorter than specified, the drive

clutch and driven pulley will have a different shift pat-

tern because they are in different ratios from those for

which they were originally matched. A too-short drive

belt will cause a loss in performance and a bog on

engagement.

NOTE: A drive belt that is worn thin may produce

the same effect as one that is too long.

Drive belt construction has an influence on the way the

drive clutch and driven pulley will shift and on the

amount of power that will be transmitted through the

system. ONLY ARCTIC CAT DRIVE BELTS

SHOULD BE USED. Different brands of belts may

not have the same construction causing either more

friction or more slippage when the belt is wedged

between the sheaves and, thus, a loss of efficiency.

NOTE: A stiff belt causes a HP loss to the track.

As a belt warms up, it gets more flexible and trans-

mits power with less HP loss.

Drive Clutch

CHANGING CAM ARMS (9-Post Style)

The cam arms on the drive clutch can be changed

without disassembling the clutch. To change the cam

arms, use the following procedure.

1. Check to make sure the ignition switch is in the

OFF position.

2. Remove the drive belt.

3. Compress the movable sheave approximately 2.5

cm (1 in.) and while holding it in this position,

insert a flat bar firmly between the bottom side of

the spider and the inner surface of the movable

sheave. Slowly release the movable sheave.

4. Remove the lock nuts from the three cam arm

pins.

5. Remove the cam arm pins one at a time; then

remove the cam arm with bushing and account for

the washers.

NOTE: When installing cam arms, always use

new lock nuts. Make sure the head of each cam

arm pin is positioned towards the direction of

drive clutch rotation. Tighten nuts until they con-

tact the shoulder of the cam arm pin; then tighten

an additional 1/8 turn.

733-452B

6. Change the cam arms and secure with new lock

nuts and existing pins making sure the head of

each pin is positioned toward the direction of drive

clutch rotation.

NOTE: The drive clutch rotates counterclock-

wise.

CHANGING CAM ARMS (6-Post Style)

The cam arms on the drive clutch can be changed

without disassembling the clutch. To change the cam

arms, use the following procedure.

! WARNING

Do not run the engine with the drive belt removed

or the bar in the clutch.

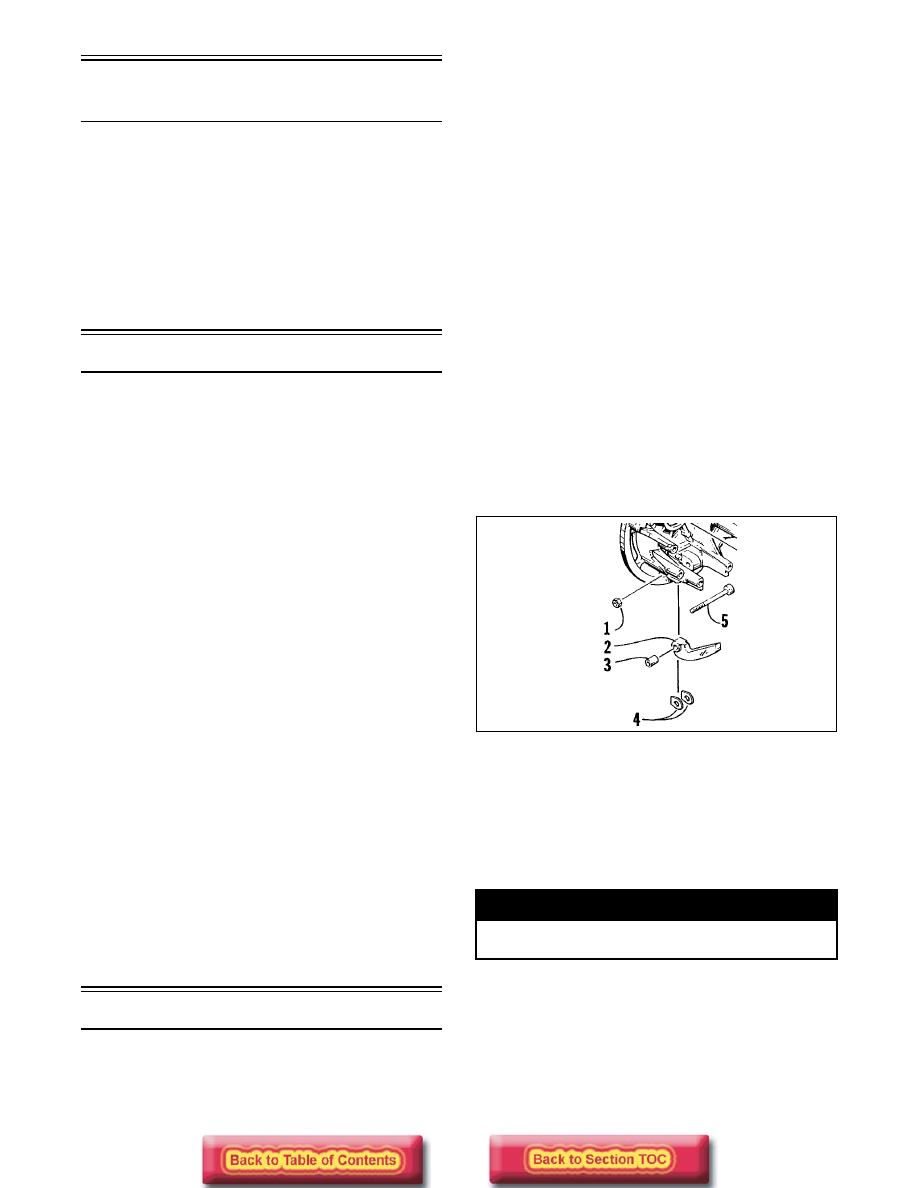

KEY

1. Lock Nut

2. Cam Arm

3. Bushing

4. Washer

5. Pin