Suzuki Grand Vitara JB416 / JB420. Manual - part 10

0B-12 Maintenance and Lubrication:

Manual Transmission Oil Change

S5JB0A0206031

Change transmission oil with new specified oil referring

to “Manual Transmission Oil Change in Section 5B”.

Automatic Transmission Fluid Inspection

S5JB0A0206032

1) Inspect transmission case for evidence of fluid

leakage. Repair leaky point, if any.

2) Make sure that vehicle is placed level for fluid level

check.

3) Check fluid level referring to “A/T Fluid Level Check

in Section 5A”. If fluid level is low, replenish specified

fluid.

Automatic Transmission Fluid Change

S5JB0A0206033

1) Inspect transmission case for evidence of fluid

leakage. Repair leaky point, if any.

2) Make sure that vehicle is placed level.

3) Change fluid referring to “A/T Fluid Change in

Automatic Transmission Fluid Cooler Hose

Inspection

S5JB0A0206034

Check automatic transmission fluid cooler hose for fluid

leakage, cracks, damage and deterioration. Replace

hose and/or clamp if any faulty condition is found.

Transfer Oil Inspection (If Equipped)

S5JB0A0206049

1) Check transfer case for evidence of oil leakage.

Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Check oil level referring to “Transfer Oil Level Check:

Motor-Shift Type (Transfer with Shift Actuator) in

Section 3C” or “Transfer Oil Level Check: Non-Shift

Type (Transfer without Shift Actuator) in Section 3C”.

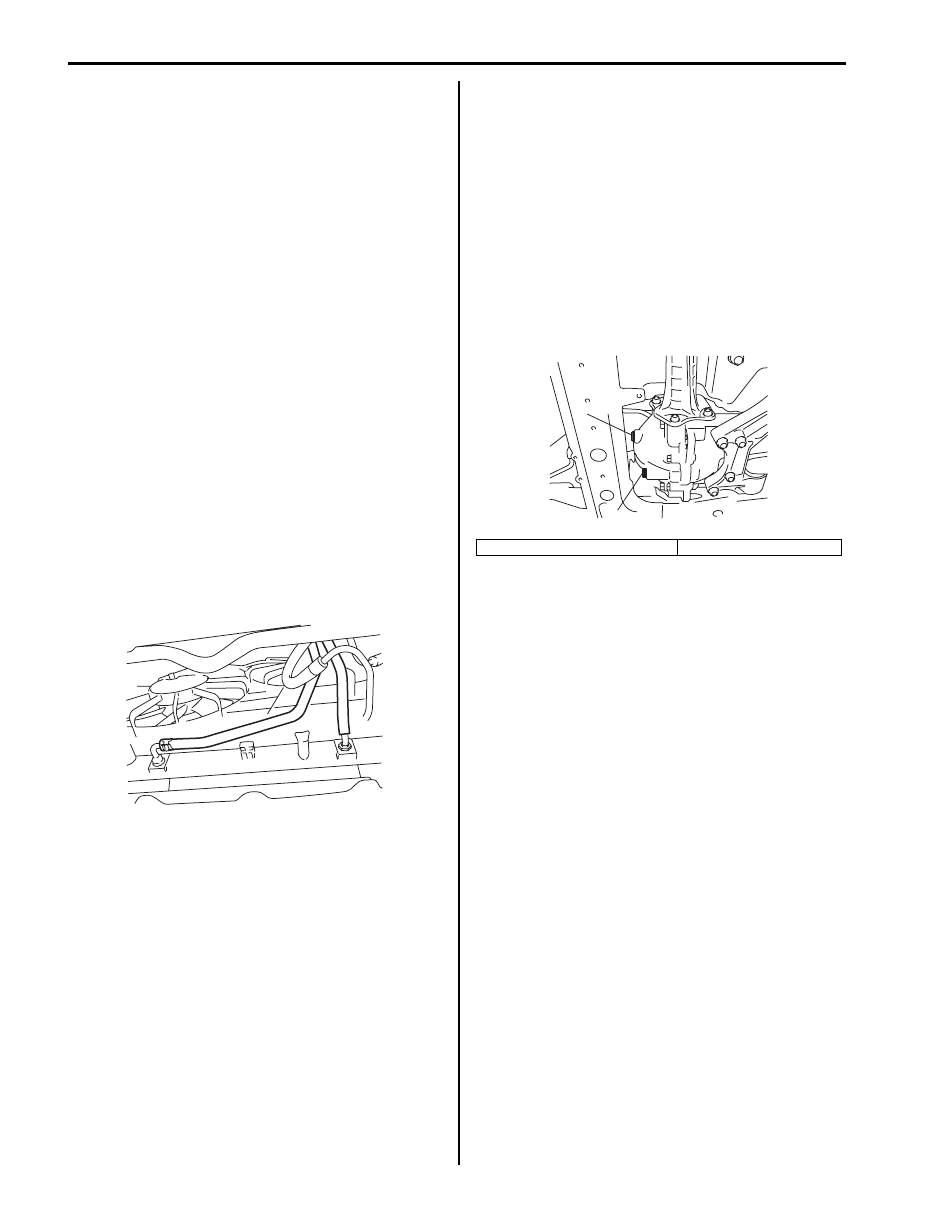

Differential Oil Inspection

S5JB0A0206035

1) Check differential for evidence of oil leakage.

Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Remove level / filler plug of differentials (front and/or

rear) and check oil level.

Oil level can be checked roughly by means of level

plug hole. That is, if oil flows out of level plug hole or

if oil level is found up to hole when level / filler plug is

removed, oil is properly filled.

If oil is found insufficient, pour specified amount of

specified oil.

4) Tighten level plug to specified torque.

For front differential, refer to “Front Differential Oil

Change: Front in Section 3B”.

For rear differential, refer to “Rear Differential Oil

Change: Rear in Section 3B”.

Transfer (If Equipped) and Differential Oil

Change

S5JB0A0206036

Change transfer oil and differential oil (front and rear)

with new specified oil respectively.

For transfer, refer to “Transfer Oil Change: Motor-Shift

Type (Transfer with Shift Actuator) in Section 3C” or

“Transfer Oil Change: Non-Shift Type (Transfer without

Shift Actuator) in Section 3C”.

For front differential, refer to “Front Differential Oil

Change: Front in Section 3B”.

For rear differential, refer to “Rear Differential Oil

Change: Rear in Section 3B”.

I5JB0A020025-02

1. Oil level / filler plug (Apply sealant.)

2. Drain plug (Apply sealant.)

1

2

I5JB0A020015-03