BMW AG Motorcycle (R 850 C, R 1200 C). Manual - part 3

00.16

Checking battery acid level/topping

up if necessary, cleaning/greasing

battery posts

(Inspections III and IV)

•

Release the rubber strap holding the battery.

•

Raise the battery and check its acid level.

•

Top up battery acid level with distilled water as

far as the MAX mark.

Protective

battery-post grease: ...............e.g. Bosch Ft 40 V1

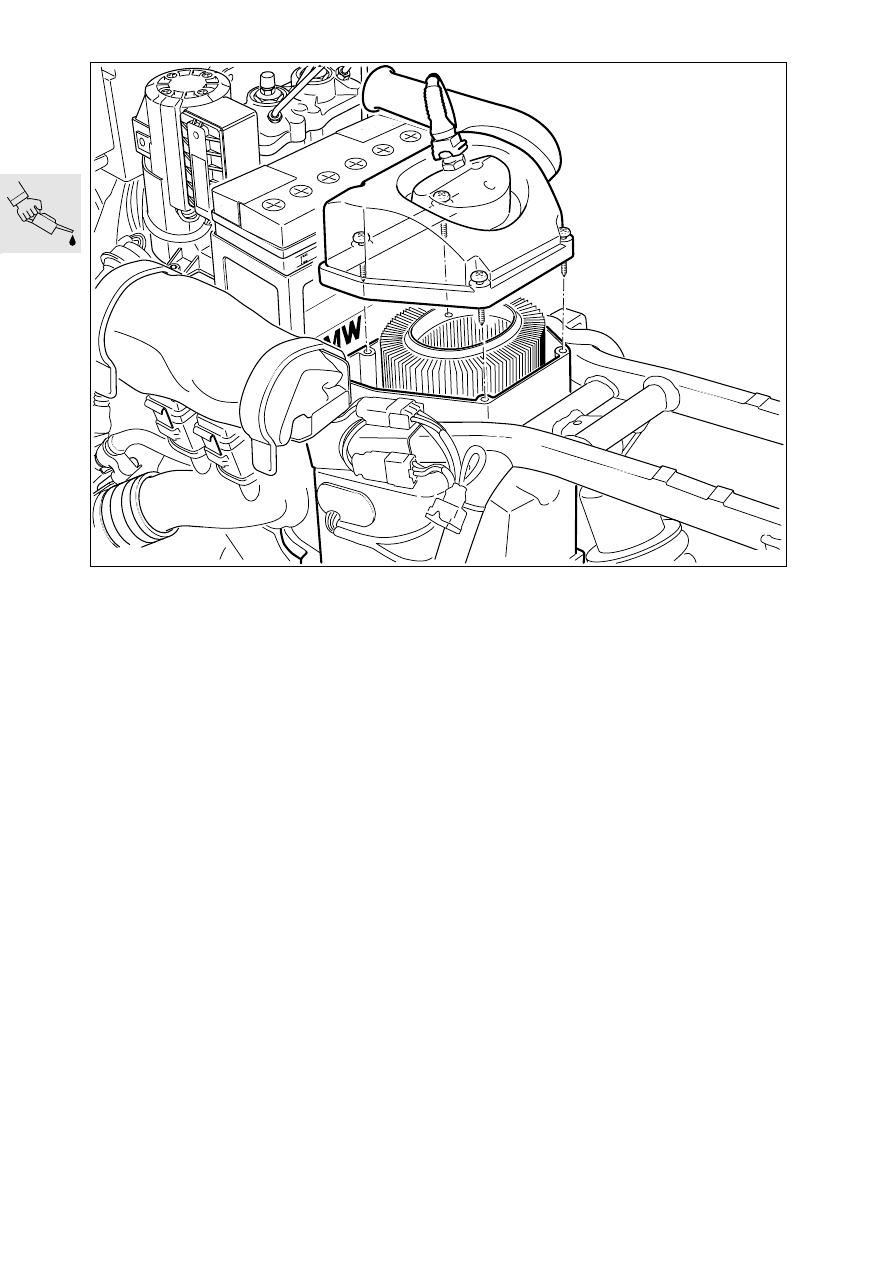

Renewing intake air cleaner

element

(Inspection III)

In very dirty and dusty operating conditions,

renew every 10 000 km (6 000 miles) or even

more frequently if necessary

•

Detach and raise the upper part of the air cleaner

housing.

•

Renew air cleaner element.

•

Install the fuel tank.

•

Note correct path of vent lines.

•

Install the left/right trim panels.

X

Tightening torque:

Fuel tank to rear frame ................................. 10 Nm

C000020