Opel Frontera UE. Manual - part 652

POWER-ASSISTED STEERING SYSTEM

2A–21

4. Apply a thin coat of grease to the shaft for smooth

installation. Then install bellows.

5. Install band and clip.

6. Install tie-rod end and tighten lock nut.

Torque: 98N·m (10.0kg·m/72lbft)

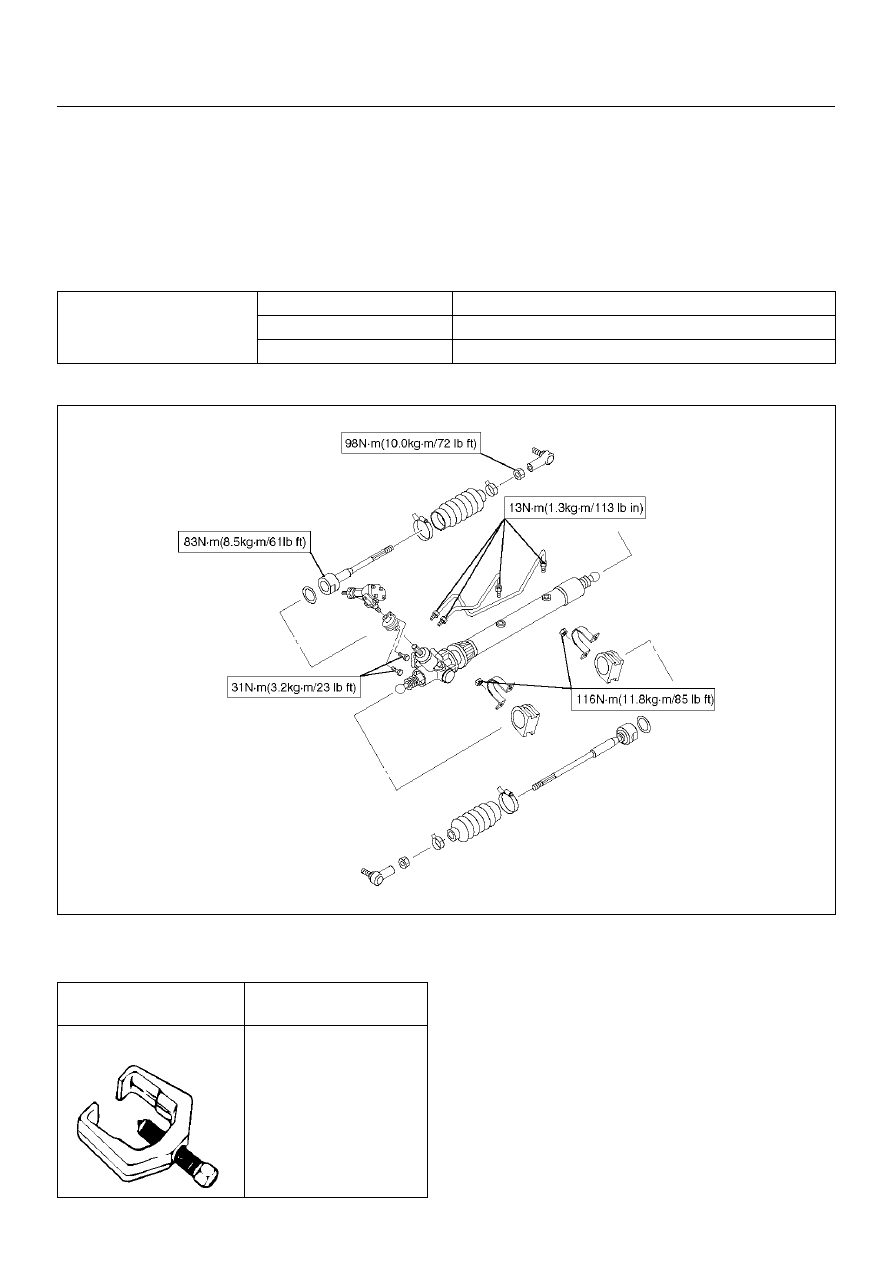

Main Data and Specifications

General Specifications

Torque Specifications

E02RX007

Special Tools

Power Steering unit

Type

Rack and pinion

Rack stroke

152mm (5.98 in)

Lock to lock

3.64

ILLUSTRATION

TOOL NO.

TOOL NAME

5–8840–2005–0

(J–29107)

Tie rod end remover