Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 795

6A–60

ENGINE MECHANICAL (6VD1 3.2L)

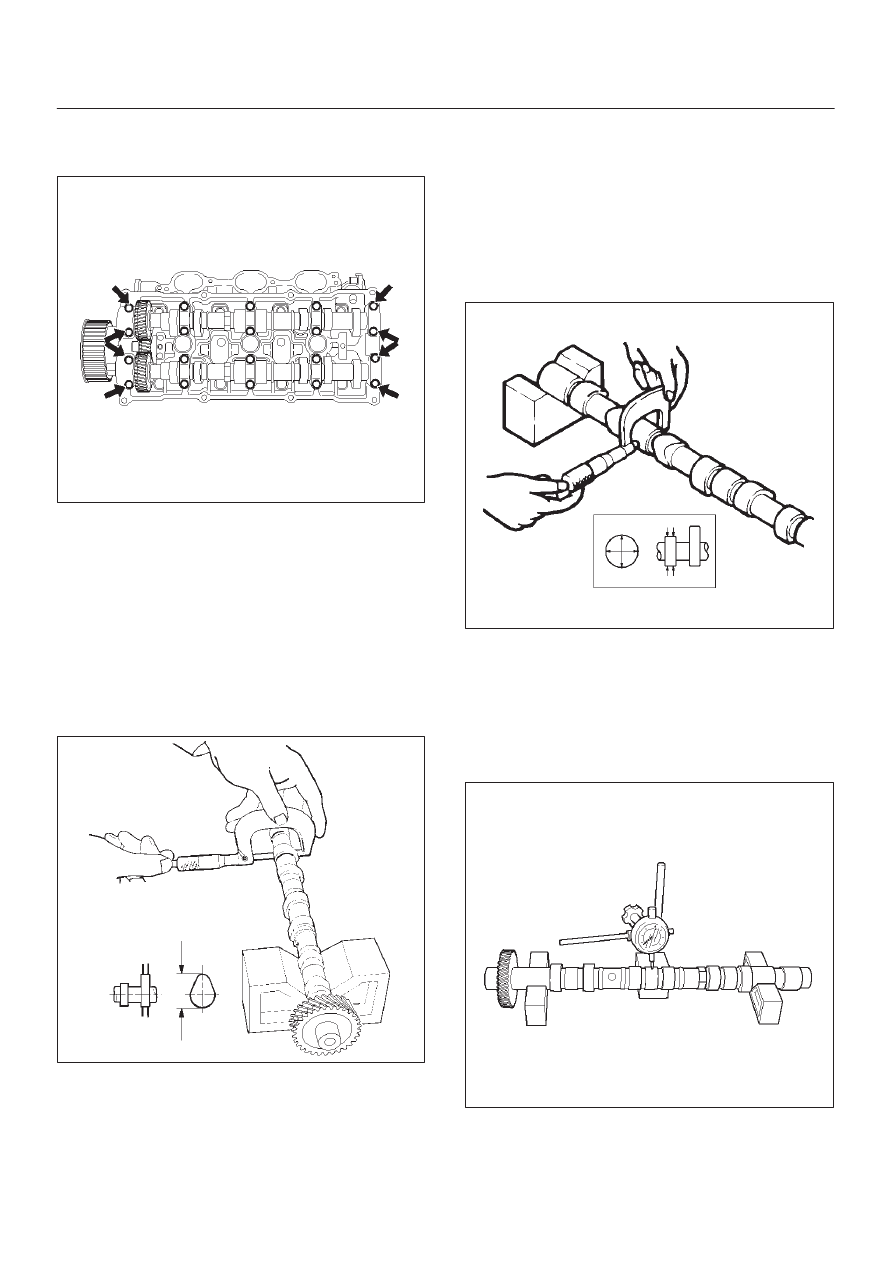

2. Remove twenty fixing bolts from inlet and exhaust

camshaft bracket on one side bank, then camshaft

brackets (2).

014RW027

3. Remove camshaft assembly (3), (4).

4. Remove three fixing bolts (7) from camshaft drive

gear retainer (8), then camshaft drive gear assembly.

Inspection and Repair

1. Use a micrometer to measure the cam lobe height

and uneven wear. Replace the camshaft if either the

lobe height or the uneven wear exceeds the specified

limit.

Lobe height : 44.709 mm (1.7602 in)

Uneven wear : 0.05 mm (0.0020 in)

014RW043

2. Use a micrometer to measure the diameter and the

uneven wear of the camshaft journals.

Replace the camshaft if the diameter or the uneven

wear exceeds the specified limit.

Journal Diameter

Standard : 25.972 mm–25.993 mm

(1.0225 in–1.0233 in)

Limit : 25.8 mm (1.0157 in)

Uneven wear : 0.05 mm (0.0020 in)

014RS023

3. Place the camshaft on V–blocks.

Slowly rotate the camshaft and measure the runout

with a dial indicator.

Replace the camshaft if the runout exceeds the

specified limit.

Run out

Limit : 0.1 mm (0.0039 in)

014RW044