LG936L Wheel Loader. Manual - part 8

Operation & Maintenance Manual──LG936L Wheel Loader

28

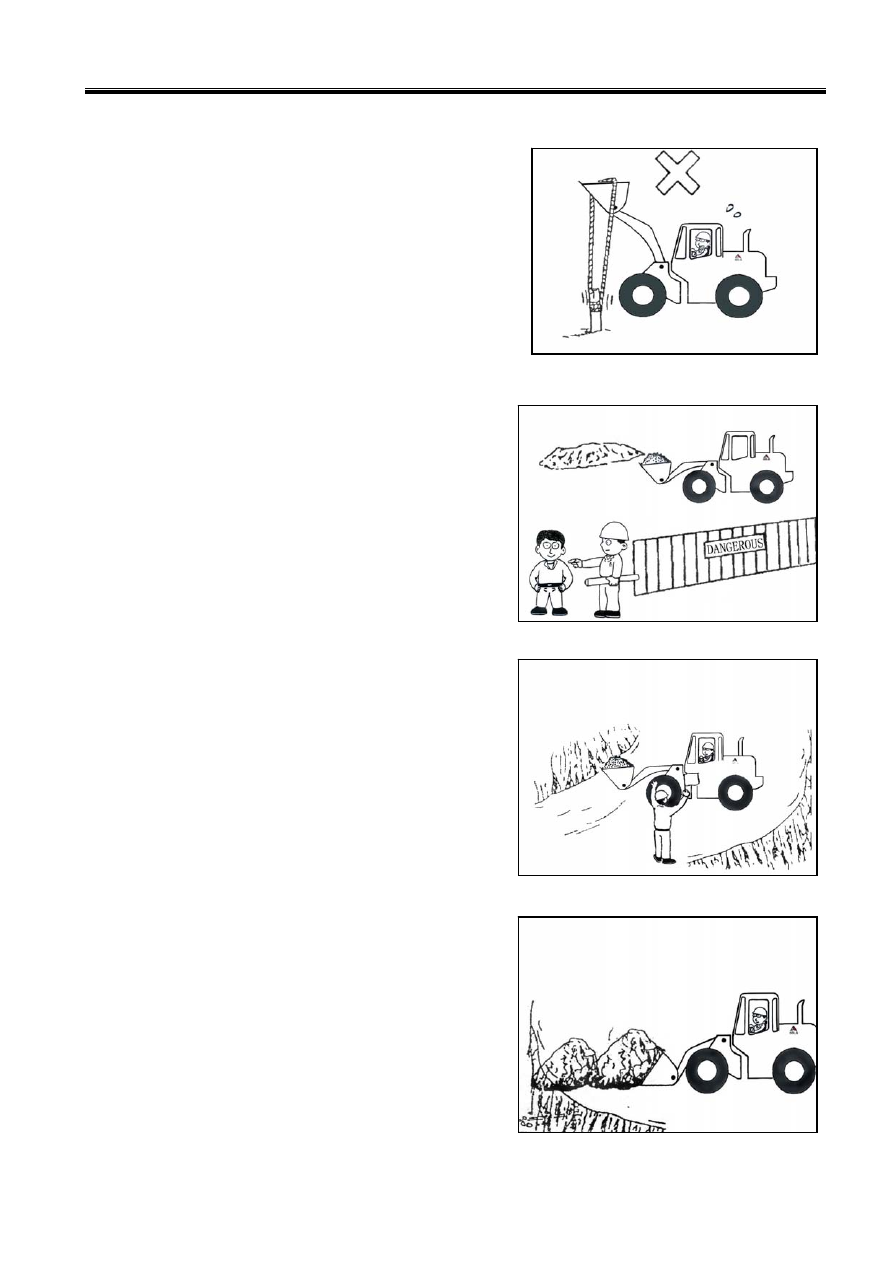

z Don’t use the machine for any work other than what

the machine is designed for. It may damage the parts

or cause an accident when using the head of the

working equipment for other fuctions, such as hook,

grasp, draw, push, or tow.

6.2 Pay Attention to Surroundings

z No unauthorized person is allowed to enter the

working area because the working equipment will

work up and down, turn left and right and move

forward and backward all the time. Keep people

away from all sides of the working equipment.

z To ensure safety when working at the side of a road

or hear a cliff where the land may shift, designate a

person to watch and direct at all times.

z Take care with the dumping position when unloading

sand or rocks from the high position.

z When pushing material off a cliff or when the

highest point is reached, the load may desrease

suddenly. Subsequently, the moving speed will

increase, so slow down in advance.

z When constructing a dam or unloading soil from a

cliff, form one pile first and use the second pile to

push the first one.