BMW AG Motorcycle (R 850 C, R 1200 C). Manual - part 1

Order No. 01 71 0 008 872

UX-VS-2, 06.99

Printed in Germany

Customer

Licence plate No.

Order No.

Mechanic’s signature

BM

W In

s

p

e

c

ti

o

n

a

t 1

0

00

km

(6

0

0

mi

le

s)

BM

W S

e

rvi

c

e

ev

er

y

10

0

0

0

km

(6

00

0 mi

le

s)

BM

W In

s

p

e

c

ti

o

n

ev

er

y

20

00

0 k

m

(1

2

0

0

0

mi

le

s)

BM

W

A

n

n

ual

S

e

rv

ic

e

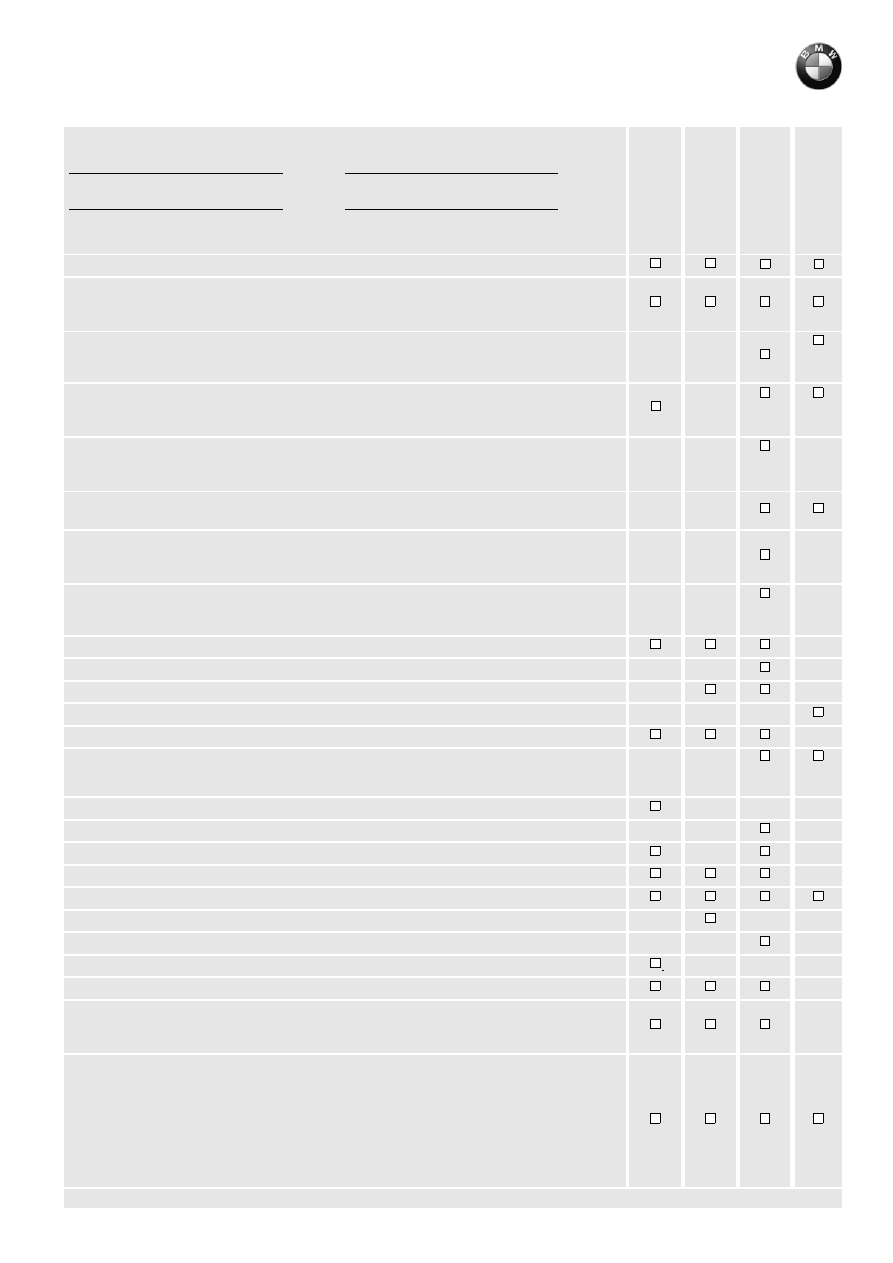

Read the fault code memory with the MoDiTeC

Change oil while at regular operating temperature and renew the oil filter element

if motorcycle is used only for short journeys or at outside temperatures under 0°C (32 °F), every

3 months, but at least every 3 000 km (1 800 miles)

*

)

Change oil in gearbox while at operating temperature

at least every 2 years

*

)

every

2 years

Change oil in rear wheel drive while at regular operating temperature;

if necessary, clean inductive sensor on rear wheel

every 40 000 km (24 000 miles) or at least every 2 years

*

)

40 000

(24 000)

every

2 years

Renew fuel filter *

)

normally every 40 000 km (24 000 miles), if fuel quality is poor every 20 000 km (12 000 miles)

40 000

(24 000)

Check battery acid level, if necessary add distilled water

Clean and grease the battery terminals, if necessary

Renew intake air filter element

in very dusty or dirty operating conditions, renew the intake air filter element every 10 000 km

(6 000 miles) or even more often if necessary

*

)

Renew Poly-V belt *

)

renew Poly-V belt every 60 000 km (36 000 miles); do not adjust

60 000

(36 000)

Check brake fluid level at front and rear and top up if necessary *

)

Check operation of brake system and freedom from leaks; repair/replace items if nec. *

)

Examine brake pads and discs for wear, renew if necessary *

)

Change the brake fluid annually

Check clutch fluid level

Change the clutch fluid

every 40 000 km (24 000 miles) or at least every 2 years

*

)

40 000

(24 000)

every

2 years

Check tightness of rear wheel studs

Check rear wheel bearing play by tilting wheel

Check swinging arm bearings (zero play); adjust if necessary *

)

Grease the side stand pivot

Check function of side stand contact switch

Check condition of spark plugs

Renew spark plugs *

)

Check security of cylinder head nuts

Check/adjust valve clearances

Check throttle cable for free movement, abrasion and kinking; renew if necessary *

)

Check cable play

Check synchronisation and eliminate leaks *

)

Final inspection with road safety and functional check:

–

Condition of tyres and wheels, rims and spokes if applicable, tyre pressures

–

Lights and signalling equipment

–

Telltale and warning lights

–

Clutch, gear shift

–

Front and rear brakes, steering

–

Instruments

–

If necessary, test ride

*

)

Charged as an additional item

BMW AG Motorcycle Division

Maintenance schedule

R 1100 S / R 850/1200 C / R 1150 GS