Snowmobile Arctic Cat (2002 year). Manual - part 81

5-43

5

0725-653

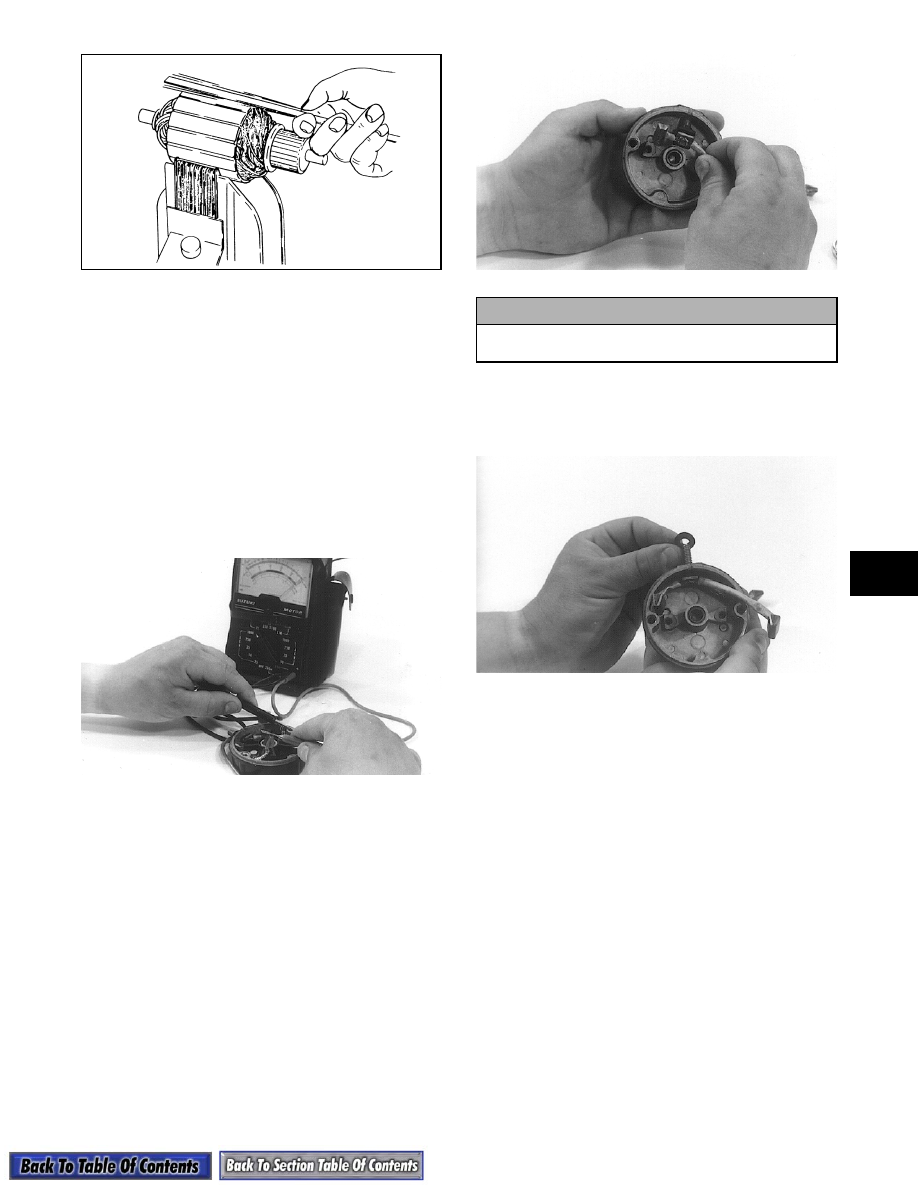

11. Inspect the ground brushes to make sure they are

properly grounded. Use the multitester and the

following procedure:

A. Set the selector on the X1K position; then touch

the leads and zero the meter.

B. Touch the black tester lead to a ground brush.

C. Touch the red tester lead to the commutator

cap. The meter needle should move to the right.

If the needle does not move to the right, check

that the ground connection is tight and clean.

Recheck for proper ground. If there still isn't

any meter needle movement, replace the

brushes as a set along with new brush springs.

AI035

ASSEMBLING

1. Install the stud with the positive brush set attached

in the commutator cap. Make sure the insulator is

in position over the stud and the longest brush lead

is positioned to the right of the stud hole.

AI038

2. In order from disassembling, place the washers on

the stud. Apply a small amount of red Loctite #271

to the stud threads and secure with the nut. Tighten

to 0.7 kg-m (5 ft-lb).

AI039

3. Place the brush holder into position in the

commutator cap.

NOTE: Position the longest positive brush lead

beneath the ground wire on right side.

4. Place a cap screw through the left ground brush

lead eyelet and position the eyelet flat against the

brush holder. Secure with a cap screw.

5. Place the right ground brush eyelet flat against the

brush holder and secure with a cap screw. The

eyelet stem must be positioned to the top of the

threaded hole boss in the commutator cap.

! CAUTION

Check the stud to make sure insulator is

between stud and cap on backside.