BMW Motorcycle (R1100RT, R1100RS, R850/1100GS, R850/1100R). Manual - part 25

21.10

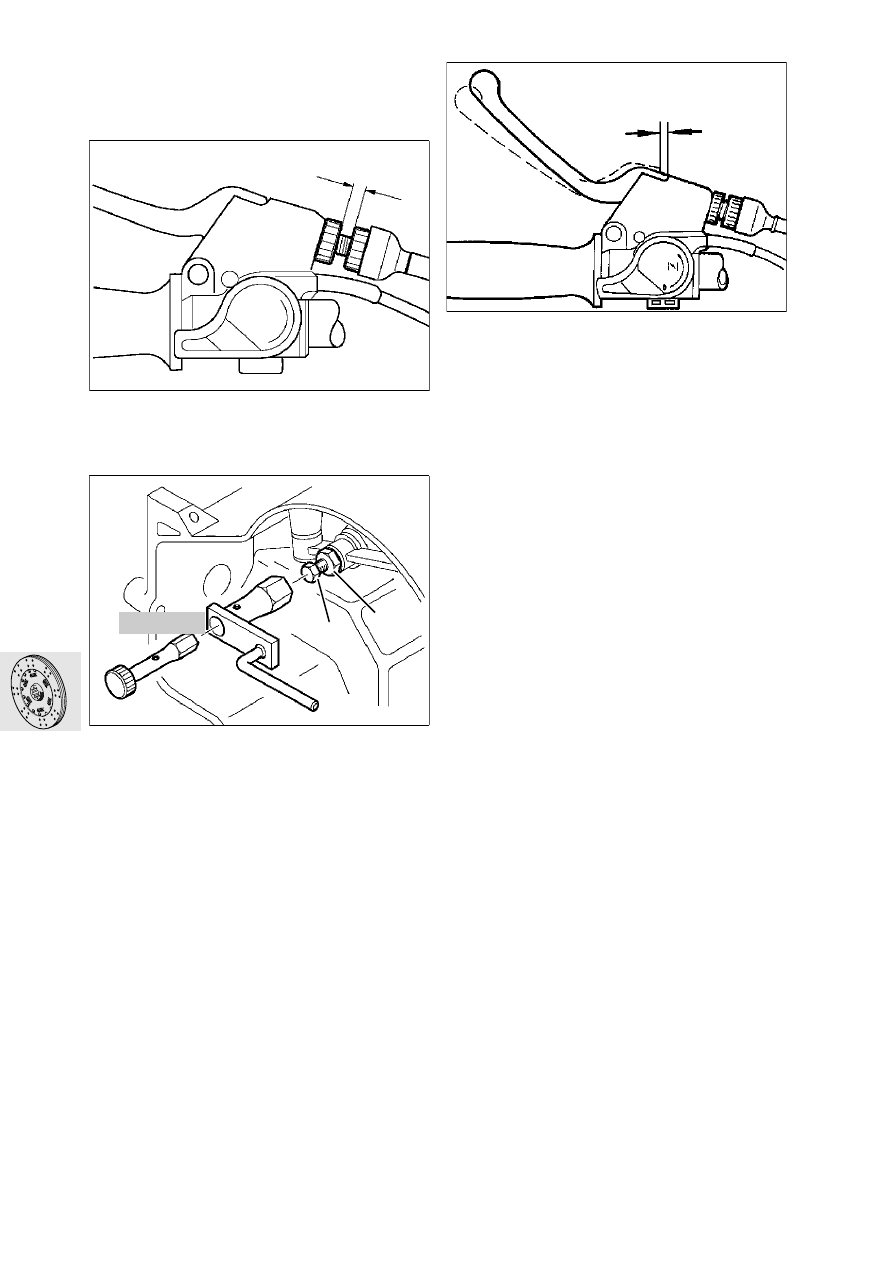

Adjusting clutch operating clear-

ance

•

Turn adjusting screw to obtain distance A.

Distance A:.................................. 12 mm (0.472 in)

•

[GS] If necessary, detach the hydraulic spring

adjusted with a 6 mm (0.24 in) Allen key,

BMW No. 31 5 600.

•

[RT] If necessary, detach the power socket

holder.

•

Using socket wrench, BMW No. 21 3 610,

loosen locknut (1) for adjusting screw (2) at

clutch release lever.

•

Set to distance B at the handlebar lever by turn-

ing adjusting screw (2) on the clutch release le-

ver.

Distance B: ................................... 7 mm (0.276 in)

X

Tightening torque:

Locknut on adjusting screw ......................... 22 Nm

A

RS210020

21 3 610

2

1

RS210030

B

RS210040