Snowmobile Polaris IQ (2007-2008 year). Manual - part 73

11.4

Battery and Electrical Systems

BATTERY TESTING

Testing Procedures

Batteries should be kept at or as near full charge as possible. If

the battery is stored or used in a partially charged condition, hard

crystal sulfication will form on the plates, reducing their

efficiency and possibly ruining the battery.

Open Circuit Voltage Test (OCV)

Check static battery voltage with multimeter. Voltage should be

no less than 12.8 Vdc. Charge battery if voltage is lower than

12.8 Vdc.

Load Test

A battery may pass the OCV test, but still not have the storage

capacity necessary to properly function.

1.

Connect multimeter to the battery as if performing the

OCV test.

2.

Turn the engine over using the electric starter.

3.

Replace battery if Vdc drops below 9.5Vdc.

NOTE: Battery load test tools can be purchased

commercially. Follow the manufactures’ instructions

for use.

Specific Gravity Test (Conventional Battery)

NOTE: Do not attempt to open the vent cover on a

fresh pack battery.

A battery hydrometer (PN 2870836) can be used to measure

electrolyte strength or specific gravity. As the battery goes

through the charge/discharge cycle, the electrolyte goes from a

heavy, more acidic state at full charge to a light, more water state

when discharged. The hydrometer can measure state of charge

and differences between cells in a multi-cell battery. Readings of

1.270 or greater should be observed in a fully charged battery.

Differences of more than 0.025 between the lowest and highest

cell readings indicate a need to replace the battery.

Off Season Storage

To prevent battery damage during extended periods of non-use,

the following maintenance items must be performed.

1.

Remove battery from machine and wash the case and

battery tray with a mild solution of baking soda and water.

Rinse with of fresh water after cleaning.

2.

Using a wire brush or knife, remove any corrosion from the

cables and terminals.

3.

Charge at a rate no greater than 1/10 of the battery's amp/

hr. capacity.

4.

Store the battery in a cool, dry place.

NOTE: Stored batteries lose their charge at the rate

of 1% per day. They should be fully recharged every

30 to 60 days during a non-use period. If stored

during winter months, the electrolyte will freeze at

higher temperatures as the battery discharges.

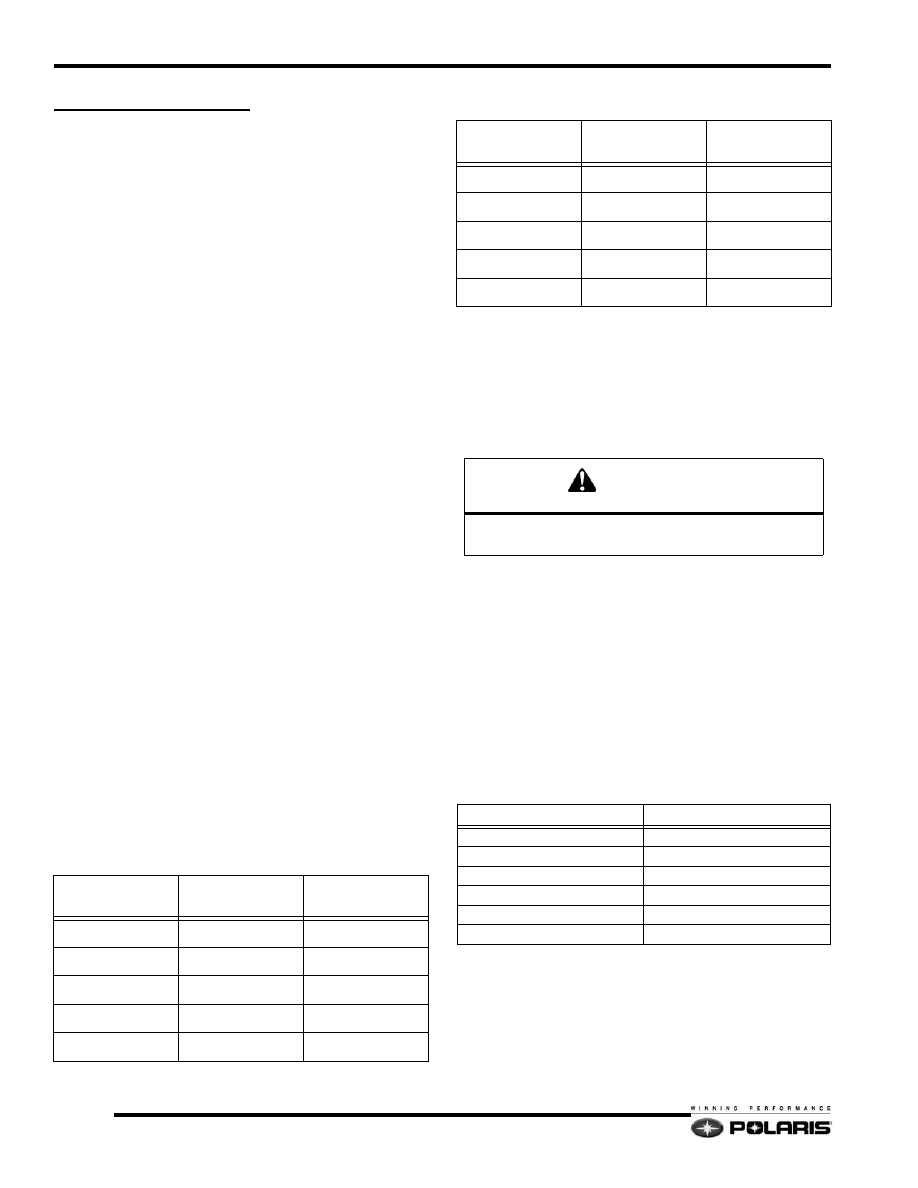

Battery Voltage

STATE OF CHARGE

CONVENTIONAL

LEAD-ACID

YUMACRON TYPE

100% CHARGED

12.60v

12.70v

75% CHARGED

12.40v

12.50v

50% CHARGED

12.10v

12.20v

25% CHARGED

11.90v

12.00v

0% CHARGED

< 11.80v

< 11.90v

Battery Voltage Per Cell

STATE OF CHARGE

CONVENTIONAL

LEAD-ACID

YUMACRON TYPE

100% CHARGED

1.265v

1.275v

75% CHARGED

1.210v

1.225v

50% CHARGED

1.160v

1.175v

25% CHARGED

1.120v

1.135v

0% CHARGED

< 1.100v

< 1.115v

CAUTION

D

O

NOT

ALLOW

ANY

OF

THE

BAKING

SODA

SOLUTION

TO

ENTER

THE

BATTERY

OR

THE

ACID

WILL

BE

NEUTRALIZED

.

Specific Gravity Freezing Point

Specific Gravity of Electrolyte

Freezing Point

1.265

-75_F (-59_C)

1.225

-35_F (-37_C)

1.200

-17_F (-27_C)

1.150

5_F (-15_C)

1.100

18_F (-8_C)

1.050

27_F (-3_C)