Mazda 6. Manual - part 163

F–174

ON-BOARD DIAGNOSTIC

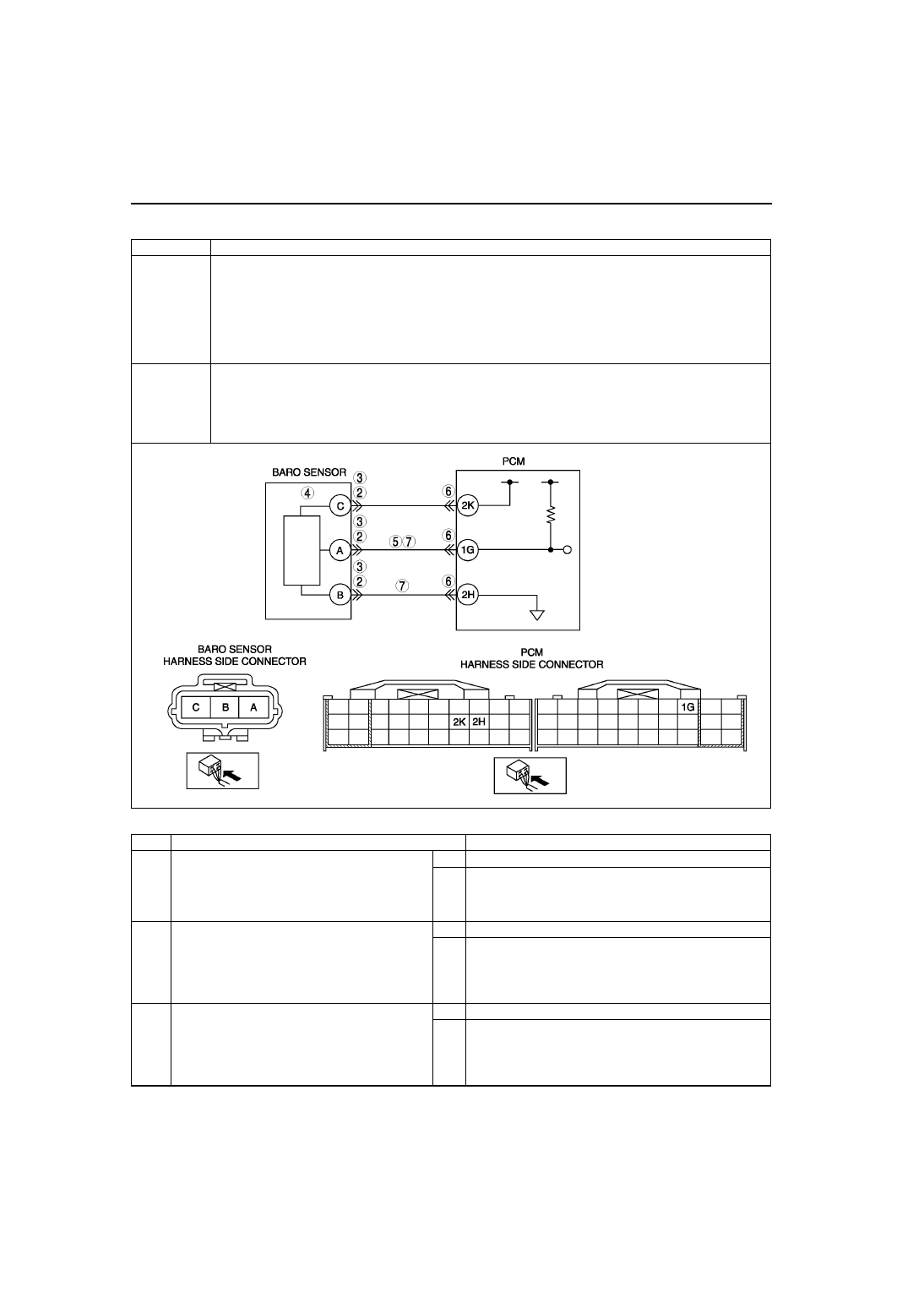

DTC P2229

A6E397001083W07

Diagnostic procedure

DTC P2229

BARO sensor circuit high input

DETECTION

CONDITION

• PCM monitors input voltage from BARO sensor. If input voltage at PCM terminal 1G is above 4.92 V, PCM

determines that BARO sensor circuit has malfunction.

Diagnostic support note

• This is a continuous monitor (CCM).

• MIL illuminates if PCM detects the above malfunction condition during first drive cycle.

• PENDING CODE is available if PCM detects the above malfunction condition.

• FREEZE FRAME DATA is available.

• DTC is stored in PCM memory.

POSSIBLE

CAUSE

• BARO sensor malfunction

• Connector or terminal malfunction

• Open circuit in wiring between BARO sensor terminal A and PCM terminal 1G

• Open circuit in wiring between BARO sensor terminal B and PCM terminal 2H

• Short to power circuit in wiring between BARO sensor terminal A and PCM terminal 1G

• PCM malfunction

STEP

INSPECTION

ACTION

1

PERFORM DTC CONFIRMATION PROCEDURE

• Perform DTC CONFIRMATION PROCEDURE.

.)

• Is same DTC present?

Yes Go to next step.

No

Intermittent concern exists. Go to INTERMITTENT

CONCERN TROUBLESHOOTING procedure.

(See

2

INSPECT CONNECTION OF BARO SENSOR

CONNECTOR

• Turn ignition key to OFF.

• Verify that BARO sensor connector is

connected securely.

• Is connection okay?

Yes Go to next step.

No

Reconnect the connector, then go to Step 8.

3

INSPECT BARO SENSOR CONNECTOR FOR

POOR CONNECTION

• Disconnect the BARO sensor connector.

• Inspect for poor connection (damaged/pulled-

out pins, corrosion, etc.).

• Is there malfunction?

Yes Repair or replace suspected terminal, then go to Step 8.

No

Go to next step.