Iveco Daily. Manual - part 15

ENGINES 8140.43R/B/S/N

42

D

AILY

Base - May 2004

8140.43R.43XX

8140.43R.44XX

ID/TCA

8140.43B.43XX

8140.43B.44XX

ID/TCA

8140.43S.41XX

8140.43S.43XX

8140.43S.44XX

ID/TCA

8140.43N.43XX

8140.43N.44XX

ID/TCA

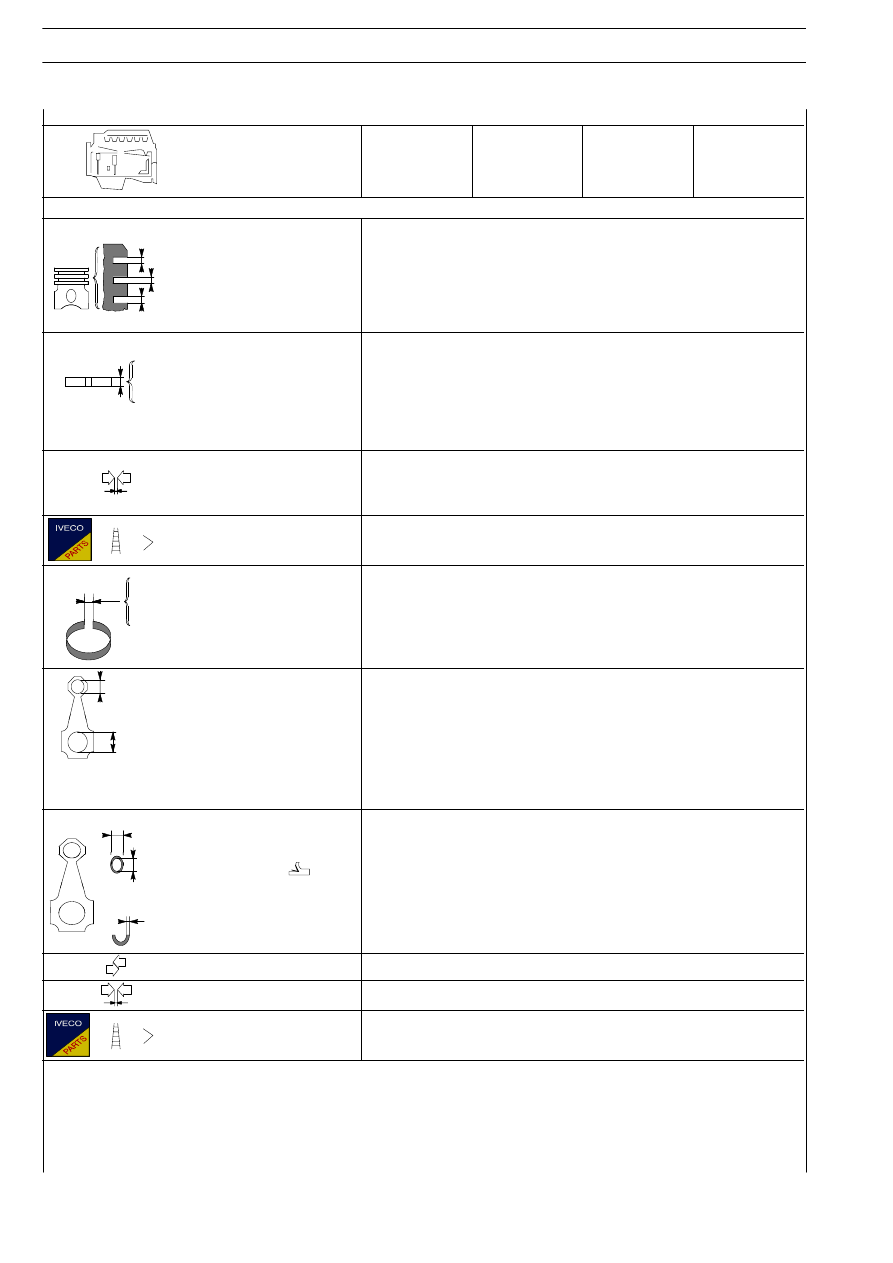

CYLINDER BLOCK AND CRANK MECHANISM COMPONENTS

mm

Piston type

MONDIAL PISTON - KS

1

X

X1*

2.200

÷ 2.230

X

1

2

X

Piston ring grooves

X2

2.050

÷ 2.070

X

3

2

X

X3

2.540

÷ 2.560

3

X

* measured on

∅ of 91.4 mm

1

S

S 1*

2.068

÷ 2.097

1

2

S

S

Piston rings

S 2

1.970

÷ 1.995

3

2

S

S

S 3

2.470

÷ 2.490

* measured on

∅ of 91.4 mm

1

0.103

÷ 0.162

Piston rings - grooves

2

0.55

÷ 0.100

3

0.05

÷ 0.09

Piston rings

0.4

X1

2

X

Piston ring end gap in cylin-

der liners

3

2

X

X

X1

0.20

÷ 0.35

3

X

X2

0.30

÷ 0.50

X3

0.30

÷ 0.55

1

∅

Small end bush housing

Ø 1

35.460

÷ 35.490

∅ 2

Big end bearing housing *

Ø 2

60.341

÷ 60.348

* spare connecting rod

supplied

∅4

Small end bush diameter

∅

outside

∅ 4

35.570

÷ 35.595

∅3

inside

∅ 3

32.010

÷ 32.020

SS

Big end bearing shell

supplied as spare parts

S

1.875

÷ 1.884

Small end bush - housing

0.08

÷ 0.135

Piston pin - bush

0.014

÷ 0.03

Piston rings

0.254

÷ 0.508