Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 953

REAR AXLE 4B-49

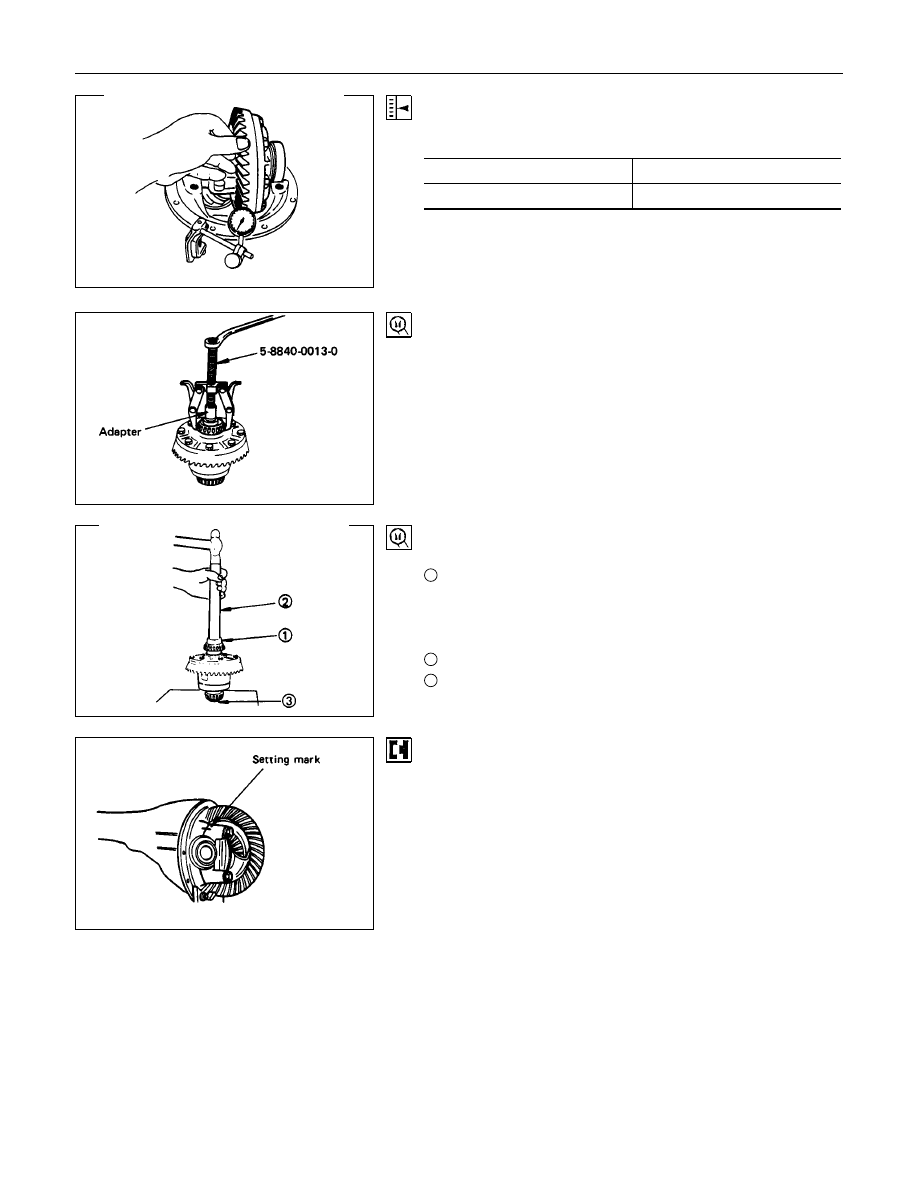

(4) Adjust the feeler gauge thickness from side to side until the

ring gear backlash is in the specified range.

Backlash

mm(in)

194 mm

0.13 - 0.18 (0.005 - 0.007)

220 mm

0.15 - 0.20 (0.006 - 0.008)

With zero end play and correct backlash established, remove

feeler gauge packs, determine the thickness of shims required

and add 0.05 mm (0.002 in.) to each shim pack to provide side

bearing preload. Always use new shims.

(5) Remove side bearing

Remover : 5-8840-0013-0

(J-22888)

Adapter

: 9-8521-1743-0 (194 mm)

(J-8107-2)

: 5-8840-2196-0 (220 mm)

(J-8107-4)

12.Side Bearing

Install side bearings together with selected shims.

1

Installer

: 9-8522-1164-0 (194 mm)

(J-24244)

: 5-8840-2162-0 (220 mm)

(J-37257)

2

Drive handle : 5-8840-0007-0 (J-8092)

3

Pilot

: 9-8521-1743-0 (J-8107-2)

15.Bearing Cap

Align the setting marks applied at the time of disassembly.