Nissan Versa Sedan. Manual - part 560

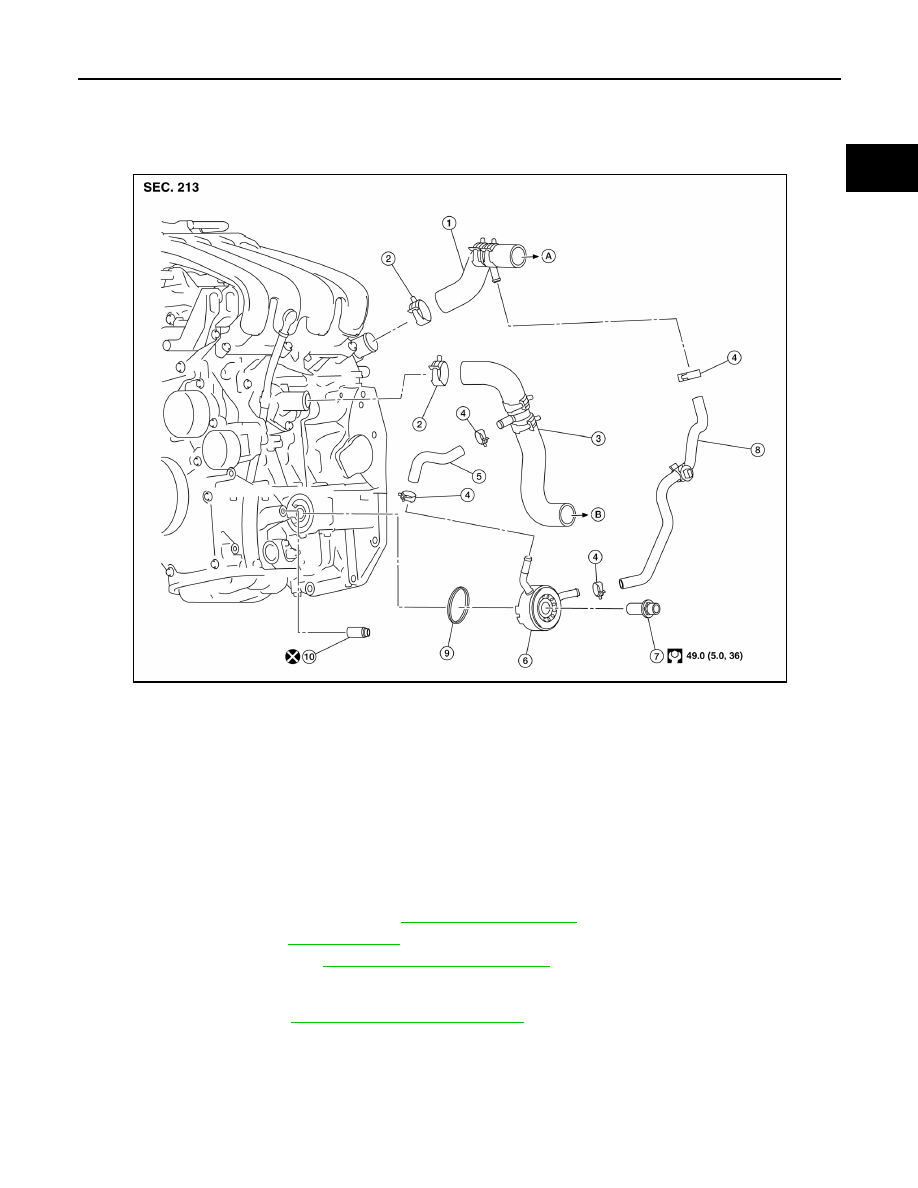

OIL COOLER

LU-15

< REMOVAL AND INSTALLATION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

OIL COOLER

Exploded View

INFOID:0000000009269704

Removal and Installation

INFOID:0000000009269705

REMOVAL

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spill-

ing.

1. Remove the engine under cover. Refer to

.

2. Drain engine oil. Refer to

.

3. Drain engine coolant. Refer to

CO-8, "Draining Engine Coolant"

.

CAUTION:

Perform when engine is cold.

4. Remove oil filter. Refer to

LU-11, "Removal and Installation"

5. Remove water hoses from the oil cooler.

6. Remove oil cooler and O-ring.

CAUTION:

Do not reuse O-rings.

INSPECTION AFTER REMOVAL

1.

Radiator hose (upper)

2.

Hose clamp

3.

Radiator hose (lower)

4.

Hose clamp

5.

Water hose

6.

Oil cooler

7.

Connector bolt

8.

Water hose

9.

O-ring

A.

To radiator (upper side)

B.

To radiator (lower side)

10. Relief valve

AWBIA1138GB