COMBINE HARVESTER AW70V, VNQ, AW82V, VNQ. Manual - part 14

Operation

57

1- Step the brake pedal to the floor and engage the

parking brake lock after the combine is stopped.

2- Lift up the header slightly, and raise the reel to the

highest position.

3- Put the threshing clutch lever and header clutch

lever to “ON”.

4- Pull the accelerator lever to make the tachometer

into the “Green Zone”.

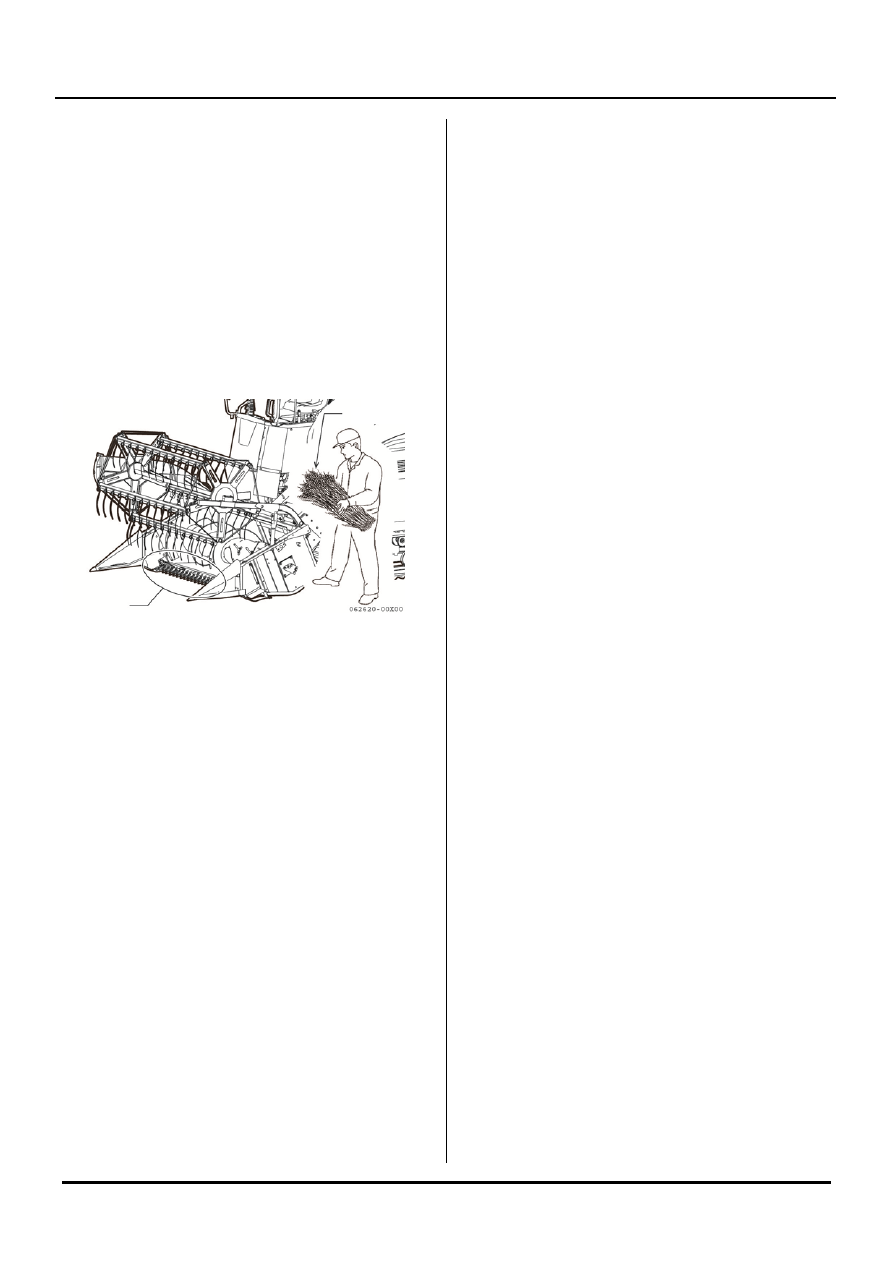

5- Put the crops manually harvested into the platform

auger gradually in small amount.

Manual

harvesting

Feeding auger