Suzuki Grand Vitara JB627. Manual - part 8

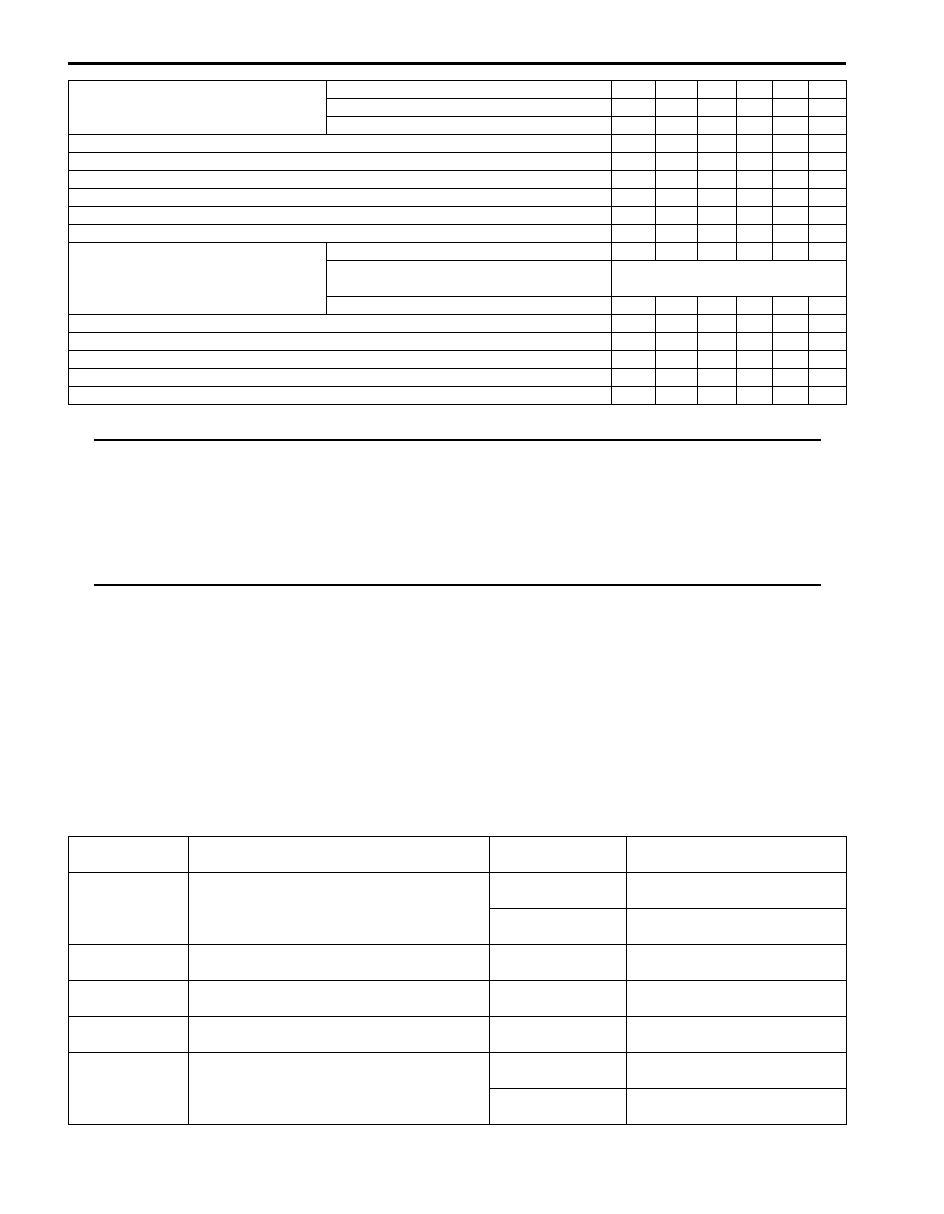

0B-2 Maintenance and Lubrication:

NOTE

• “R”: Replace or change

• “I”: Inspect and correct, replace or lubricate if necessary

• For Sweden, items with asterisk (*) should be performed by odometer reading only.

• For spark plugs, replace every 50,000 km if the local law requires.

• Nickel spark plug: BKR6E-11 (NGK) or K20PR-U11 (DENSO)

• Iridium spark plug: IFR6J11 (NGK)

Maintenance Recommended under Severe Driving Conditions

S6JB0B0205002

If the vehicle is usually used under the conditions corresponding to any severe condition code, IT IS RECOMMENDED

that applicable maintenance operation be performed at the particular interval as shown in the following table.

Severe condition code:

A: Repeated short trips

B: Driving on rough and/or muddy roads

C: Driving on dusty roads

D: Driving in extremely cold weather and/or salted roads

E: Repeated short trips in extremely cold weather

F: Leaded fuel use

G: – – – – – – – –

H: Towing a trailer (if admitted)

Clutch (fluid leakage, level) (I: ))

—

I

—

I

—

I

Tires (wear, damage, rotation) / wheels (damage) (I: ) /))

I

I

I

I

I

I

Suspension system (tightness, damage, rattle, breakage) (I: ))

—

I

—

I

—

I

Steering system (tightness, damage, breakage, rattle) (I: ))

—

I

—

I

—

I

Drive shaft (axle) boots / Propeller shafts (I: ))

—

—

I

—

—

I

Manual transmission oil (leakage, level) (I: ) 1st 15,000 km only) (R: ))

I

—

R

—

—

R

Automatic transmission fluid

Fluid level (I: ))

—

I

—

I

—

I

Fluid change (R: ))

Replace every 165,000 km

(99,000 miles)

Fluid hose (I: ))

—

—

—

I

—

—

Transfer oil (leakage, level) (I: ))

I

—

I

—

I

—

Differential oil (leakage, level) (R: ) 1st 15,000 km only) (I: ))

R or I

—

I

—

I

—

Power steering (if equipped) (I: ))

I

I

I

I

I

I

All latches, hinges and locks (I: ))

—

I

—

I

—

I

HVAC air filter (if equipped) (I: )) (R: ))

—

I

R

—

I

R

Interval

Km (x 1,000)

15

30

45

60

75

90

Miles (x 1,000)

9

18

27

36

45

54

Months

12

24

36

48

60

72

Severe

Condition Code

Maintenance

Maintenance

Operation

Maintenance Interval

– B C D – – – – Engine accessory drive belt

I

Every 15,000 km

(9,000 miles) or 12 months

R

Every 45,000 km

(27,000 miles) or 36 months

A – C D E F – H Engine oil and oil filter

R

Every 7,500 km

(4,500 miles) or 6 months

– B – – – – – – Exhaust pipe mountings

I

Every 15,000 km

(9,000 miles) or 12 months

– B – – – – – – Suspension bolts and nuts

T

Every 15,000 km

(9,000 miles) or 12 months

– – C – – – – – Air cleaner filter *1

I

Every 2,500 km

(1,500 miles)

R

Every 30,000 km

(18,000 miles) or 24 months