Mitsubishi L200. Manual - part 12

PRECAUTIONS BEFORE SERVICE

GENERAL

00-44

For this reason, when the injector or engine-ECU is

replaced, injector correction data must be registered

afterwards in the engine-ECU using the Multi Use

Tester III (M.U.T.-III).

Correction data is converted into an identification

code consisting of 30 alphanumeric characters and

printed on the injector connector.

REGISTRATION PROCEDURE

1. When replacing the engine-ECU, connect the

current engine-ECU to the body harness.

NOTE: This operation is purposed to read the injec-

tor identification code stored in the engine-ECU.

Reading the identification code in this way before

replacement can eliminate manual input of the identi-

fication code after replacement.

2. After the ignition switch is in "LOCK" (OFF)

position, connect the M.U.T.-III to the diagnosis

connector.

3. Turn the ignition switch to "ON" position.

4. Select SPECIAL FUNCTION from the function

menu.

5. When the current engine-ECU is still mounted,

read and register the injector identification code

as follows:

(1) Select Read Injector ID Code (for engine-ECU

replacement) from the SPECIAL FUNCTION

menu.

(2) Select Write and Save Injector ID Code from

the menu to read data from the current engine-

ECU and save the data if it could be read

normally.

(3) Mount the new engine-ECU on the vehicle.

(4) Select SPECIAL FUNCTION from the function

menu.

(5) Select Write Injector ID Code (for engine-ECU

replacement) from the SPECIAL FUNCTION

menu.

(6) Select SAVED INJECTOR ID WRITING from

the Write Injector ID Code menu to write the

data, which was saved previously, to the

engine-ECU.

6. If the injector has been replaced or data has not

been read from the current engine-ECU, register

the injector identification code as follows:

(1) Select Write Injector ID Code from the

SPECIAL FUNCTION menu.

(2) If the injector was replaced, specify whether to

write to every cylinder or a specific cylinder.

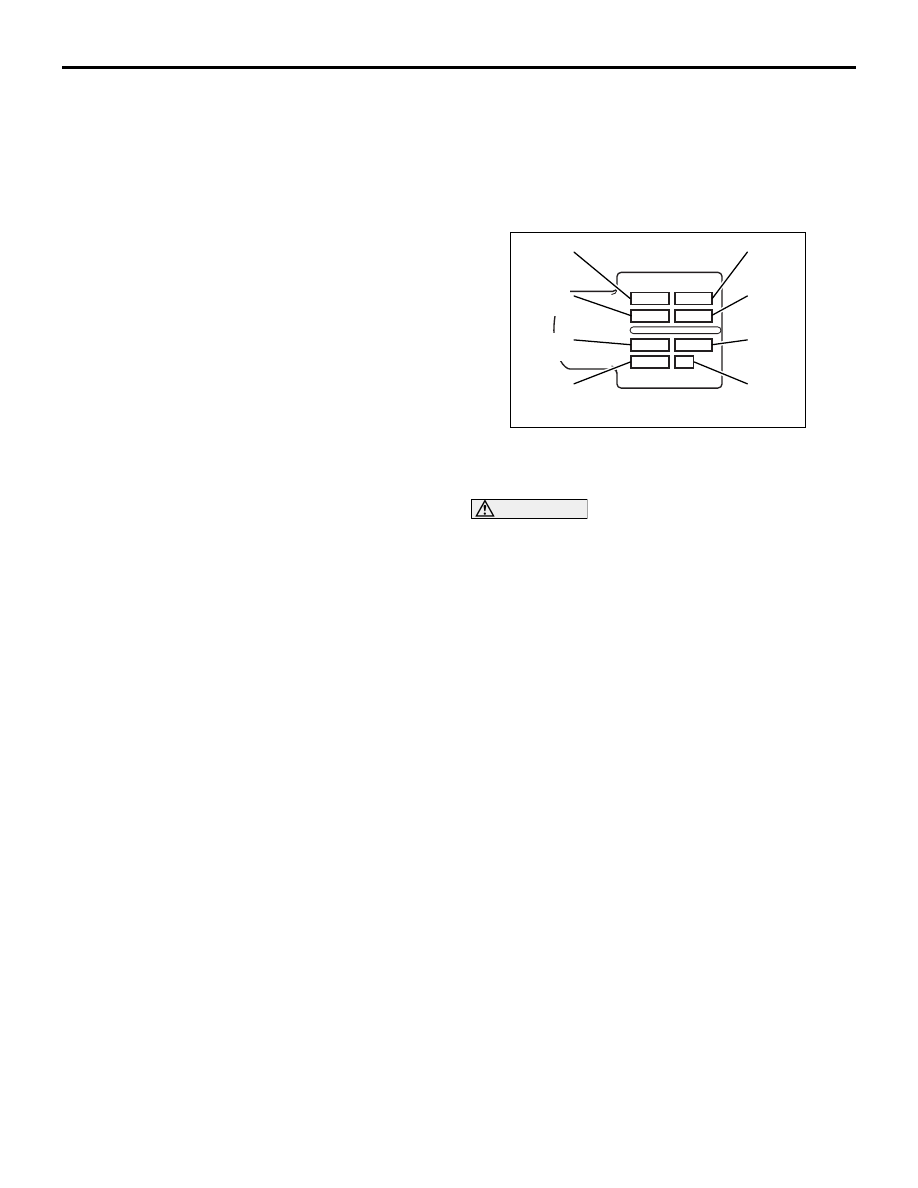

AK501492

Frame 1

(4 digits)

Frame 3

(4 digits)

Frame 5

(4 digits)

Frame 7

(4 digits)

Frame 2

(4 digits)

Frame 4

(4 digits)

Frame 6

(4 digits)

Frame 8

(2 digits)

AB

(3) Select the write mode from the menu, enter

the identification code printed on the injector,

and execute writing.

CAUTION

Even if the number of the cylinder to be regis-

tered does not match the actual injector mount-

ing location, registration ends normally. Specify

the cylinder number correctly.

NOTE: The identification code is displayed in order

of the frame numbers when it is read.

7. Makes sure that the engine warning lamp that is

on changes to blinking, indicating the registration

is complete.

NOTE: When the injector is replaced, executing the

write operation also clears the values of small injec-

tion quantity learning.

8. Execute small injection quantity learning.

Refer to

, the SMALL INJECTION

QUANTITY LEARNING PROCEDURE for the

learning procedure.

9. Confirm that the engine warning lamp is off.

Confirm also that the diagnosis code is not stored.