Suzuki Grand Vitara JB416 / JB420. Manual - part 417

10B-34 Body Electrical Control System:

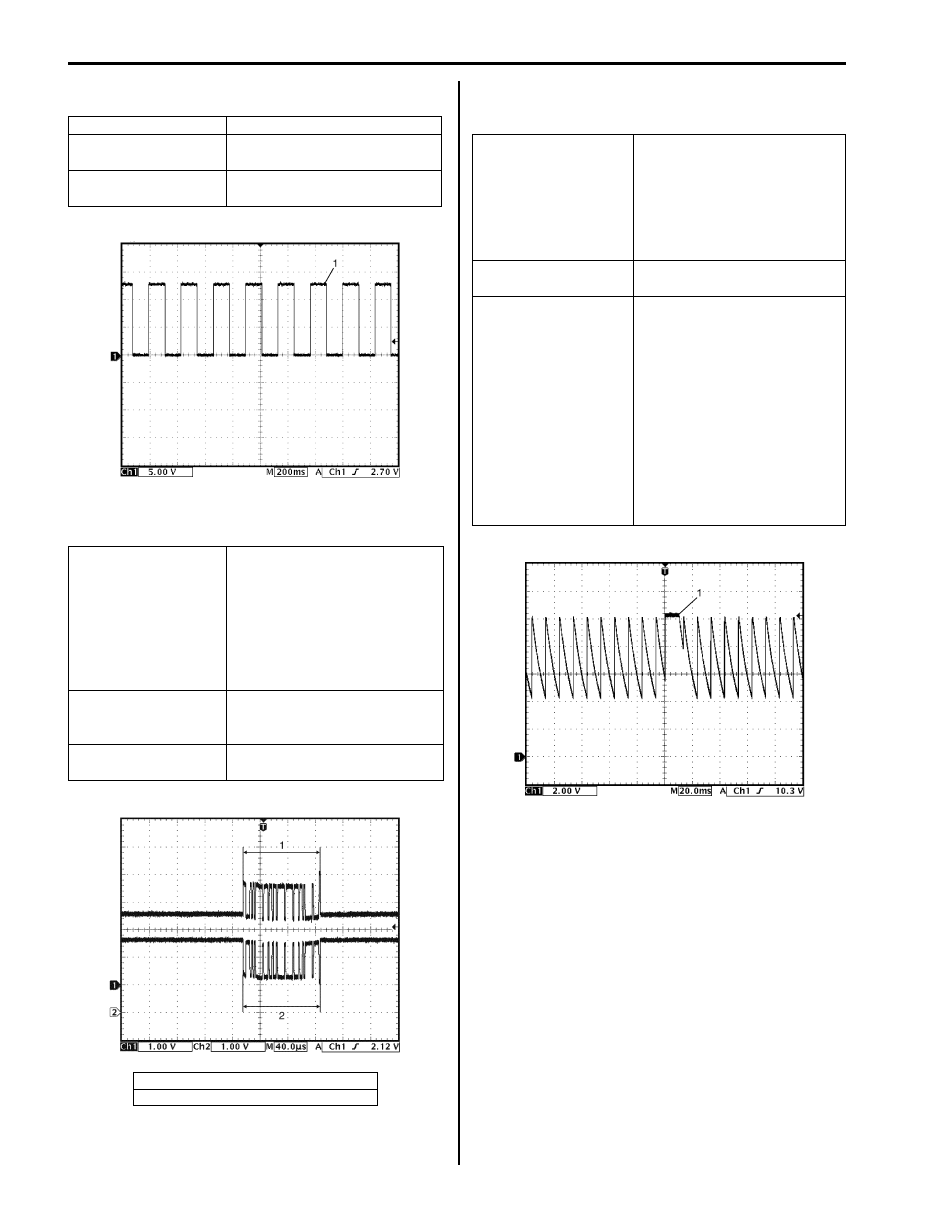

Reference waveform No. 5

Vehicle speed pulse output signal (1)

Reference waveform No. 6

CAN communication signal

Reference waveform No. 7

Brake fluid level, parking brake or driver seat belt switch

signal (1)

Measurement terminal CH1: “G30-22” to “G30-12”

Oscilloscope setting

CH1: 5 V / DIV

TIME: 200 ms / DIV

Measurement

condition

Vehicle speed at 10 km/h (6

mph)

Measurement terminal CAN communication signal for

DLC

CH1: “G31-1” to “G30-12”

CH2: “G31-3” to “G30-12”

CAN communication signal for

each control module

CH1: “G31-2” to “G30-12”

CH2: “G31-4” to “G30-12”

Oscilloscope setting

CH1: 1 V / DIV

CH2: 1 V / DIV

TIME: 40

µs / DIV

Measurement

condition

Ignition switch is at ON position

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I5JB0AA20017-01

I5JB0AA20018-01

Measurement terminal Brake fluid level switch signal:

CH1: “G31-7” to “G30-12”

Parking brake switch signal:

CH1: “G31-8” to “G30-12”

Driver side seat belt switch

signal:

CH1: “G31-40” to “G30-12”

Oscilloscope setting

CH1: 2 V / DIV

TIME: 20 ms / DIV

Measurement condition Brake fluid level switch:

• Ignition switch is at ON

position and brake fluid level

is at specified level

Parking brake switch:

• Ignition switch is at ON

position and parking brake

lever is released.

Driver side seat belt switch:

• Ignition switch is at ON

position and driver seat belt

is fastened

I5JB0AA20019-01