Snowmobile Polaris (2006 year). Manual - part 17

3.4

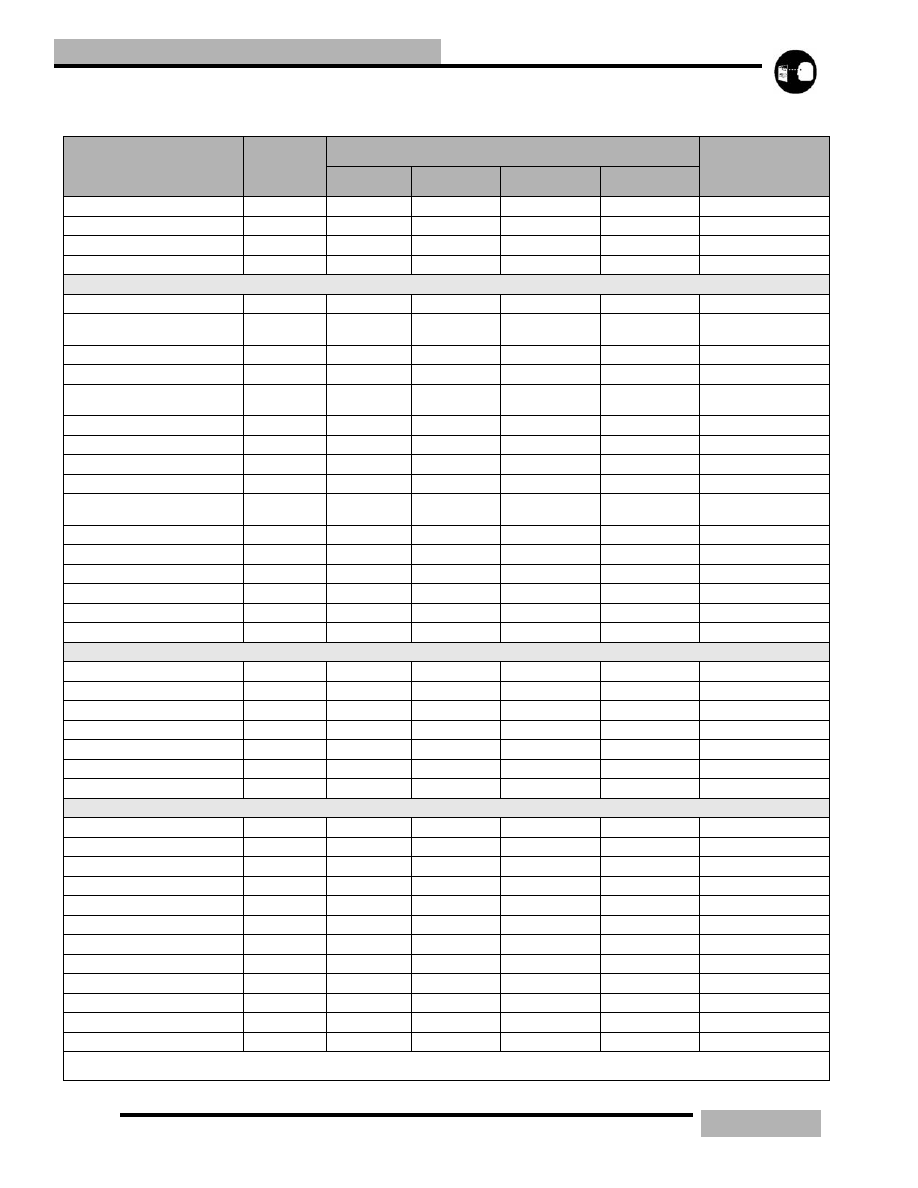

MAINTENANCE

Brake Disc

I

I

I

I

Parking Brakes

I

I

I

I

I

Brake System

I

Brake Fluid

R

FUEL MANAGEMENT

Pilot Air Screws

I

I

I

Carburetor

(synchronize)

I

I

I

Idle RPM

I

I

I

Throttle Lever

I

I

I

I

I

Oil Pump Lever

(synchronize)

I

I

I

Throttle Cable

L

L

L

Choke Cable

L

L

L

Choke

I

I

I

Vent Lines

I

I

I

I

Throttle Position

Sensor

I

I

I

Fuel Lines

I

I

I

I

I

Fuel Filter

R

R

Oil Filter

R

R

Oil Lines

I

I

I

Air Box

I

I

I

I

I

Drain and Water Traps

I

I

I

ELECTRICAL

Auxiliary Shut-Off Switch

I

I

I

I

I

I

Throttle Safety Switch

I

I

I

I

I

I

Ignition Switch

I

I

I

I

I

I

Taillight

I

I

I

I

I

I

Brakelight

I

I

I

I

I

I

Headlight

I

I

I

I

I

I

Tether Switch and Strap

I

I

I

I

I

I

CHASSIS

Ski Toe Alignment

I

I

I

Suspension Mounting Bolts

I

I

I

I

I

I

Steering Fasteners

I

I

I

I

C

Rear Suspension Fasteners

I

I

I

I

I

Suspension Shock Oil

I

I

I

I

Cooling Fins and Shroud

I

I

I

I

Drive Shaft Bearing

L

L

L

I

Jackshaft Bearings

L

L

L

I

Skags (Wear Bars)

I

I

I

I

I

I

Ski Saddle/Spindle Bolts

I

I

I

I

I

I

Drive Chain Tension

I

I

I

I

I

Hood Straps

I

I

I

I

I

I

Table 3-1: Maintenance Intervals

Item

Pre-Ride

Frequency Miles (km)

Pre-

Season

150 (240)

500 (240)

1000 (1600)

2000 (3200)

I:Inspect (clean, adjust, tighten, lubricate, replace if necessary) C:Clean R:Replace L:Lubricate