Snowmobile Polaris 600 RUSH (2010 year). Manual - part 20

3.30

Engine/Cooling/Exhaust

9923311 - 2010-2012 PRO-RIDE RUSH/Switchback/RMK Service Manual

© 2011 Polaris Sales Inc.

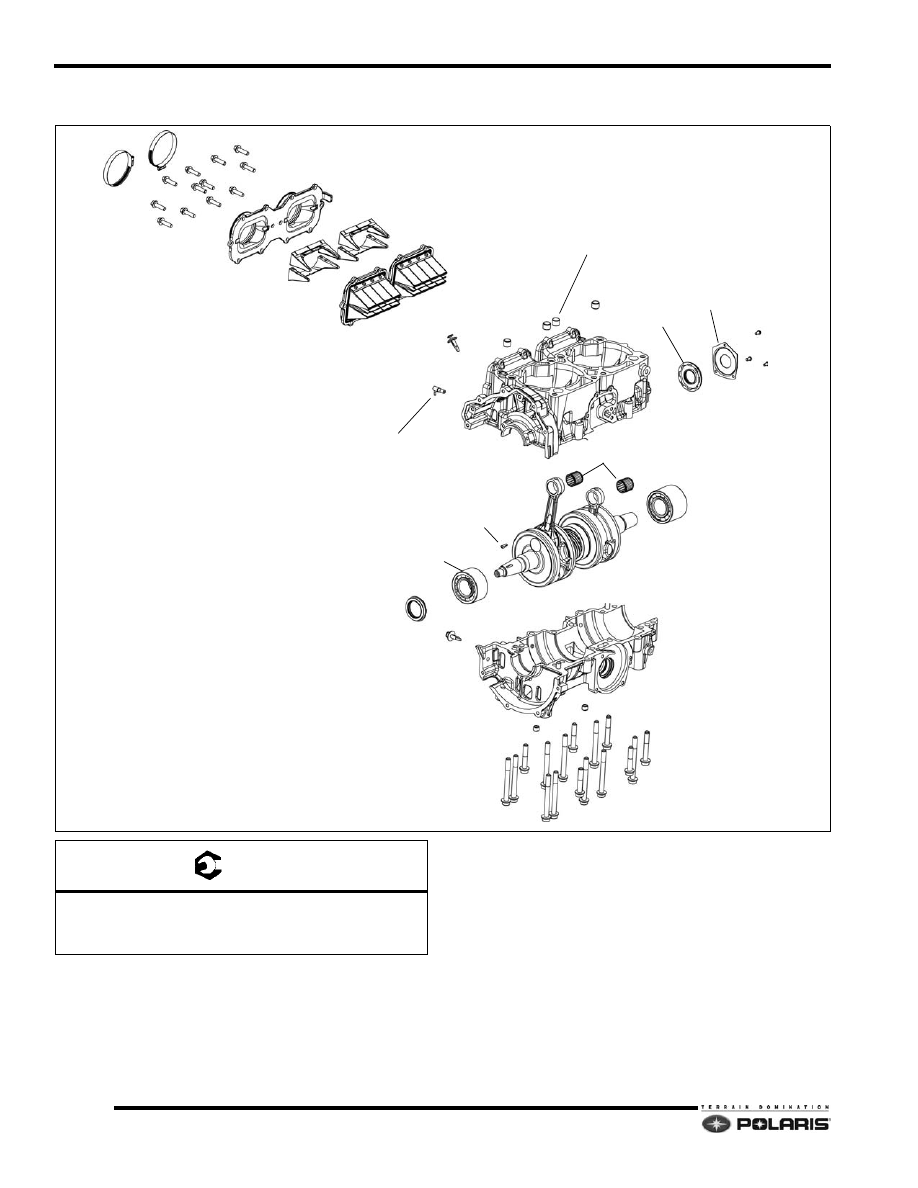

800 DC-CFI-2 Crankcase/Crankshaft

GEAR CLAMPS

ADAPTER PLATE

REED STUFFERS

REED BLOCKS

SEAL GUARD

PTO SEAL

ALIGNMENT DOWELS

MAG SEAL

MAG BEARING

FLYWHEEL KEY

PTO BEARING

WRIST PIN BEARINGS

OIL INJECTION CHECK VALVE QTY. 5

ALIGNMENT DOWELS

A

B

C

STATOR WIRE RETAINER

STATOR WIRE RETAINER

= T

A: 9 ft-lb (12 Nm)

B: 22 ft-lb (30 Nm) - Apply Loctite® 242™

C: 10 ft-lb (13 Nm) - Apply Pipe Sealant