Snowmobile Arctic Cat (2002 year). Manual - part 119

8-34

SC013D

32. Check the alignment of the drive clutch/driven

pulley (see Drive Clutch/Driven Pulley in this

section).

33. Assure that the chain case drain plug is tightened

to 4.8 kg-m (35 ft-lb); then pour 354 ml (12 fl oz)

of Arctic Cat Transmission Lube (p/n 0636-817)

into the chain case.

34. Install the drive belt and check belt deflection.

Secure the belt guard.

35. Install and secure the battery tray and battery; then

connect the battery cables making sure to connect

the positive cable first.

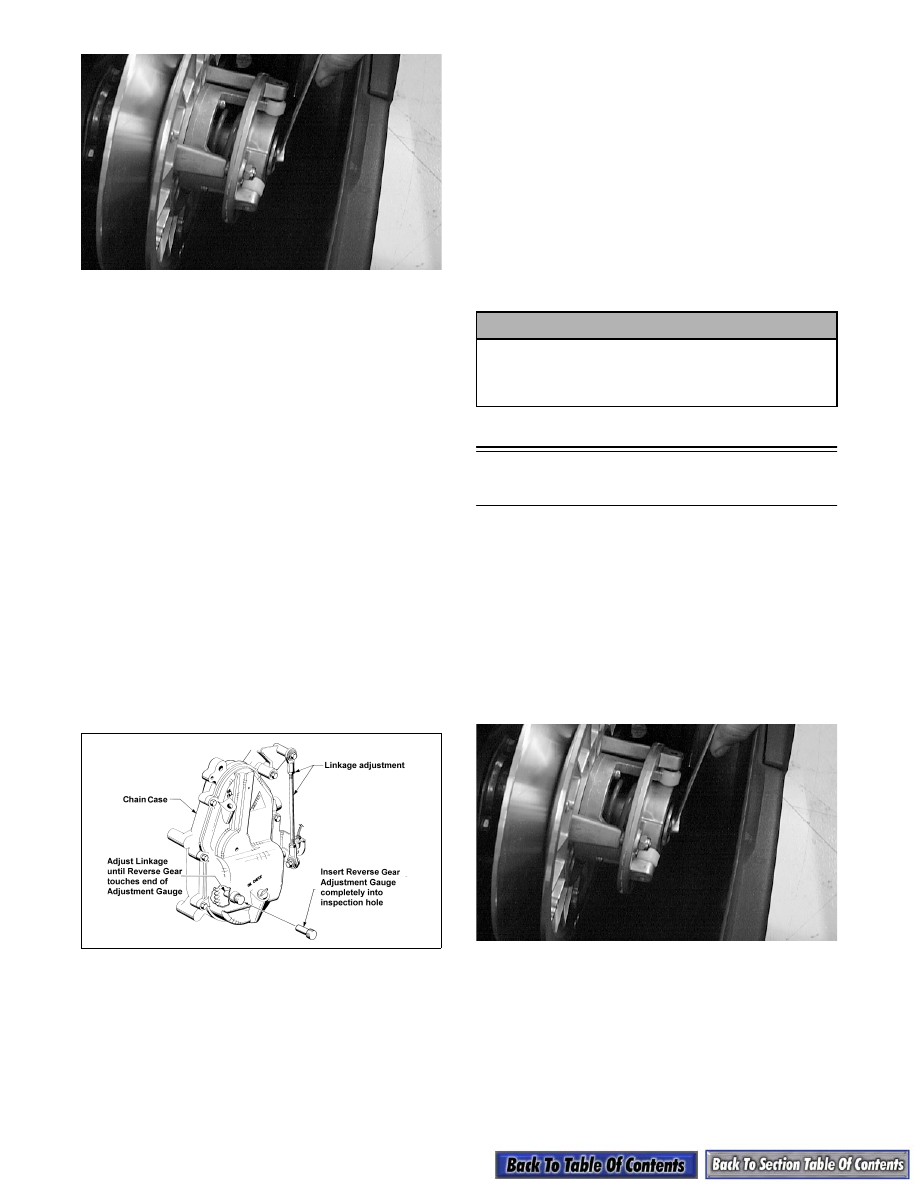

ADJUSTING REVERSE LINKAGE

1. Start the engine; then test the shifting

characteristics of the reverse transmission.

2. If adjustment of the reverse gear is necessary, stop

the engine and remove the chain case inspection

plug located behind the oil level stick; then insert

the Reverse Gear Adjustment Gauge (p/n 0644-

244) completely into the inspection hole.

0731-734

3. Pull the shift lever into the reverse position while

holding the adjustment gauge firmly against the

chain case cover. Slight outward pressure should

be felt on the gauge as the lever locks into reverse.

4. If no contact is noted, loosen the jam nuts securing

the lower shift linkage and adjust the linkage rod

until the gauge is pushed out of the chain case

0.254-0.381 mm (0.010-0.015 in.). Lock the

adjustment by tightening the jam nuts securely

against the tie rod ends.

NOTE: To adjust the linkage rod, the shift lever

must be moved to the forward position.

5. Install the inspection plug.

6. Start the engine; then test the shifting

characteristics of the reverse transmission. Adjust

as necessary.

Drive Train/Brake Disc

(w/o Reverse)

DISASSEMBLING

1. Remove the chain-case drain plug (located on the

lower back side of the chain case inside the tunnel)

and drain the chain case lubricant.

2. Open the belt guard and remove the drive belt.

3. Remove the cap screw and washer securing the

driven pulley; then account for and note the

position of any alignment washers.

SC013D

4. Slide the driven pulley off the driven shaft; then

remove the driven pulley from the engine

compartment. Account for the stub shaft, key, and

alignment washers.

NOTE: If the driven pulley is tight on the driven

shaft, pull the driven pulley off using the Driven

Pulley Puller (p/n 0744-023).

! CAUTION

The linkage must be properly adjusted. If the

linkage is too short, damage to the shift fork may

occur. If the linkage is adjusted too long, the

gears will not shift totally into reverse.