Suzuki Grand Vitara JB416 / JB420. Manual - part 3

00-9 Precautions:

Precaution for CAN Communication System

S5JB0A0000005

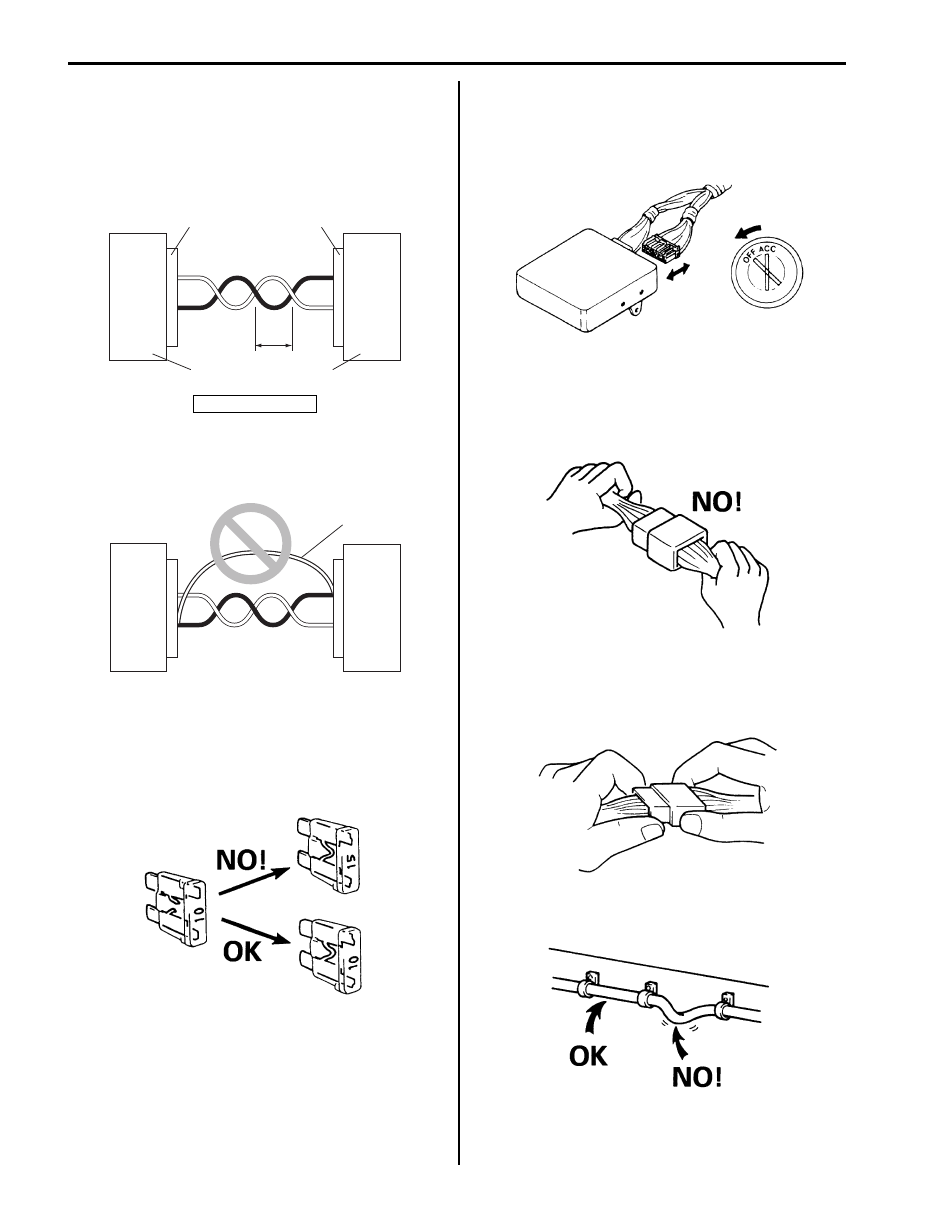

• The loose (1) in the wire harnesses twist of the CAN

lines except around the connector (3) should be within

100 mm (3.9 in.). Refer to the wiring diagram for the

CAN lines discrimination. Excessively-loosed lines

may be influenced by the electric noise.

• Do not connect terminals of the CAN line using a

bypass wire (1). Otherwise, the CAN line may be

influenced by the electric noise.

Precautions for Electrical Circuit Service

S5JB0A0000006

• When replacing a fuse, make sure to use a fuse of the

specified capacity. Use of a fuse with a larger capacity

will cause a damage to the electrical parts and a fire.

• When disconnecting and connecting coupler, make

sure to turn ignition switch OFF, or electronic parts

may get damaged.

• When disconnecting connectors, never pull the wiring

harness. Unlock the connector lock first and then pull

them apart by holding connectors themselves.

• When connecting connectors, also hold connectors

and put them together until they lock securely (a click

is heard).

• When installing the wiring harness, fix it with clamps

so that no slack is left.

2. Controller

3

3

2

2

1

I4JA01000002-01

1

I4JA01000003-01

I2RH01010038-01

I2RH01010039-01

I2RH01010040-01

I2RH01010041-01

I2RH01010042-01