Suzuki Grand Vitara JB416 / JB420. Manual - part 43

1A-121 Engine General Information and Diagnosis:

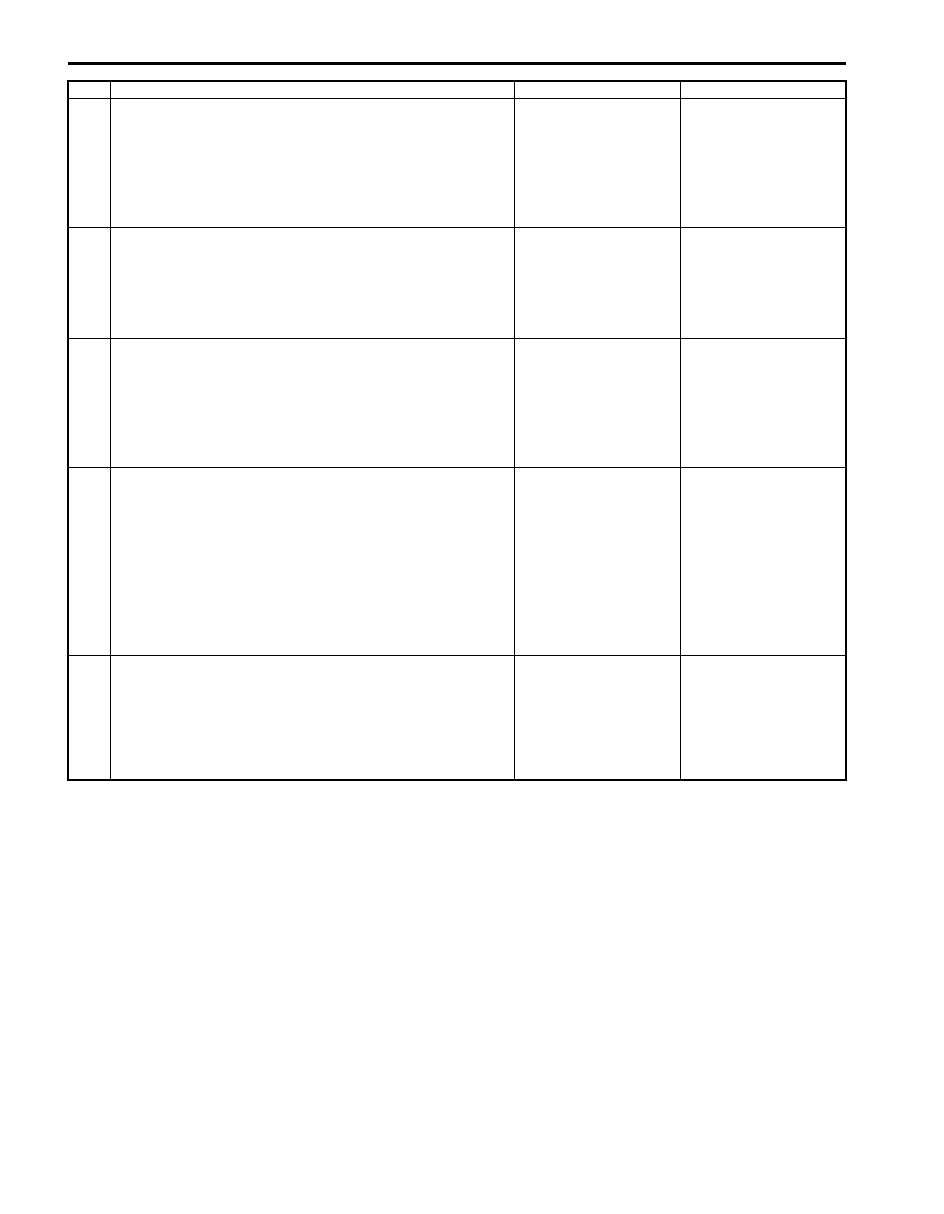

7

Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “WHT” and “RED” wire

terminals of electric throttle body assembly connector.

Is resistance infinity?

Go to Step 8.

“RED” wire is shorted to

“WHT” wire.

8

Wire harness check

1) Turn ON ignition switch.

2) Measure voltage between “C37-40” terminal of ECM

connector and engine ground.

Is voltage 0 V?

Substitute a known-

good ECM and recheck.

“RED” wire is shorted to

power circuit.

9

Ground circuit check

1) Turn OFF ignition switch.

2) Measure resistance between “GRN” wire terminal of

electric throttle body assembly connector and engine

ground.

Is resistance below 3

Ω

?

Go to Step 11.

Go to Step 10.

10 Ground circuit check

1) Remove ECM from its bracket with ECM connectors

connected.

2) Check for proper connection of ECM connector at “C37-

41” terminal.

3) Measure resistance between “C37-41” terminal of ECM

connector and engine ground with ignition switch turned

OFF.

Is resistance below 3

Ω

?

“GRN” wire is open or

high resistance circuit.

Faulty ECM ground

circuit. If circuit is OK,

substitute a known-

good ECM and recheck.

11 Electric throttle body assembly check

1) Check throttle position sensor referring to “Throttle

Position Sensor Performance Check” under “Electric

Throttle Body Assembly On-Vehicle Inspection in

Section 1C”.

Is output voltage within specified value?

Substitute a known-

good ECM and recheck.

Replace electric throttle

body assembly.

Step

Action

Yes

No