Snowmobile Arctic Cat (2002 year). Manual - part 63

4-45

4

AO138DA

FUEL PRESSURE REGULATOR

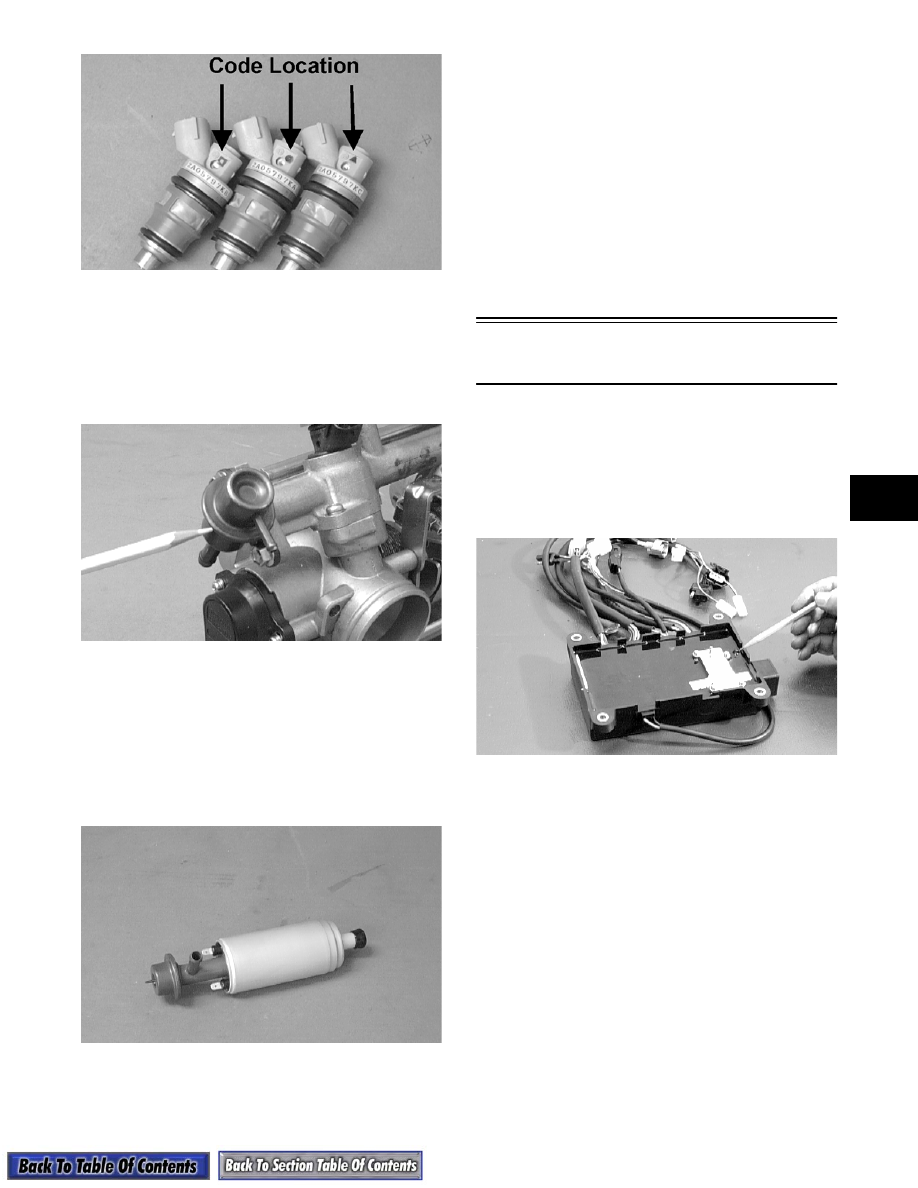

The fuel pressure regulator is attached to the end of the

fuel rail (600 cc) and in the fuel pump (800 cc). The

fuel pressure regulator maintains the fuel pressure at a

constant level of 37.9 ± 2.2 psi (600 cc) or 48 ± 2.2 psi

(800 cc).

AO141D

On the 600 cc when fuel pressure exceeds the specifi-

cation, the spring-loaded diaphragm in the regulator

opens allowing fuel to flow through the return hose

back to the gas tank.

FUEL PUMP CIRCUIT

The fuel pump and its circuit are provided with current

from the fuel pump coil on the stator.

AO142D

For this circuit to function correctly, five components

must be in good working order.

Check the following components before considering

the fuel pump assembly to be defective.

A. Fuel pump coil - see coil test procedure.

B. Emergency stop switch and ignition switch

must be ON and in good working order.

C. Fuel pump - see fuel pump test procedure.

D. Wiring harness and connectors - clean the

connectors and test the harness.

E. ECU.

Self-Diagnostic

EFI System

INTRODUCTION

The Electronic Control Unit (ECU) contains a built-in,

self-diagnostic system which detects trouble within the

five-sensor signal network and then flashes a code on

the LED signal light, located under the left end of the

ECU.

AO153D

The fuel system and the ignition system remain two

separate systems. In a no-start situation, first deter-

mine if the problem is caused by lack of spark or by a

fuel delivery problem.

Using the EFI Ignition Analyzer, equipped with the

update EPROM (chip) and test harness, connect the

test harness to the ECU diagnostic connectors. Con-

nect the test harness red external lead to the positive

terminal of a 12-volt battery and connect the black

external test harness lead to the negative terminal.

If any of the circuits are faulty, a trouble code will now

be flashed by the LED.

If no code is flashed, turn on the analyzer. Press the

MENU SELECT buttons until the words KOKUSAN

appear on the display; then press the TEST button. The

analyzer is now programmed for testing the Arctic Cat

Batteryless EFI System.