Mazda 6. Manual - part 221

TROUBLESHOOTING

K–125

K

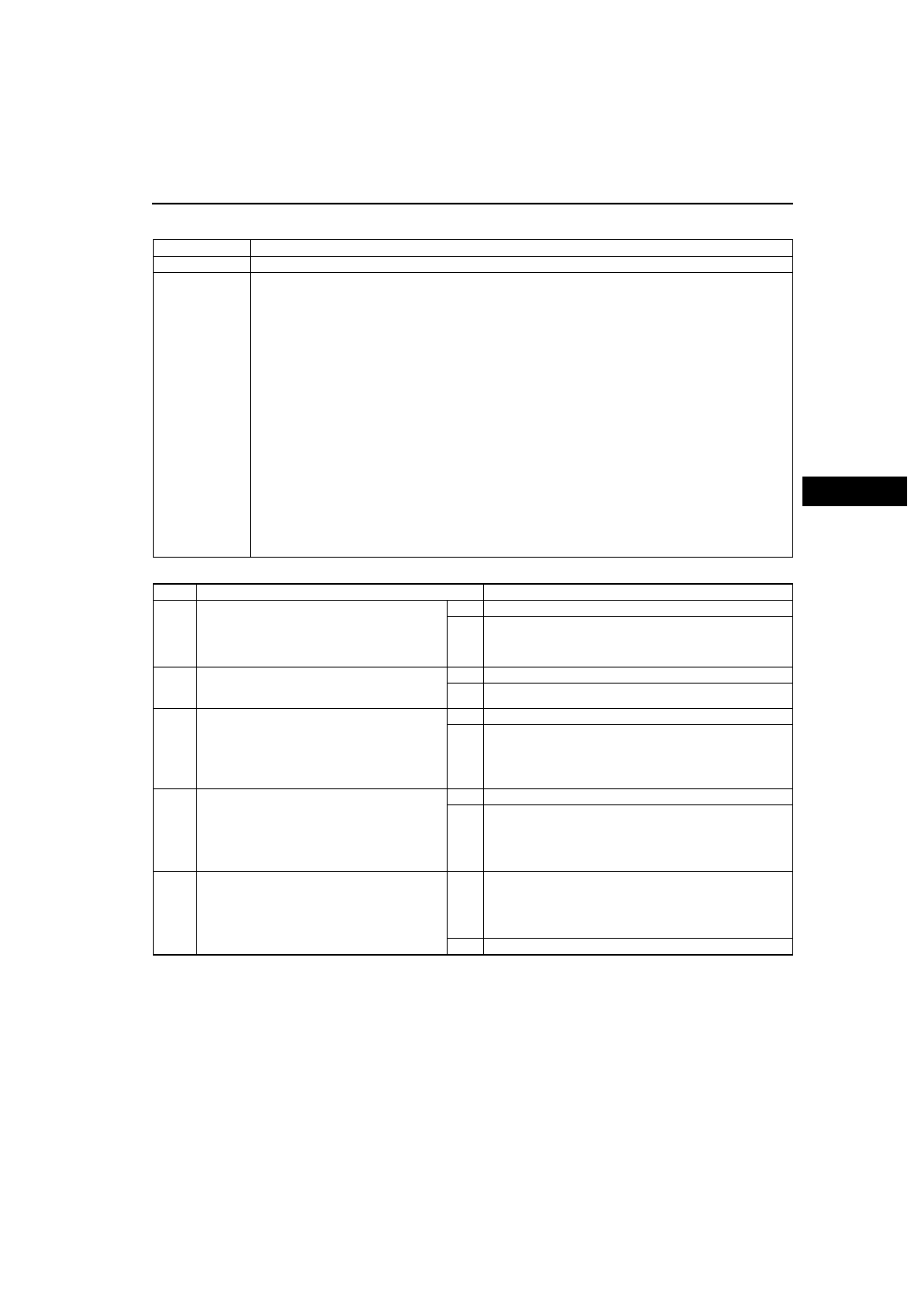

NO.16 JUDDER UPON TORQUE CONVERTER CLUTCH (TCC) OPERATION

A6E568001030W20

Diagnostic procedure

End Of Sie

16

Judder upon torque converter clutch (TCC) operation

DESCRIPTION

• Vehicle jolts when TCC is engaged.

POSSIBLE

CAUSE

• Poor TCC engagement due to either slippage because the TCC is stuck or the line pressure is low

Caution

• If the TCC is stuck, inspect it. In addition, inspect the oil cooler for foreign particles which

may have mixed in with the ATF.

1. Torque converter clutch piston slipped, burned

• Line pressure high

• Shift solenoid A malfunction

• Control valve body malfunction

• Body GND malfunction

• Pressure control solenoid malfunction

2. Signal malfunction

• Vehicle speed sensor malfunction

• Sensor GND malfunction

• TFT sensor malfunction

• TP sensor malfunction or mis-adjustment

• Input/turbine speed sensor malfunction

3. Torque converter malfunction

Note

• Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP

INSPECTION

ACTION

1

Check the value at the following PIDs using the

WDS or equivalent. (See

• TSS

Are PID values okay?

Yes

Go to next step.

No

Repair or replace any defective parts.

2

Disconnect PCM. Is resistance between ground

terminal at PCM connector and body ground

less than 5.0 ohms?

Yes

Go to next step.

No

Repair open ground circuit.

3

Check resistance between shift solenoid A

control circuit at PCM connector and control

valve body connector. Check resistance

between shift solenoid A circuit at PCM

connector and control valve body connector. Are

the resistance less than 5.0 ohms?

Yes

Go to next step.

No

Repair shift solenoid A circuit.

4

Inspect Shfit solenoid. (See

.) Is the solenoid valve

operating properly?

Yes

Go to next step.

No

Overhaul control valve body and repair or replace any

defective parts. If problem remains, overhaul transaxle and

repair or replace any defective parts. (See ATX workshop

manual (FN4A-EL) [1623-10-98E].) (See ATX workshop

manual supplement (FN4A-EL) [1746-1*-02C].)

5

Check LPS PID value.

Is LPS PID value okay?

(See

Yes

Overhaul control valve body and repair or replace any

defective parts. If problem remains, overhaul transaxle and

repair or replace any defective parts. (See ATX workshop

manual (FN4A-EL) [1623-10-98E].) (See ATX workshop

manual supplement (FN4A-EL) [1746-1*-02C].)

No

Replace PCM.