Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 246

ENGINE DRIVEABILITY AND EMISSIONS

6E–225

ENGINE CRANKS BUT WILL NOT RUN

DEFINITIONS: Engine cranks, but will not run. (The engine never start.)

NOTE: The replacement ECM must be programmed. Refer to section of the Service Programming System (SPS) in

this manual. Following ECM programming, the immobiliser system (if equipped) must be linked to the ECM.

Refer to section 11 “Immobiliser System-ECM replacement” for the ECM/Immobiliser linking procedure.

NOTE: The vehicle with immobiliser system, this system may be activated. Check the immobiliser system diagosis.

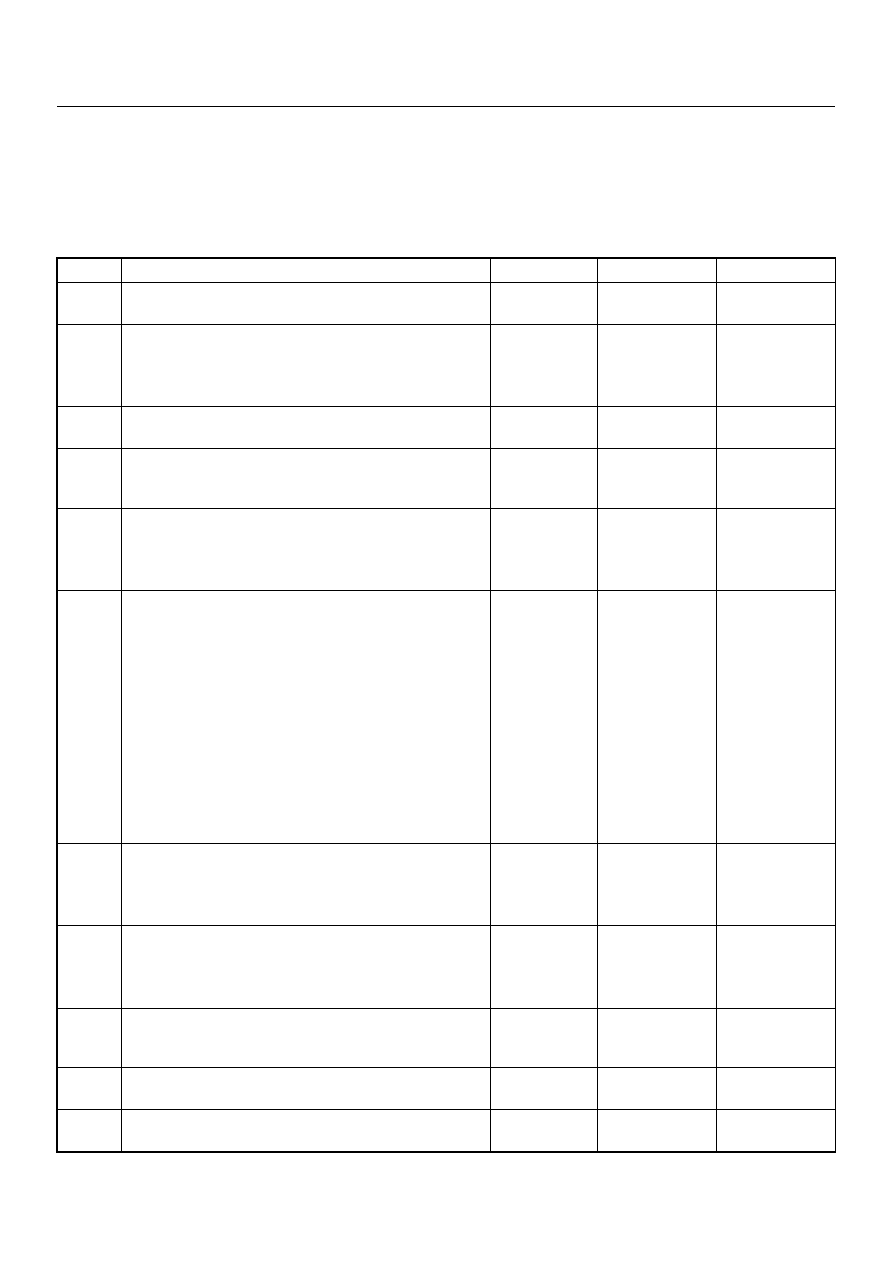

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to OBD

System Check

2

1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—

Verify repair

Go to Step 3

3

Was a visually/physical check performed?

—

Go to Step 4

Go to Visual /

physical Check.

4

Check the “Ignition coil” fuse (15A) and “ECM” fuse

(15A).

Was a fuse blown?

—

Verify repair

Go to Step 5

5

1. Ignition ON

2. Use a DVM to verify that battery voltage at the

ignition coil fuse, and the ECM fuse.

Was battery voltage presented at the fuses?

—

Go to Step 6

Verify & repair

6

1. Visually/physically inspect for the following

conditions:

• Restriction of air intake system. Check for a

restricted air filter element, or foreign objects

blocking the air intake system.

• Check for objects blocking the IAC passage or

throttle bore, excessive deposits in the throttle

bore and on the throttle plate.

• Check for a condition that causes a large

vacuum leak, such as an incorrectly installed or

faulty crankcase ventilation hose/brake booster

hose.

Was a problem found?

—

Verify repair

Go to Step 7

7

1. Using a Tech 2, display the IAC value.

2. Check for a faulty, plugged, or sticking IAC

operation.

Was the problem found?

—

Verify repair

Go to Step 8

8

1. Using a Tech 2, display the MAP sensor value.

2. Check for a faulty, plugged, or incorrectly installed

MAP sensor.

Was the problem found?

—

Verify repair

Go to Step 9

9

If oscilloscope is available, check the wave form of the

CKP signal.

Was the correct wave form found?

—

Go to Step 12

Go to Step 10

10

Check the CKP sensor wire for open or short circuit.

Was a problem found?

—

Verify repair

Go to Step 11

11

Replace CKP sensor.

Is there still problem?

—

Replace pulsar

ring.

Verify repair