Isuzu engine C22NE / 22LE / 20LE. Manual - part 20

6A-62 ENGINE MECHANICAL (C22NE, 22LE, 20LE)

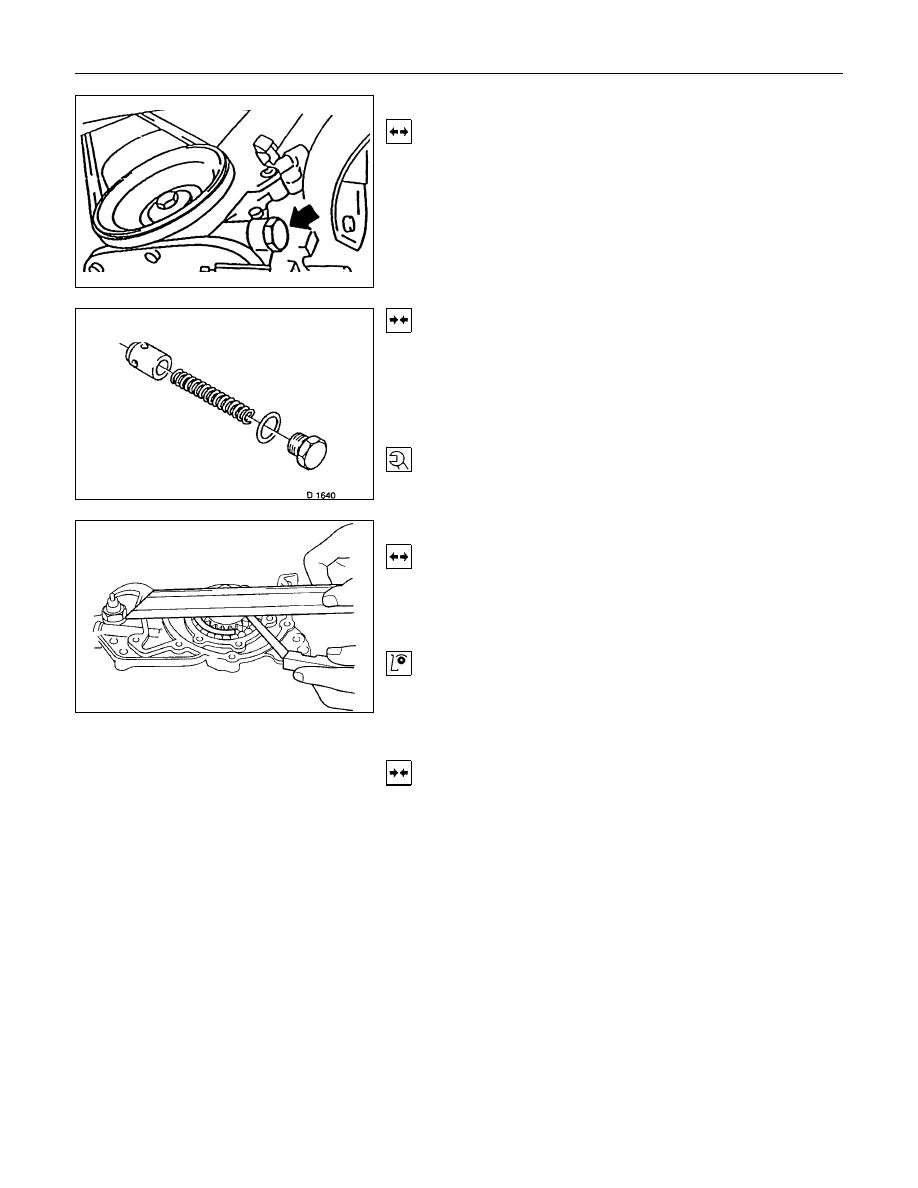

Oil Pump Safety Valve

Removal

1.

Remove closure plug.

2.

Remove seal ring.

3.

Remove spring.

4.

Remove piston.

Installation

1.

Install piston (observe installation position).

2.

Install spring.

3.

Install seal ring.

4.

Install closure plug.

Tighten (Torque)

Closure plug - 30 N

⋅

m (3.0 kgf

⋅

m)

Oil Pump (Overhaul)

Removal

1.

Remove oil pump according to the corresponding

operation.

2.

Remove oil cover and pressure control valve.

Inspect

Clearance between gear pair and housing upper edge - see

“Technical Data”.

Check housing, cover and pressure control valve.

Installation

1.

Install pump cover with Sealing Compound 15 03 166 (90

094 714).

2.

Install oil pump safety valve according to the

corresponding operation.

3.

Install oil pump according to the corresponding operation.