Snowmobile Arctic Cat (2002 year). Manual - part 177

9-186

Bearing Cap

and Shaft Seal

REMOVING AND DISASSEMBLING

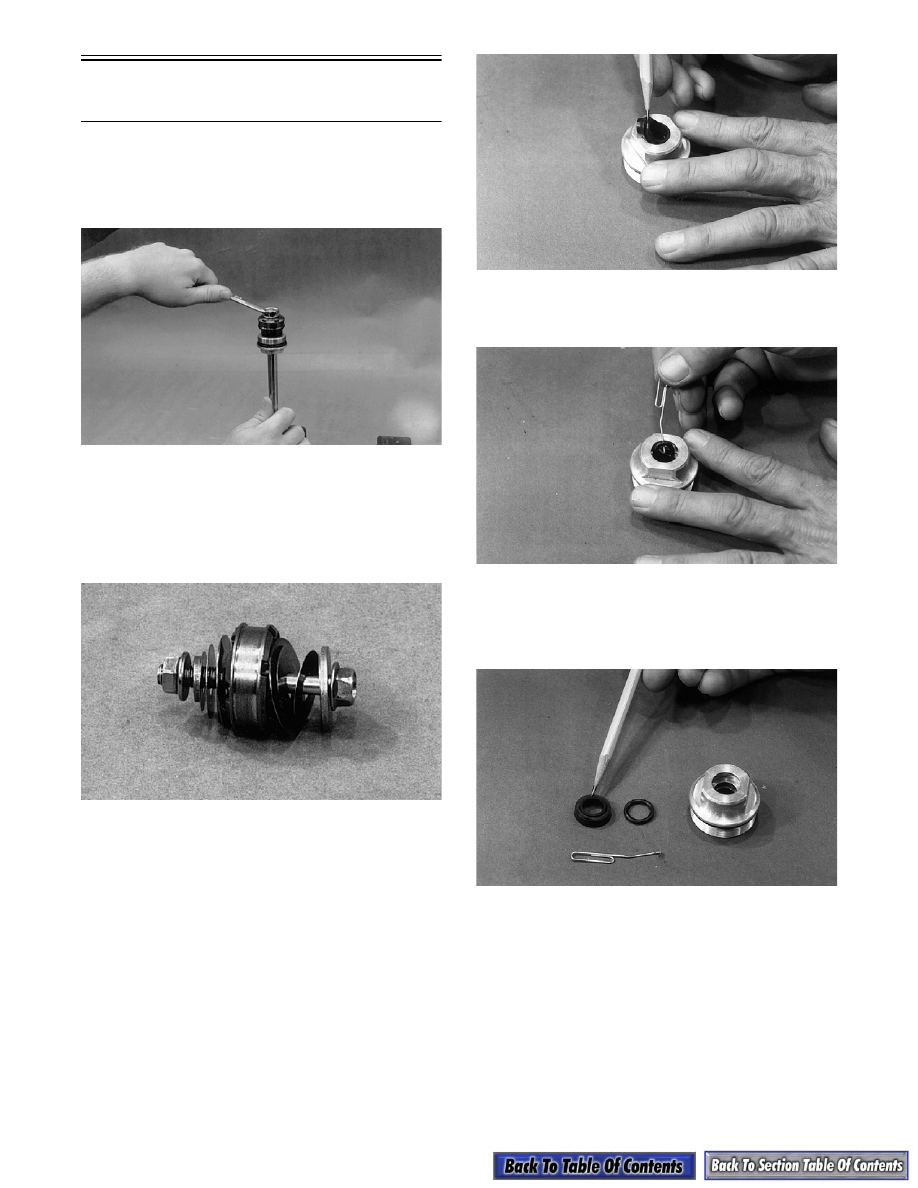

1. With shaft assembly removed from shock body,

clamp shaft eyelet in vise and remove the lock nut.

AP028

2. Lift the piston valve assembly.

NOTE: When removing the piston and valve

plates from the shock shaft, place the piston

assembly on a 5/16 x 3-in. cap screw and secure

with a nut to keep the assembly in its proper order.

AP032

3. Remove the bearing cap (on front arm adjuster

shocks, remove the adjuster piston and a spacer

washer first).

4. Remove the outer plastic wiper; then remove the

inner rubber wiper from the bearing cap.

AG257

5. Using a small paper clip bent on one end, remove

the inner O-ring.

AG258

ASSEMBLING AND INSTALLING

1. Install new O-ring and inner rubber wiper into the

shaft bearing cap; then install outer plastic wiper.

AG259

2. Inspect the shoulder or step of the shaft for sharp

edges or a burr. Smooth up with #400 grit sand

paper or emery cloth.

3. Put Bearing Cap Installation Tool (p/n 0644-268)

over the threaded end of the shaft.