содержание .. 1278 1279 1280 1281 ..

Nissan Tiida C11. Manual - part 1280

A/T FLUID

TM-171

< ON-VEHICLE MAINTENANCE >

[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

ON-VEHICLE MAINTENANCE

A/T FLUID

Checking A/T Fluid

INFOID:0000000001728293

1.

Warm up engine.

2.

Check for A/T fluid leakage.

3.

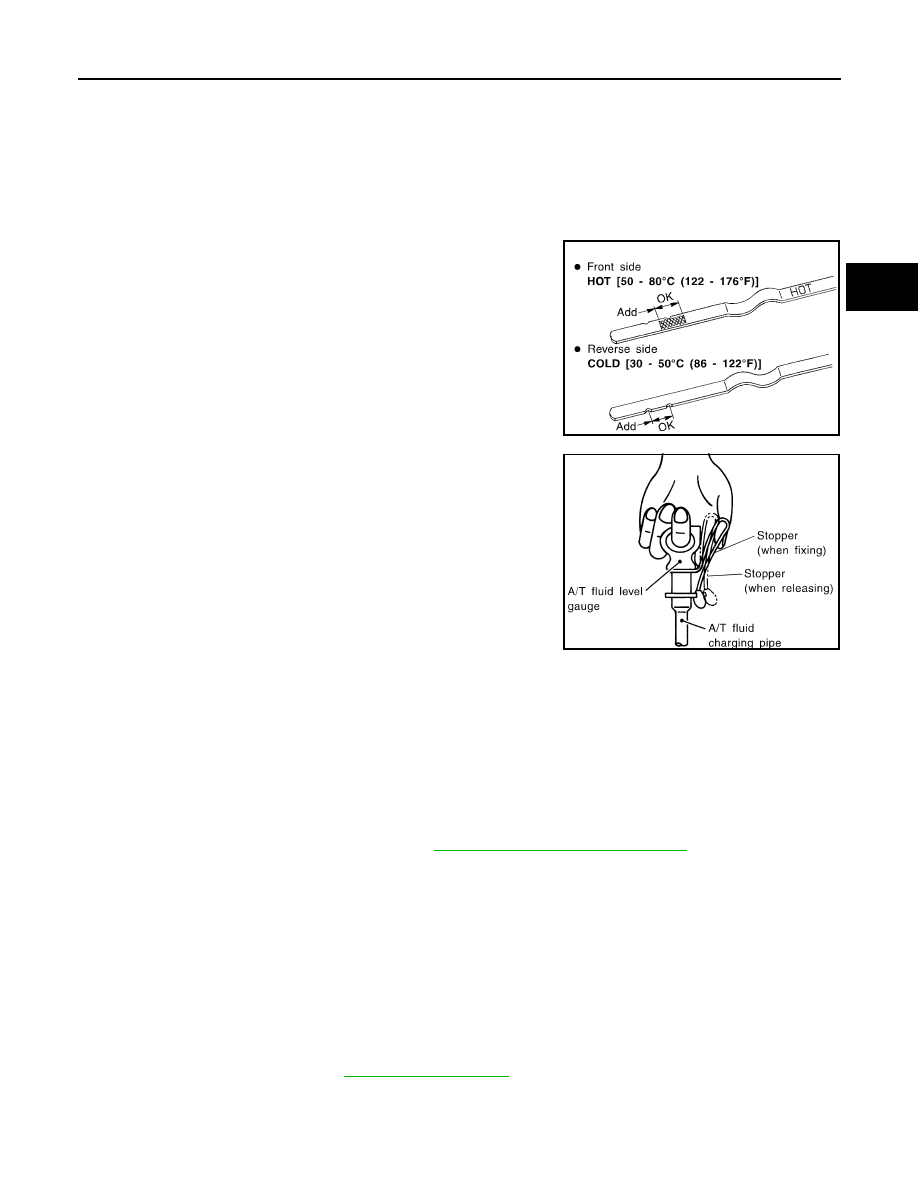

Before driving, A/T fluid level can be checked at A/T fluid tem-

peratures of 30 to 50

°

C (86 to 122

°

F) using the “COLD” range

on A/T fluid level gauge.

a.

Park vehicle on level surface and set parking brake.

b.

Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c.

Check A/T fluid level with engine idling.

d.

Remove A/T fluid level gauge and wipe clean with lint-free cloth.

CAUTION:

When wiping the A/T fluid level gauge, always use lint-free

cloth.

e.

Re-insert A/T fluid level gauge into A/T fluid charging pipe as far

as it will go.

CAUTION:

Firmly secure the A/T fluid level gauge to the A/T fluid

charging pipe using the stopper attached.

f.

Remove A/T fluid level gauge and note reading. If reading is at

low side of range, add A/T fluid to the A/T fluid charging pipe.

CAUTION:

Do not overfill.

4.

Drive vehicle for approximately 5 minutes.

5.

Re-check A/T fluid level at A/T fluid temperatures of 50 to 80

°

C (122 to 176

°

F) using “HOT” range on A/T

fluid level gauge.

CAUTION:

• When wiping the A/T fluid level gauge, always use lint-free cloth.

• Firmly secure the A/T fluid level gauge to the A/T fluid charging pipe using the stopper attached.

6.

Check A/T fluid condition and make any necessary repairs. If the A/T fluid smells burnt, contains frictional

material (clutches, bands, etc.), or if the A/T is repaired, overhauled, or replaced, inspect and clean the A/

T fluid cooler mounted in the radiator. Refer to

TM-172, "A/T Fluid Cooler Cleaning"

.

7.

Install the removed A/T fluid level gauge into the A/T fluid charging pipe.

CAUTION:

Firmly secure the A/T fluid level gauge to the A/T fluid charging pipe using the stopper attached.

Changing A/T Fluid

INFOID:0000000001728294

1.

Warm up A/T fluid.

2.

Stop engine.

3.

Drain A/T fluid by removing the drain plug from the transaxle.

4.

Reinstall the drain plug and new gasket and tighten to the specified torque.

CAUTION:

Do not reuse drain plug gasket.

SCIA3451E

SMA051D

Drain plug:

.