Mitsubishi L200. Manual - part 20

ON-VEHICLE SERVICE

ENGINE MECHANICAL

11A-8

CAUTION

• The temperature of the surface of the belt

should be as close to normal temperature as

possible.

• Do not let any contaminants such as water or

oil get onto the microphone.

• If strong gusts of wind blow against the

microphone or if there are any loud sources

of noise nearby, the values measured by the

microphone may not correspond to actual

values.

• If the microphone is touching the belt while

the measurement is being made, the values

measured by the microphone may not corre-

spond to actual values.

• Do not take the measurement while the vehi-

cle's engine is running.

AC903689

15˚

15˚

MB992080

(Microphone)

10 – 15 mm

AB

Tensioner pulley

Crankshaft

pulley

A/C compressor pulley

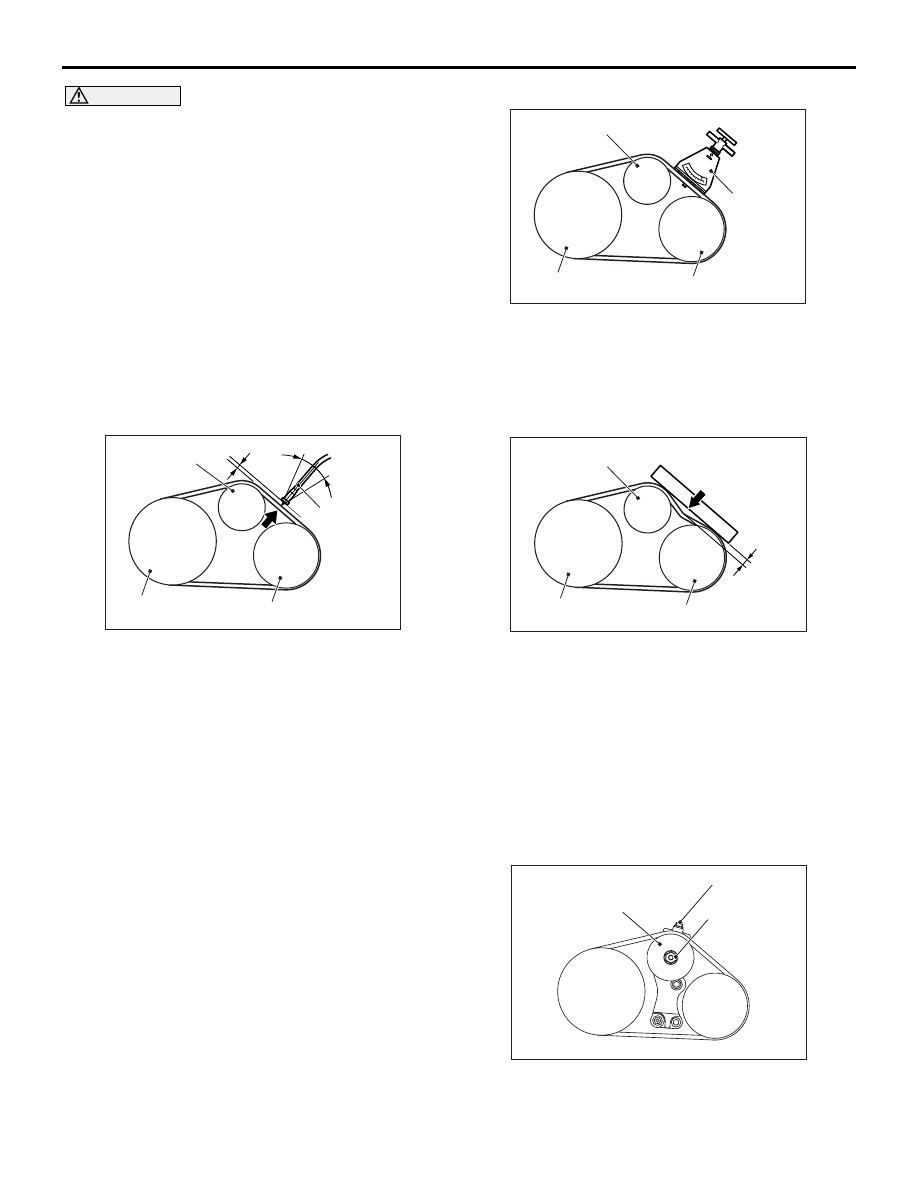

5. Hold special tool MB992080 to the middle of the

belt between the pulleys (at the place indicated by

arrow) where it does not contact the belt

(approximately 10

− 15 mm away from the rear

surface of the belt) so that it is perpendicular to

the belt (within an angle of

± 15 °).

6. Press the "MEASURE" button.

7. Gently tap the middle of the belt between the

pulleys (the place indicated by the arrow) with

your finger as shown in the illustration, and check

that the vibration frequency of the belt is within the

standard value.

NOTE: To take the measurement repeatedly, fillip

the belt again.

WHEN USING THE TENSION GAUGE

AC506003AB

Tensioner pulley

Crankshaft

pulley

A/C compressor pulley

Tension

gauge

Use a belt tension gauge in the middle of the belt

between the pulleys shown in the figure (at the place

indicated by the arrow) to check that the belt tension

is within the standard value.

BELT DEFLECTION CHECK

AC506004AB

Tensioner pulley

Crankshaft

pulley

A/C compressor pulley

Approximately

100N

Deflection

Apply approximately 100 N of pressure against the

location between the pulleys shown by the arrow in

the illustration and then measure the deflection.

When the belt tension is adjusted by measuring the

belt deflection, adjust it with a tool for vibration fre-

quency measurement or tension measurement after-

ward.

BELT TENSION ADJUSTMENT

If not within the standard value, adjust the belt ten-

sion by the following procedure.

AC505988AB

Adjusting bolt

Locking nut

Tensioner pulley

1. Loosen the locking nut of the tensioner pulley.