содержание .. 678 679 680 681 ..

Nissan Tiida C11. Manual - part 680

EM-72

< ON-VEHICLE REPAIR >

[HR16DE]

CAMSHAFT

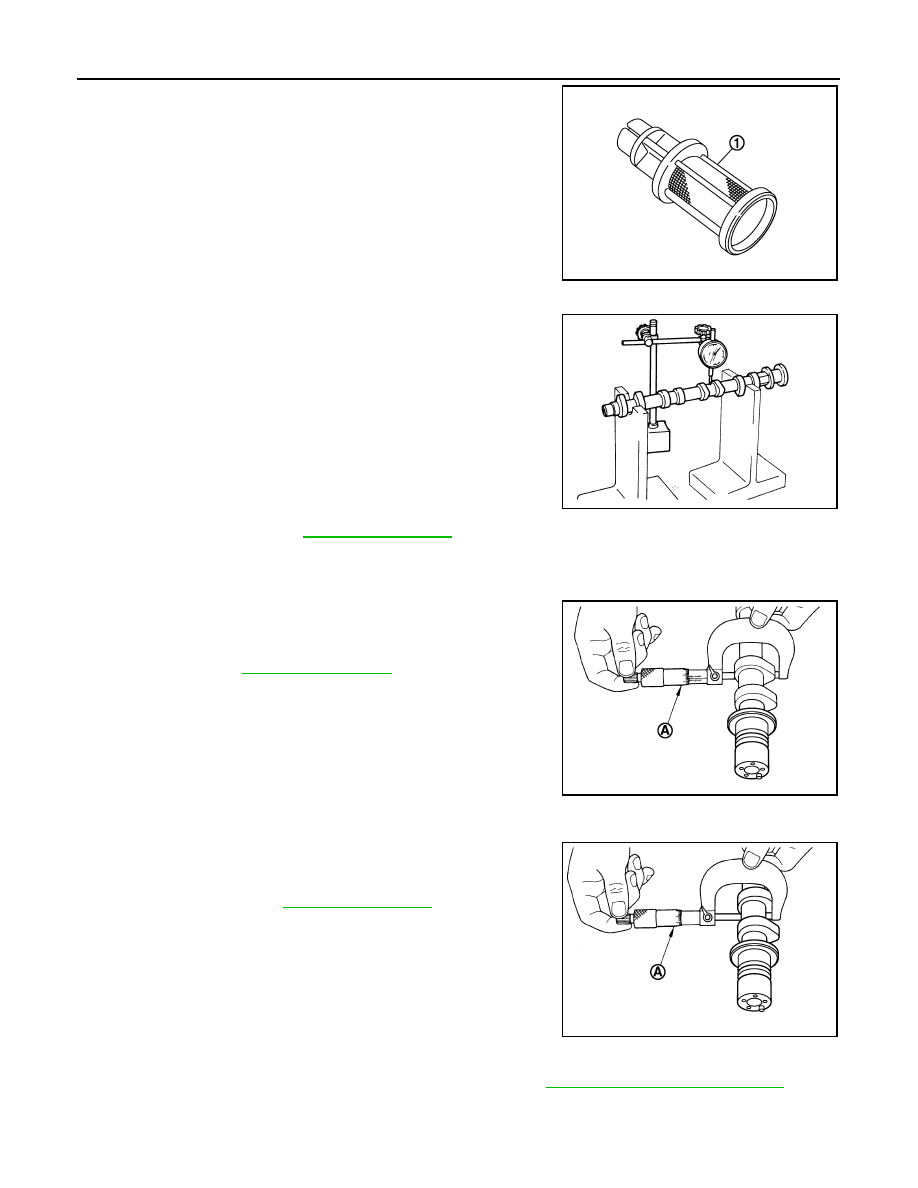

• Make sure that there is no foreign material on the oil filter (1) and

check it for clogging.

• Check the oil filter for damage.

• If there is some damage, replace the oil filter, the plug, and the

washer as a set.

Camshaft Runout

1.

Put V-block on a precise flat table, and support No. 2 and 5 jour-

nals of camshaft.

CAUTION:

Never support No. 1 journal (on the side of camshaft

sprocket) because it has a different diameter from the other

four locations.

2.

Set a dial indicator vertically to No. 3 journal.

3.

Turn camshaft to one direction with hands, and measure the

camshaft runout on the dial indicator. (Total indicator reading)

4.

If it exceeds the limit, replace camshaft.

Camshaft Cam Height

1.

Measure the camshaft cam height with a micrometer (A).

2.

If wear exceeds the limit, replace camshaft.

Camshaft Journal Oil Clearance

CAMSHAFT JOURNAL DIAMETER

Measure the outer diameter of camshaft journal with a micrometer

(A).

CAMSHAFT BRACKET INNER DIAMETER

• Tighten camshaft bracket bolts with the specified torque. Refer to

EM-59, "Removal and Installation"

.

PBIC3693E

Standard and Limit:

Refer to

.

PBIC2499E

Standard and Cam wear Limit:

PBIC3178J

Standard:

Refer to

.

PBIC3179J