Snowmobile Yamaha Phazer PZ50W, PZ50GTW, PZ50FXW, PZ50MW, PZ50VTW, PZ50MPW. Manual - part 4

2-4

INSP

ADJ

SPARK PLUGS/FUEL LINE INSPECTION

ENGINE

SPARK PLUGS

1. Remove:

• Fuel tank

Refer to “SEAT AND FUEL TANK” in CHAP-

TER 5. (PZ50/PZ50GT/PZ50FX/PZ50M)

Refer to “RIDER SEAT AND FUEL TANK” in

CHAPTER 5. (PZ50VT/PZ50MP)

2. Remove:

• Spark plug caps

• Spark plugs

3. Inspect:

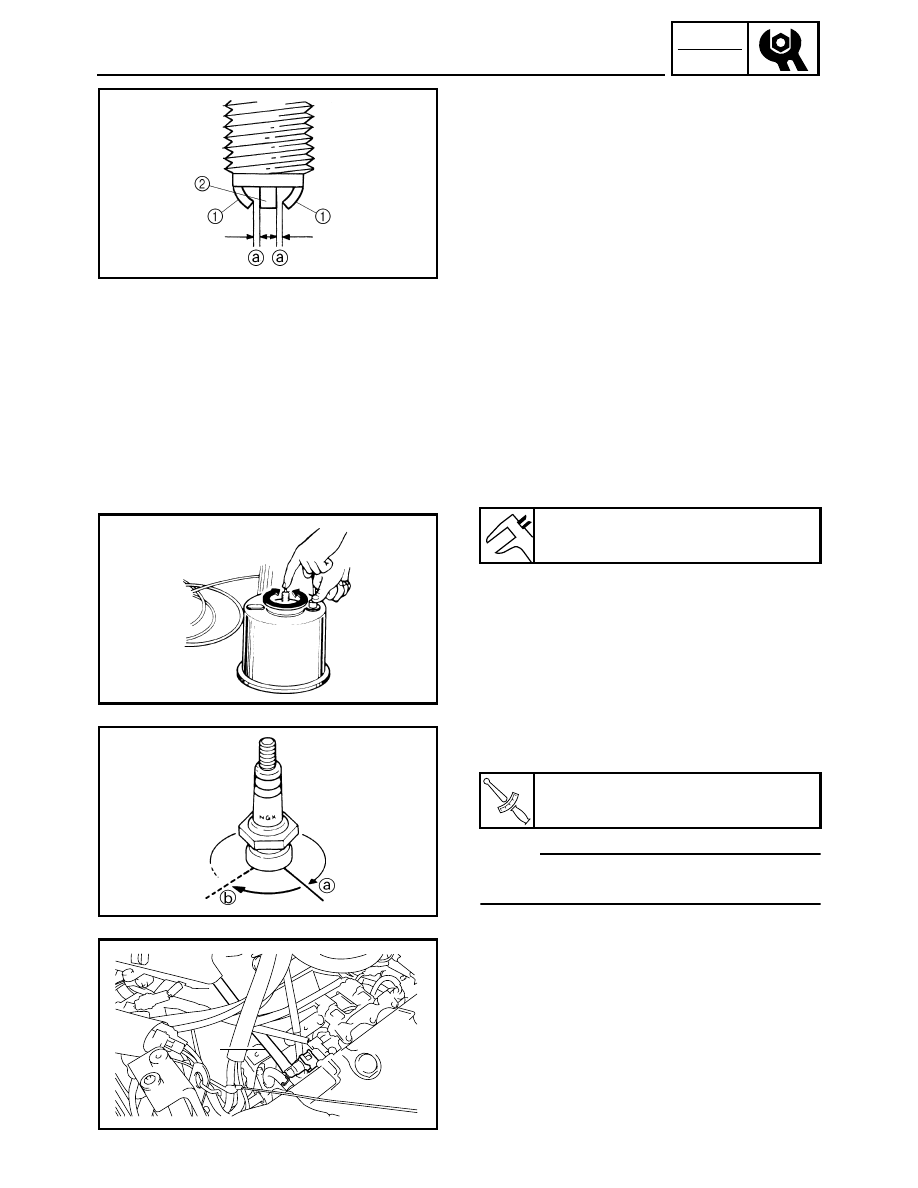

• Electrodes 1

Damage/wear

→ Replace the spark plug.

• Insulator color 2

Abnormal color

→ Replace the spark plug

Normal color is medium-to-light tan.

4. Measure:

• Spark plug gap

a

Out of specification

→ Regap.

Use a wire thickness gauge.

If necessary, clean the spark plugs with a spark

plug cleaner.

Standard spark plug:

NGK R CR9EKB (NGK)

Before installing a spark plug, clean the gasket sur-

face and spark plug surface.

5. Install:

• Spark plugs

NOTE:

Finger-tighten

a the spark plug before torquing b

it to specification.

Spark plug gap:

0.6 ~ 0.7 mm (0.024 ~ 0.028 in)

T

R

.

.

Spark plug:

13 Nm (1.3 m · kg, 9.4 ft · lb)

FUEL LINE INSPECTION

1. Remove:

• Headlight assembly (PZ50/PZ50GT/PZ50FX/

PZ50M)

Refer to “COWLINGS” in CHAPTER 3.

2. Inspect:

• Fuel hose 1

• Fuel return hose

Cracks/damage

→ Replace.

1