Snowmobile Arctic Cat (2002 year). Manual - part 64

4-49

4

AO145D

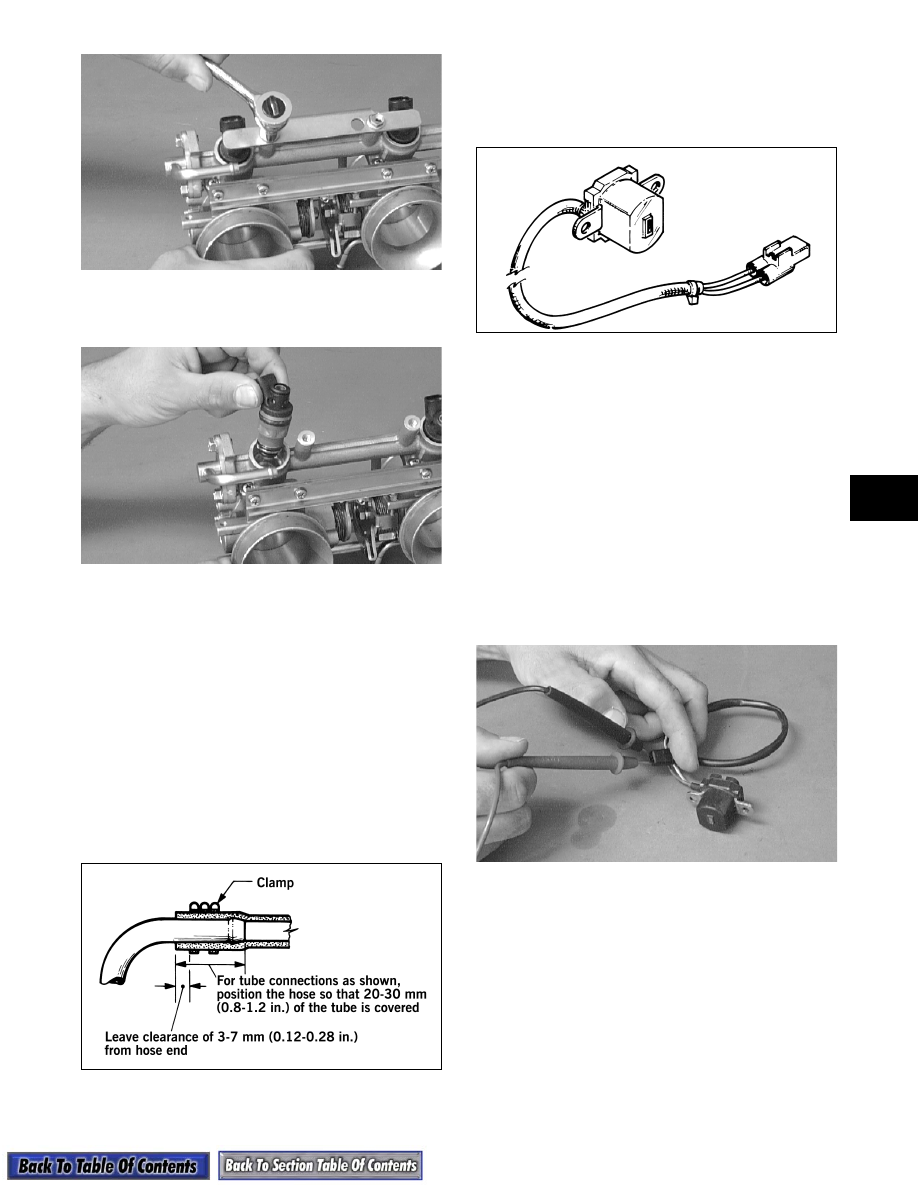

4. Remove the fuel injectors from the throttle body

assembly.

AO146D

Installing

1. Apply a light coat of oil to all O-rings; then install

the upper and lower O-rings onto each injector.

2. Install the injectors into the throttle body

assembly.

3. Place the injector hold-down plate into position on

top of the injectors and secure with two screws.

4. Connect the fuel delivery hose to the fuel rail and

secure with a clamp.

NOTE: When securing the fuel delivery hose,

position the clamp as shown.

0729-325

5. Connect the wiring harness to the injectors making

sure the number 1 harness is connected to the

MAG-side injector.

IGNITION TIMING SENSOR

0729-627

NOTE: This sensor is located on the top of the

magneto case on some models. On other models

the sensor is located inside the magneto case next

to the flywheel, and on these models, the recoil

starter and the flywheel must be removed to

access the sensor.

Testing Resistance

1. Disconnect the two leads from the sensor to the

main wiring harness.

2. Set the meter selector to the OHMS scale.

3. Test between the green/white and brown leads

from the sensor. Test specification is 152-228

ohms.

AO147D

Removing

1. Open the rubber boot that protects the main wiring

harness connections; then disconnect the ignition

timing sensor from the ECU wiring harness.

2. Remove the two screws securing the sensor to the

magneto housing.

3. Remove the sensor.