Snowmobile Polaris (2006 year). Manual - part 18

3.8

MAINTENANCE

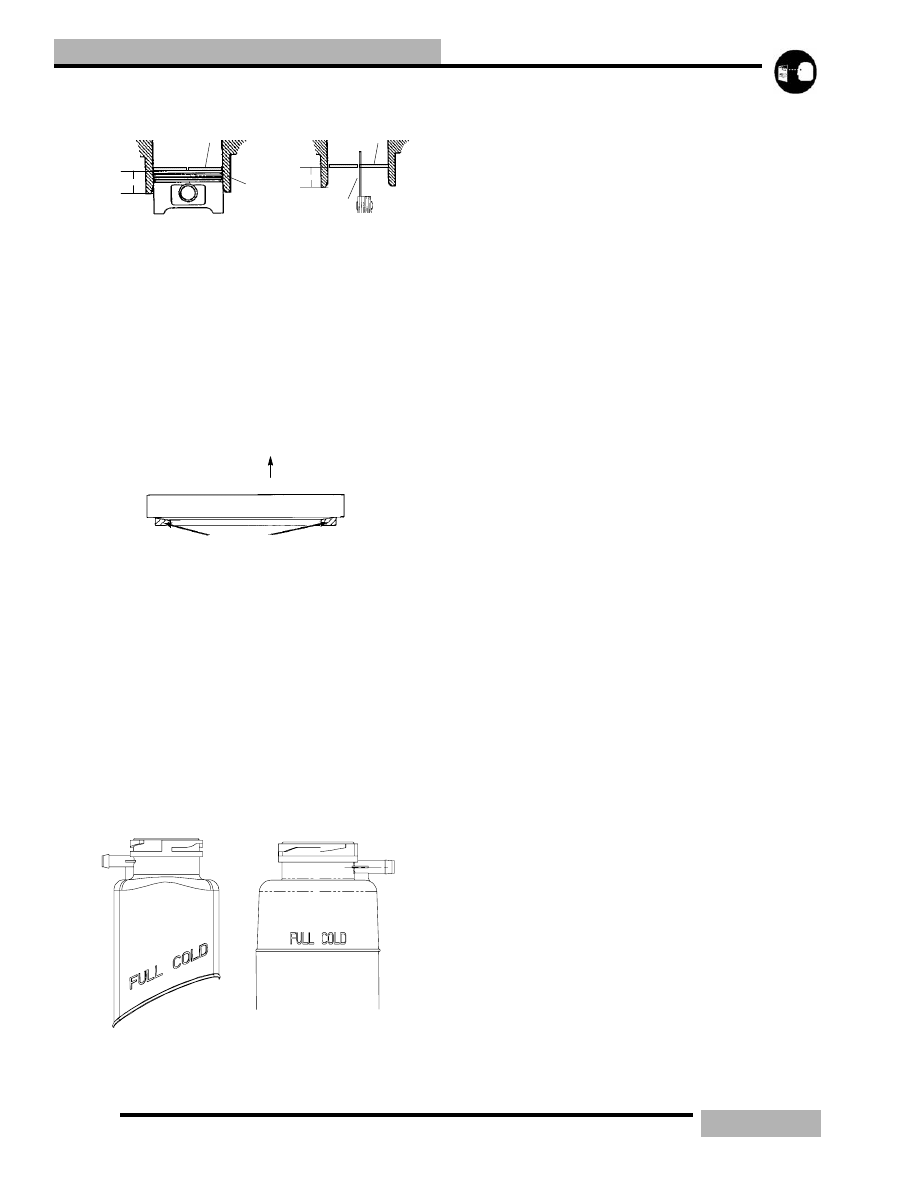

PISTON RING INSTALLED GAP

Position the ring 1/2" (1.3 cm) from the top of the cylinder

using the piston to push it squarely into place. Measure

installed gap with a feeler gauge at both the top and bottom of

the cylinder.

NOTE: A difference in end gap indicates cylinder

taper. The cylinder should be measured for

excessive taper and out of round. Replace rings if

the installed end gap exceeds the service limit.

Always check piston ring installed gap after re-

boring a cylinder or when installing new rings.

Piston rings are installed with marking or beveled side up see

diagram above.

COOLANT LEVEL

Coolant level in the coolant bottle must be maintained to

prevent overheating and serious engine damage. Check the

coolant with the engine temperature cold. The coolant level

should be at the FULL COLD level mark. If it is not add

coolant to the FULL COLD mark on the bottle. If you have

coolant over the FULL COLD level you may have air in the

system and need to “bleed” the air out of the system.

RECOMMENDED COOLANT

Polaris snowmobiles use a premium 60/40 pre-mix antifreeze.

This premium antifreeze is mixed with deionized water for

better protection for aluminum cooling. This pre-mix is good

for temperatures down to -62_F (-52_C). Replace coolant

every 2 years or if contaminated.

• 60/40 Pre-mix Quart PN 2871534

• 60/40 Pre-mix Gallon PN 2871323

• 60/40 Pre-mix 2.5 Gallon PN 2872278

COOLING SYSTEM BLEEDING

1.

Allow the cooling system to cool completely.

2.

Check the coolant reservoir and make sure it is at the

FULL COLD mark.

3.

Place the snowmobile in its normal riding position and

apply the parking brake and run the engine at the specified

idle RPM until the thermostat opens up.

4.

Open the bleed screw (A) at the top of the water outlet

Piston Ring

Feeler Gauge

1/2

s (1.3cm.)

1/2

s (1.3cm.)

Cylinder

Piston Ring

Straight Edge

Keystone Piston Ring Cutaway

Up