Mazda 6. Manual - part 222

TROUBLESHOOTING

K–129

K

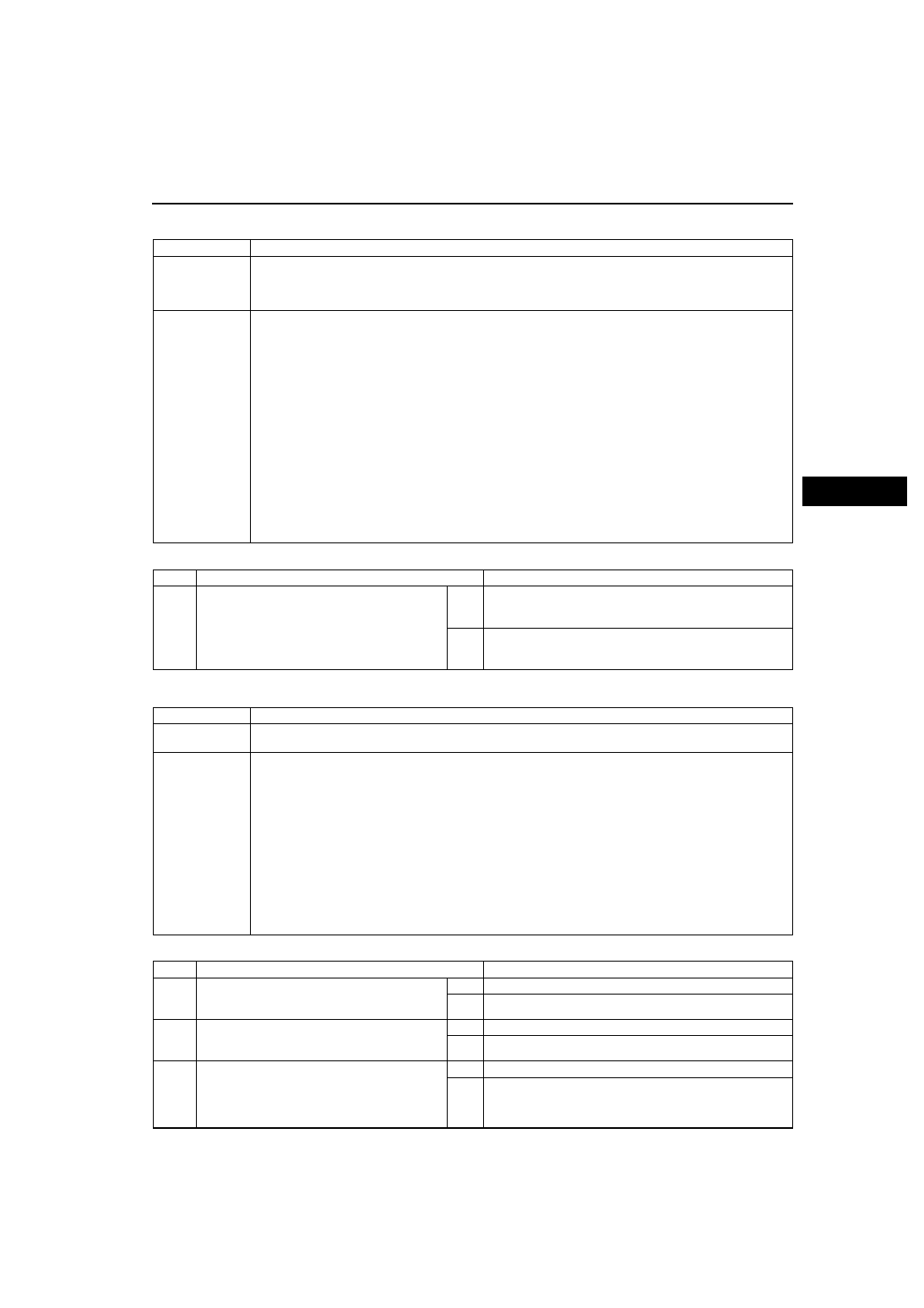

NO.22 NO ENGINE BRAKING IN HOLD MODE

A6E568001030W26

Diagnostic procedure

End Of Sie

NO.23 TRANSAXLE OVERHEATS

A6E568001030W27

Diagnostic procedure

22

No engine braking in hold mode

DESCRIPTION

• Engine speed drops to idle but vehicle coasts when accelerator pedal is released during cruising at

medium to high speeds.

• Engine speed drops to idle but vehicle coasts when accelerator pedal is released when in L range at

low vehicle speed.

POSSIBLE

CAUSE

1. Clutch slippage, burned (low and reverse brake)

• Line pressure low

• Shift solenoid D malfunction

• Shift solenoid E malfunction

• Shift solenoid C malfunction

• Control valve body malfunction

• Body GND malfunction

2. Signal malfunction

• TP sensor malfunction

• Vehicle speed sensor malfunction

• Sensor GND malfunction

• Input/turbine speed sensor malfunction

3. HOLD switch ON not judged by PCM (short, or open circuit, poor operation)

• HOLD switch signal malfunction

Note

• Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP

INSPECTION

ACTION

1

• Do following symptoms concurrently occur?

— Engine flares up or slips during

acceleration.

— Engine flares up or slips when shifting.

Yes

Go to symptom troubleshooting NO.14 "Engine flares up or

slips when upshifting or downshifting" or No.15 "Engine

flares up or slips when accelerating vehicle".

No

Repeat basic inspection and repair or replace any defective

parts according to inspection result.

(See

23

Transaxle overheats

DESCRIPTION

• Burnt smell emitted from transaxle.

• Smoke emitted from transaxle.

POSSIBLE

CAUSE

• The malfunction is restricted to hindrance of coolant at the oil cooler. In addition, overheating of the

transaxle may be caused by a malfunction of the transaxle fluid temperature sensor.

1. Burned (TCC)

• Line pressure low

• Control valve body malfunction

• Accelerator cable misadjustment

2. Oil cooler malfunction (Foreign material mixed ATF)

3. Transaxle fluid temperature sensor malfunction

4. Excessive amount of ATF

5. Torque converter malfunction

Note

• Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP

INSPECTION

ACTION

1

• Inspect for bent, damage, corrosion or kinks

of oil cooler pipes.

• Are oil cooler pipes okay?

Yes

Go to next step.

No

Replace any defective parts.

2

• Perform the stall test.

(See

• Is stall speed okay?

Yes

Go to next step.

No

Repair or replace any defective parts.

3

• Check the value at the following PID using

the WDS or equivalent.

(See

— TP

• Is PID value okay?

Yes

Go to next step.

No

Repair or replace any defective parts.