Suzuki Grand Vitara JB416 / JB420. Manual - part 408

10A-7 Cruise Control System:

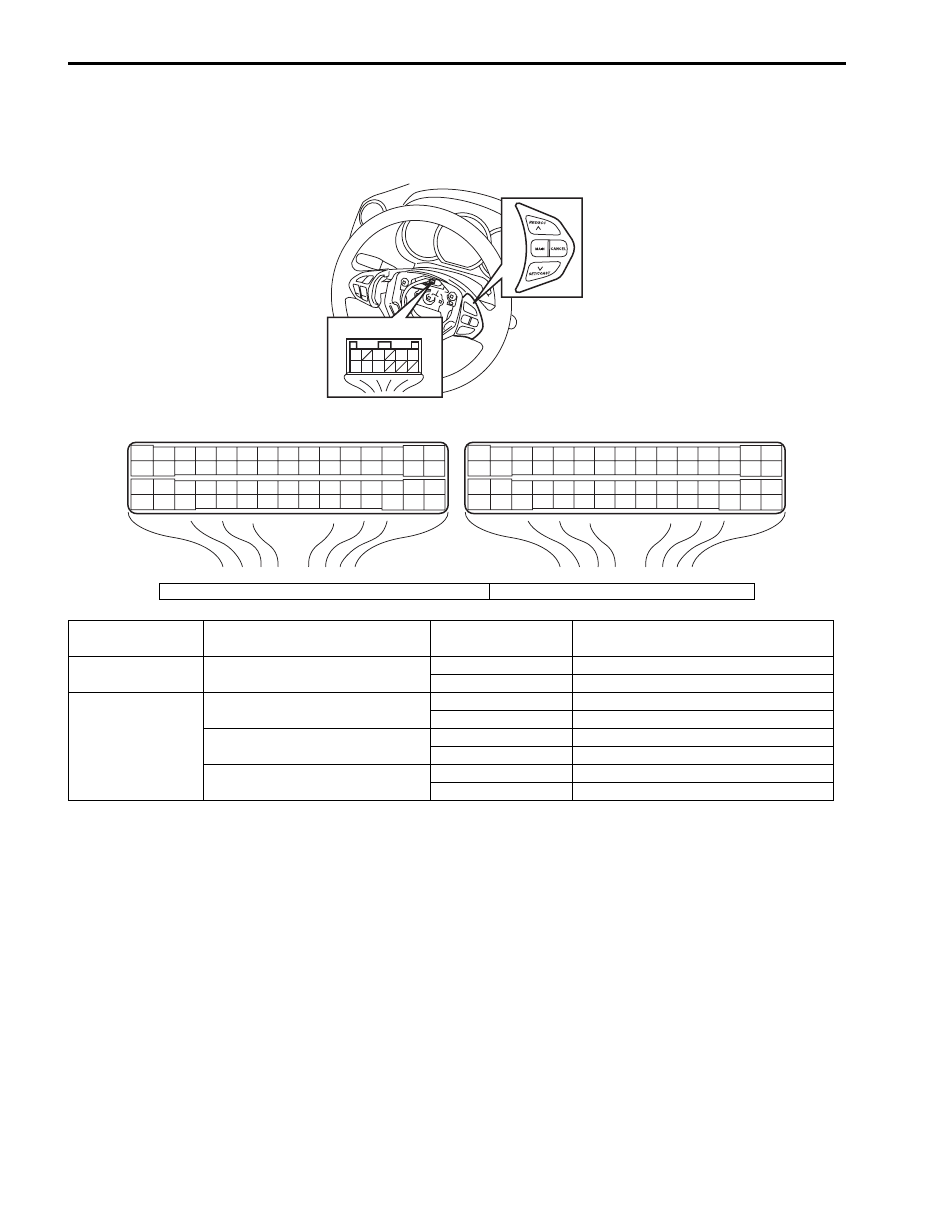

Resistance Check

1) Remove driver air bag (inflator) module from steering wheel referring to “Driver Air Bag (Inflator) Module Removal

and Installation in Section 8B”.

2) Measure resistance between the following terminals with ECM connector disconnected.

E23

C37

3

4

18

19

5

6

7

10

11

17

20

47

46

49

50

51

21

22

52

16

25

9

24

14

29

55

57

54 53

59

60

58

2

26

27

28

15

30

56

48

32

31

34

35

36

37

40

42

39 38

44

45

43

41

33

1

12

13

23

8

3

4

18

19

5

6

7

10

11

17

20

47

46

49

50

51

21

22

52

16

25

9

24

14

29

55

57

54 53

59

60

58

2

26

27

28

15

30

56

48

32

31

34

35

36

37

40

42

39 38

44

45

43

41

33

1

12

13

23

8

1

5

3

6

7 8 9

G54

[A]

[B]

I5JB0AA10005-03

[A]: Cruise control switch connector (viewed from harness side)

[B]: ECM connector (viewed from harness side)

Terminals

Circuit

Standard

Resistance

Condition

G54-1 – E23-6

MAIN switch circuit

No continuity

MAIN switch is not pressed.

About 1

Ω

MAIN switch is pressed.

E23-21 – E23-22

CANCEL switch circuit

No continuity

CANCEL switch is not pressed.

About 1.5

Ω

CANCEL switch is pressed.

RES/ACC switch circuit

No continuity

RES/ACC switch is not pressed.

About 911

Ω

RES/ACC switch is pressed.

SET/COAST switch circuit

No continuity

SET/COAST switch is not pressed.

About 222

Ω

SET/COAST switch is pressed.